SECTION 2 - PREPARATION AND INSPECTION

2-8

– JLG Lift –

3120889

2.5

DAILY FUNCTIONAL CHECK

THE LOAD MANAGEMENT SYSTEM AND THE AXLES (PROPER

EXTENSION AND RETRACTION) MUST BE CHECKED PRIOR TO

ANY OTHER SYSTEMS AND/OR FUNCTIONS.

A functional check of all systems should be performed,

once the walk-around inspection is complete, in an area

free of overhead and ground level obstructions. First,

using the ground controls, check all functions controlled

by the ground controls. Next, using the platform controls,

check all functions controlled by the platform controls.

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY

CONTROL LEVERS OR TOGGLE SWITCHES CONTROLLING

PLATFORM MOVEMENTS DO NOT RETURN TO THE OFF OR NEU-

TRAL POSITION WHEN RELEASED.

TO AVOID COLLISION AND INJURY IF PLATFORM DOES NOT

STOP WHEN A CONTROL SWITCH OR LEVER IS RELEASED,

REMOVE FOOT FROM FOOTSWITCH OR USE EMERGENCY STOP

TO STOP THE MACHINE.

NOTE: Perform checks from ground controls first, where

applicable, then from platform controls.

1.

Axles, Extending and Retracting.

a. From the ground control, activate the machine

hydraulic system and raise the boom. Extend

the boom no more than 2.4 m (8 feet).

b. Position STEER/AXLES valve, located at the

front of the frame to AXLES.

c. Position boom over drive wheel end of machine.

Remove axle lock pins.

D O N O T U SE EX T E N D - A - R EA C H ( I F E QU I P PED ) TO L I FT

MACHINE WHEN EXTENDING AND RETRACTING AXLES.

d. Position LIFT control to DOWN and hold until

drive wheels rise from the ground; it may be nec-

essary to feather the lift control to maintain drive

wheel elevation.

e. With the aid of an assistant, position EXTEND-

ABLE AXLE/STEER switch located on platform

control console to EXTEND until axles are fully

extended and the AXLES SET light is on. Install

axle lock pins.

f.

Position LIFT control to UP to lower the

machine; elevate the boom sufficiently and repo-

sition the boom over the steer wheel end of the

machine.

g. Remove the tie rod lock pins, steer cylinder lock

pin, and axle lock pins.

h. Position LIFT control to DOWN and hold until the

steer wheels rise from the ground; it may be

necessary to feather the LIFT control to maintain

wheel elevation.

i.

With the aid of an assistant, position EXTEND-

ABLE AXLE/STEER switch on platform console

to EXTEND until axles are fully extended.

j.

Align steer wheels and insert tie rod lock pin,

axle lock pins, and steer cylinder lock pins.

k. Position LIFT control to UP to lower the machine

steer wheels; position STEER/AXLES valve to

STEER.

l.

Cycle the steer system in both directions to

ensure the tie rods are properly locked.

m. Remove any one of the axle lock pins. From the

ground control, monitor the AXLES SET indica-

tor and attempt to lift and telescope the boom.

With an axle lock pin removed, you will not be

able to lift the boom above horizontal or tele-

scope out beyond 3.5 m (11.5 feet). At these

positions, the AXLES SET indicator will not light,

ind ic ating th e axles are n o t exten d ed and

locked. If the light does not illuminate when the

axl e s ar e e xt en d e d an d s e t an d t h e p i n s

installed, contact a qualified service technician

before continuing operation.

Содержание 100HX

Страница 2: ...Courtesy of Crane Market...

Страница 4: ...FOREWORD b JLG Lift 3120889 This page left blank intentionally Courtesy of Crane Market...

Страница 6: ...FOREWORD d JLG Lift 3120889 REVISON LOG January 1999 Original Issue Courtesy of Crane Market...

Страница 10: ...iv JLG Lift 3120889 TABLE OF CONTENTS Continued This page left blank intentionally Courtesy of Crane Market...

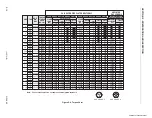

Страница 66: ...SECTION 4 MACHINE OPERATION 4 8 JLG Lift 3120889 Figure 4 4 Lifting Chart 100HX 10 Courtesy of Crane Market...

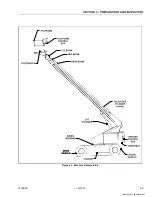

Страница 69: ...SECTION 4 MACHINE OPERATION 3120889 JLG Lift 4 11 Figure 4 5 Machine Tie Down Courtesy of Crane Market...

Страница 78: ...Courtesy of Crane Market...

Страница 79: ...Courtesy of Crane Market...