RWF ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

S70-600 IOM (OCT04)

Page 11

3.

The oil pump starter with fuses, or in the case where the

compressor motor is a different voltage from the oil pump

motor, with a circuit breaker disconnect suitable for sepa rate

power feed.

4.

A 2.0 KVA control power transformer (CPT) to supply 120

volt control power to the microprocessor control system and

separator oil heaters is included. If environ mental condi tions

require more than the usual two 500 watt oil heaters, an ap-

propriately oversized control transformer will be required. If

frequent power fluc tuations are anticipat ed or extremely noisy

power lines are encoun tered, a regulating control transformer

should be considered. Contact FRICK for assistance.

5.

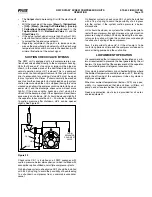

For customer-supplied across-the-line starters, a shunt-

ing device must be installed across the Current Transformer

(terminals 3 & 4).

If the shunting device is not in-

stalled, the Analog I/O board on the

Quantum

™

panel may be severly

damaged at start-up (see Figure 10).

Figure 10 - STARTER WIRING DIAGRAM

6.

One each normally open compressor motor and oil pump

motor starter auxiliary contact should be supplied. In addition

to the compressor and oil pump motor starter coils, the CT

and CPT secondaries should be wired as shown on the start-

er package wiring diagram. The load on the control panel for

the compressor motor starter coil should not exceed a Nema

size 3 starter. For larger starters, an interposing relay must

be used to switch the compres sor motor starter coil(s).

NOTE: Do not install a compressor HAND/OFF/AUTO

switch in the starter package as this would bypass the

compressor safety devices.

7.

The compressor motor Current Transformer (CT) is in-

stalled on any one phase of the compressor leads.

NOTE: The CT must see all the current of any one phase,

therefore in wye-delta applications BOTH leads of any

one phase must pass through the CT.

CURRENT TRANSFORMER (CT) RATIOS

The CT ratio for various motor sizes (with a 5 amp second-

ary) is given in the following table:

VOLTAGE

HP

200

230

380

460

575

2300 4160

20

100:5 100:5 50:5

50:5

50:5

-

-

25

100:5 100:5 50:5

50:5

50:5

-

-

30

200:5 100:5 100:5 50:5

50:5

-

-

40

200:5 200:5 100:5 100:5 50:5

-

-

50

200:5 200:5 100:5 100:5 100:5

-

-

60

300:5 200:5 200:5 100:5 100:5

-

-

75

300:5 300:5 200:5 200:5 100:5

-

-

100

400:5 300:5 200:5 200:5 200:5

-

-

125

500:5 400:5 300:5 200:5 200:5

-

-

150

600:5 500:5 300:5 300:5 200:5

-

-

200

800:5 600:5 400:5 300:5 300:5 100:5 50:5

250

800:5 800:5 500:5 400:5 300:5 100:5 50:5

300 1000:5 1000:5 600:5 500:5 400:5 100:5 50:5

350

-

1000:5 800:5 500:5 500:5 100:5 100:5

400

-

-

800:5 600:5 500:5 200:5 100:5

450

-

-

1000:5 800:5 600:5 200:5 100:5

500

-

-

1000:5 800:5 600:5 200:5 100:5

600

-

-

1200:5 1000:5 800:5 200:5 100:5

700

-

-

-

1200:5 1000:5 200:5 200:5

800

-

-

-

-

1000:5 300:5 200:5

900

-

-

-

-

1200:5 300:5 200:5

1000

-

-

-

-

-

300:5 200:5

1250

-

-

-

-

-

400:5 200:5

1500

-

-

-

-

-

500:5 300:5

MINI MUM BURDEN RATINGS

The following table gives the minimum CT burden ratings.

This is a function of the distance between the motor starting

package and the compressor unit.

BURDEN

MAXIMUM DISTANCE FROM

RATING

FRICK PANEL

USING #

USING #

USING #

ANSI

VA

14 AWG

12 AWG

10 AWG

B-0.1

2.5

15 ft

25 ft

40 ft

B-0.2

5

35 ft

55 ft

88 ft

B-0.5

12.5

93 ft

148 ft

236 ft

Содержание Frick RWF 100

Страница 40: ...RWF ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 600 IOM OCT04 Page 40 P I DIAGRAM ...

Страница 43: ...RWF ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 600 IOM OCT04 Page 43 P I DIAGRAM LIQUID INJECTION BOOSTER ...

Страница 52: ...RWF ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 600 IOM OCT04 Page 52 OPERATING LOG SHEET ...

Страница 57: ...RWF ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 600 IOM OCT04 Page 57 ...