RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM (OCT04)

Page 55

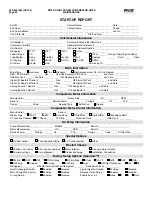

Adjustable Safety Setpoints

High Discharge Pressure Stop Load _____ Force Unload _____ Alarm ______ Delay ______ Shutdown _____ Delay _____

High Discharge Temp.

Stop Load _____ Force Unload _____ Alarm ______ Delay ______ Shutdown _____ Delay _____

Motor Amps ______ Volts ______ Service Factor _______ Horsepower________ CT Factor ______ Recycle Delay _______

Low Motor Amps

Shutdown ______ Delay ______ Force Unload Inhibit Delay _______

High Motor Amps

Stop Load _____ Force Unload _____ Alarm ______ Delay ______ Shutdown _____ Delay _____

High Oil Temperature

Alarm _______ Delay ______ Shutdown ______ Delay ______

Low Oil Temperature

Alarm _______ Delay ______ Shutdown ______ Delay ______ High Level Shutdown Delay _____

Low Separator Oil Temp. Alarm _______ Delay ______ Shutdown ______ Delay ______

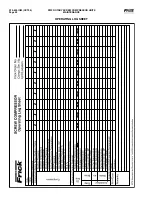

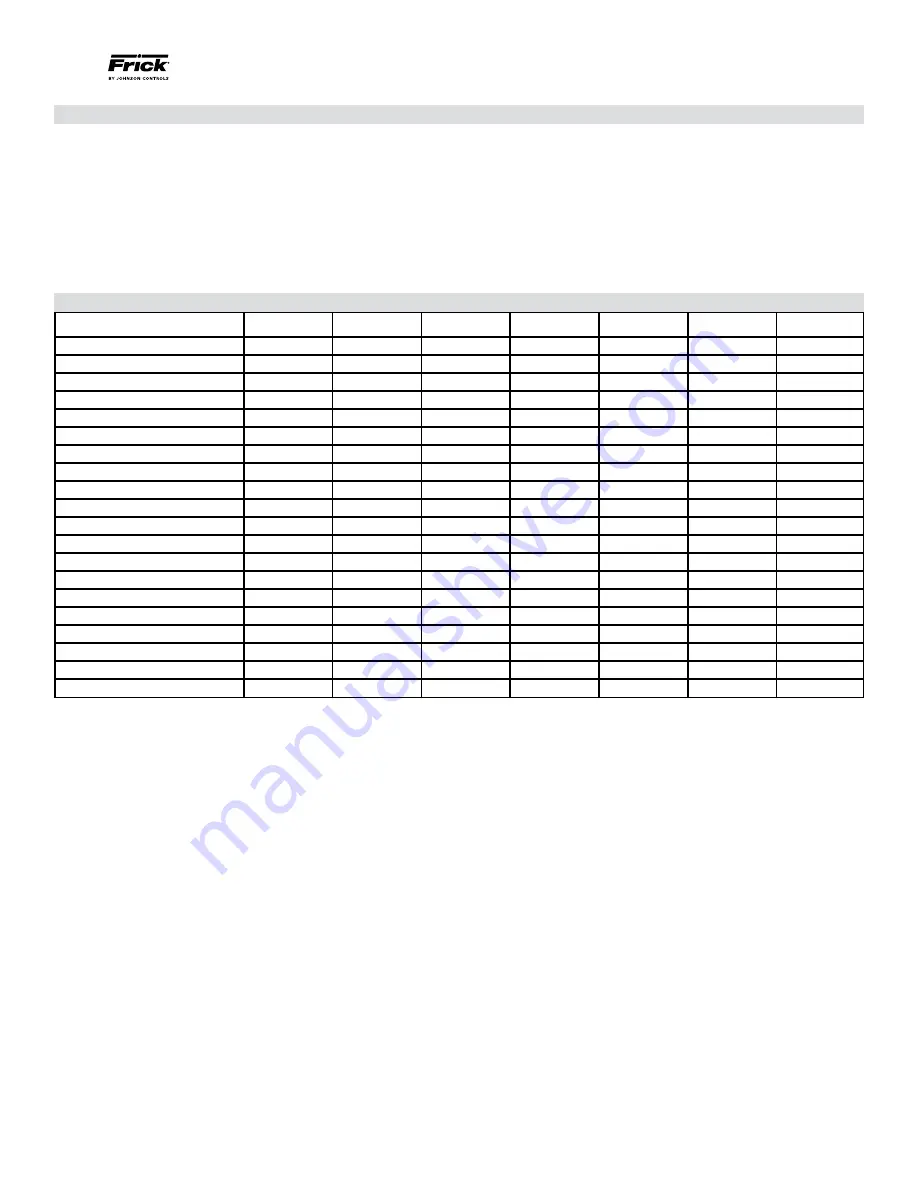

Operating Log Sheet

Date

Time

Hour Meter Reading

Equip. Room Temp.

Suction Pressure

Suction Temperature

Suction Superheat

Discharge Pressure

Discharge Temperature

Corresponding Temperature

Oil Pressure

Oil Temperature

Oil Filter Pressure Drop

Separator Temperature

Slide Valve Position

Volume Ratio (VI)

Motor Amps / FLA %

Capacity Control Setpoint

Oil Level

Oil Added

Seal Leakage (Drops/Min.)

Содержание Frick RWF 100

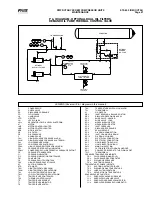

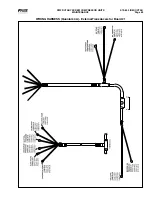

Страница 40: ...RWF ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 600 IOM OCT04 Page 40 P I DIAGRAM ...

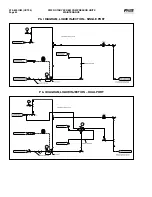

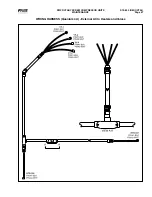

Страница 43: ...RWF ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 600 IOM OCT04 Page 43 P I DIAGRAM LIQUID INJECTION BOOSTER ...

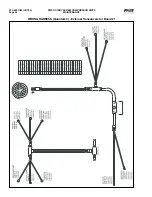

Страница 52: ...RWF ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 600 IOM OCT04 Page 52 OPERATING LOG SHEET ...

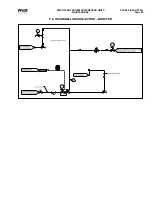

Страница 57: ...RWF ROTARY SCREW COMPRESSOR UNITS MAINTENANCE S70 600 IOM OCT04 Page 57 ...