SECTION 6 - EMERGENCY PROCEDURES

6-2

– JLG Lift –

3120889

func tions. Training should inc lud e o p eratio n o f the

machine, review and understanding of this section and

hands-on operation of the controls in simulated emergen-

cies.

Operator Unable to Control Machine

IF THE PLATFORM OPERATOR IS PINNED, TRAPPED

O R U N AB LE T O O P E R AT E O R C O N T R O L T H E

MACHINE:

DO NOT OPERATE WITH PRIMARY POWER SOURCE (ENGINE) IF

PERSONS ARE PINNED OR TRAPPED. USE AUXILIARY POWER

INSTEAD.

1.

Operate the machine from ground controls ONLY

with the assistance of other personnel and equip-

ment (cranes, overhead hoists, etc.) as may be

required to safely remove the danger or emergency

condition.

2.

Other qualified personnel on the platform may use

the platform controls with regular or auxiliary power.

DO NOT CONTINUE OPERATION IF CONTROLS

DO NOT FUNCTION NORMALLY.

3.

Cranes, forklift trucks or other equipment which may

be available are to be used to remove platform

occupants and stabilize motion of the machine in

case machine controls are inadequate or malfunc-

tion when used.

Platform or Boom Caught Overhead

If the platform or boom becomes jammed or snagged in

overhead structures or equipment, do not continue opera-

tion of the machine from either the platform or the ground

until the operator and all personnel are safely moved to a

secure location. Only then should an attempt be made to

free the platform using any necessary equipment and per-

sonnel. Do not operate controls to cause one or more

wheels to leave the ground.

Righting a Tipped Machine

No attempt should be made to right the machine using

platform or g round c ontrols. A fork truc k of suitab le

capacity or equivalent equipment may be placed under

the elevated side of the chassis. A crane or other lifting

equipment may also be used to lift the platform while the

chassis is lowered by a fork truck, jacks, or other means.

Remove all p ersonnel and eq uip ment from the area

before starting operation.

Post Incident Inspection and Repair

Following any incident, thoroughly inspect the machine

and test all functions first from the ground controls, then

from the platform controls. Do not lift above 10 feet (3 m)

until you are sure that all damage has been repaired, if

required, and that all controls are operating correctly.

6.5

INCIDENT NOTIFICATION

It is imperative that JLG Industries, Inc. be notified imme-

diately of any incident involving a JLG product. Even if no

injury or property damage is evident, the factory should

be contacted by telephone and provided with all neces-

sary details.

Contact your local JLG office.

It should be noted that failure to notify the manufacturer of

an incident involving a JLG Industries product within 48

hours of such an occurrence may void any warranty con-

sideration on that particular machine.

Содержание 100HX

Страница 2: ...Courtesy of Crane Market...

Страница 4: ...FOREWORD b JLG Lift 3120889 This page left blank intentionally Courtesy of Crane Market...

Страница 6: ...FOREWORD d JLG Lift 3120889 REVISON LOG January 1999 Original Issue Courtesy of Crane Market...

Страница 10: ...iv JLG Lift 3120889 TABLE OF CONTENTS Continued This page left blank intentionally Courtesy of Crane Market...

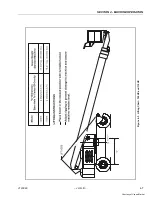

Страница 66: ...SECTION 4 MACHINE OPERATION 4 8 JLG Lift 3120889 Figure 4 4 Lifting Chart 100HX 10 Courtesy of Crane Market...

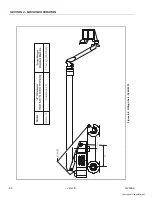

Страница 69: ...SECTION 4 MACHINE OPERATION 3120889 JLG Lift 4 11 Figure 4 5 Machine Tie Down Courtesy of Crane Market...

Страница 78: ...Courtesy of Crane Market...

Страница 79: ...Courtesy of Crane Market...