2.7

Lead/Lag Control

The chiller may be set up for AUTO or MANUAL

lead/lag. This is accomplished by programming the

option under the 'OPTIONS' key.

When AUTO lead/lag is used, the microprocessor

attempts to balance run time between the systems. A

number of conditions can occur which will prevent this

from happening. Factors determining lead/lag selection

and the resulting lead/lag determination are:

The microprocessor automatically defaults the lead to

system 1 and the lag to system 2 if both systems are

ready to start (Anti-recycle Timers timed out) and the

systems have equal run time.

If both systems are waiting to start (Anti-recycle timers

have not timed out), the microprocessor will assign the

lead to the system with the shortest anti-recycle time to

provide cooling quickly.

If the lead system is locked out, faulted and waiting to

restart the lag system is swapped to the lead.

MANUAL lead/Lag selection will be automatically

overridden by the microprocessor to allow the lag

system to automatically become the lead anytime the

selected lead system shuts down due to, lead system

faults.

Automatic switch over in MANUAL mode is provided to

try to maintain chilled liquid temperature as close to

‘SETPOINT’ as possible.

2.8

Condenser Coil Fan Control

(YLAA & YLAE Units)

The fans are controlled by the discharge pressure.

There are two to four steps of fan discharge pressure

control plus step time control dependant on the number

of fans in a system. Subsequent to the compressor

starting, and if required by the discharge pressure, there

will be a time delay of 5 seconds before the first fan can

start. The delay between turning on and off fan stages is

fixed at 5 seconds. The controller increments or

decrements the fan stage by one stage at a time based

on the discharge pressure and the fan delay time. The

number of stages required is determined by the

discharge pressure. The number of fans in each system

is given in the table below.

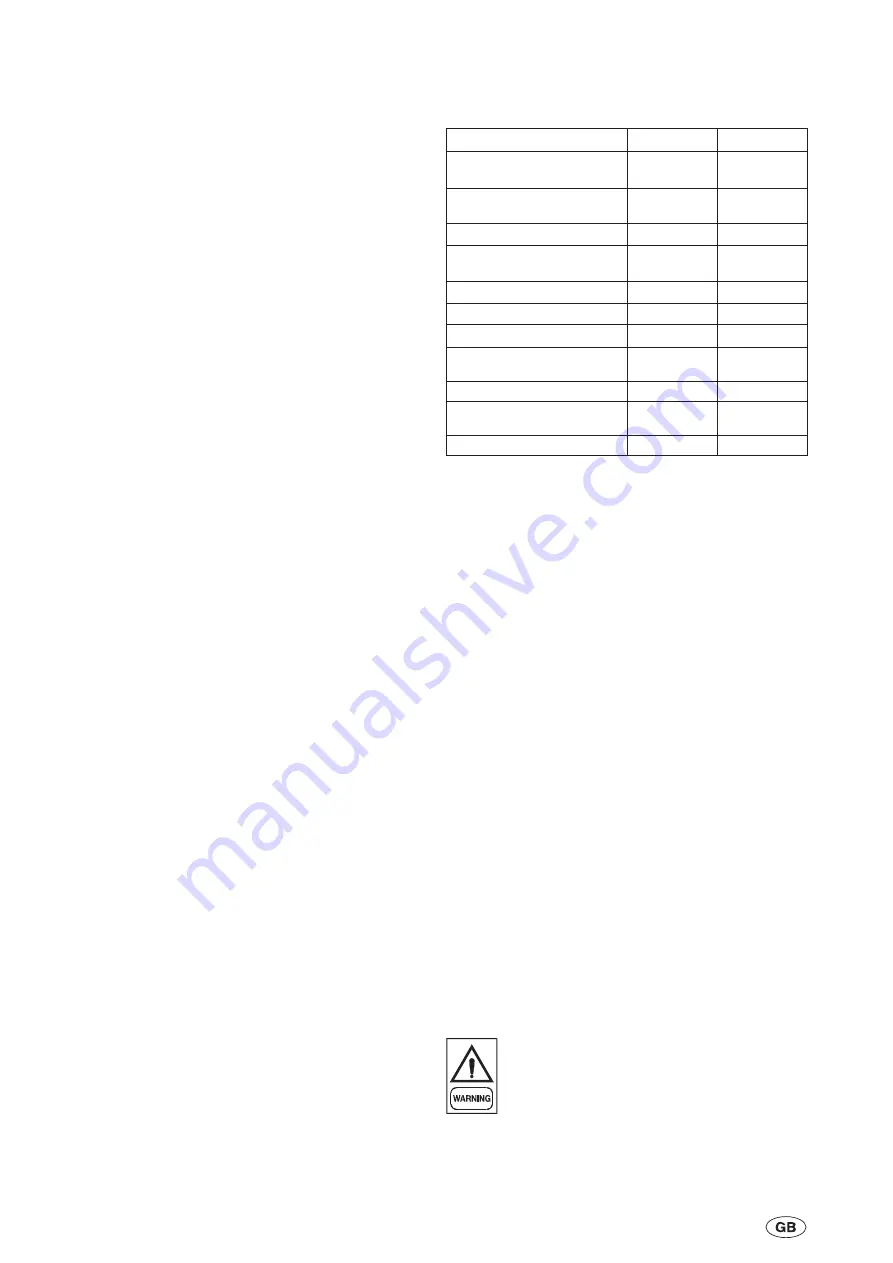

YLAA MODEL

SYSTEM 1

SYSTEM 2

0180SE to 320SE

0195HE to 0260HE

2

2

0360SE, 0400SE

0300HE

3

2

0390HE

4

2

0435SE, 0485SE

0350HE

3

3

0440HE

4

3

0455HE, 0515HE

4

4

YLAE MODEL

SYSTEM 1

SYSTEM 2

0190SE to 330SE

0195HE to 0265HE

2

2

0315HE

3

2

0375SE to 0490SE

0355HE to 0405HE

3

3

0465HE to 0510HE

4

4

Low Ambient Units

On systems with 2 or 3 fans, fan number 1 is replaced by

a variable speed fan. On system 2 of YLAA180SE,

195HE and 210SE the two small fans are replace by one

variable speed fan. The fan is not controlled by the

discharge pressure stages but is energized directly from

the fan fuses when the unit power is turned on. The fan

motor has a integral invertor which controls fan speed to

maintain a pressure between 18 and 22.5 barg. Below

18 barg the fan should be off, above 22.5 barg the fan

should be at full speed, with a linier response between

these two pressures. A separate 4-20ma pressure

transducer (-BFDP) is wired via a relay (-KF1) to the fan.

The relay energizes along with the liquid line solenoid to

connect the pressure transducer to the fan. When the

system is off, the transducer is disconnected and the fan

will stop. When the system is running the transducer is

connected to the fan and thus fan speed is based on

discharge pressure. The fan motor invertor has

integrated EMC filtering. The fan motor will restart

automatically after any of the following trips - Line failure

- Phase Failure - Line under Voltage - DC link voltage

too high or to low - Locked rotor. For trips on high motor

or motor electronics temperatures the fan motor will not

automatically reset. The 3 phase power to the fan motor

must be disconnected for at least one minute. If any

system is still running the system should be shutdown

on the system switches under the option key. The unit

disconnect switch must be open for one minute to allow

the fan electronics to reset.

DANGER OF ELECTRICAL SHOCK. The unit

disconnect switch must be opened for a

minimum of 5 minutes before the panel power

section or fan motor terminal cover is opened

to allow the the variable speed fans internal

power supply to decay to a safe level.

1

-

8

Form 201.26.OI1(11/09)