19

EHB-8VS | EHB-8VSM

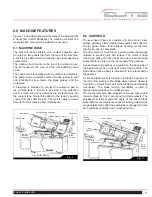

13.3 REPLACING THE DRIVE MOTOR

Referring to Figure 24:

1. Remove the drive belt (see

Changing the Drive

Belt

above).

2. Open the motor junction box and disconnect the

power cord wires from their terminals.

3. Remove

four

screws

and

washers

(A) that secure the

motor

(B) to the

mounting plate

(C).

4. Installation of a new motor is a reversal of the above

steps. Also, refer to

Changing the Drive Belt

(page 18)

to complete tensioning of the drive belt.

14.0 CLEANING

1.

Clean off any preservative on machine surfaces.

After

cleaning:

2.

Coat machined surfaces of the cutoff saw with a

medium consistency machine oil. Reapply the oil

coating at least every six months.

3.

Clean up accumulated saw cuttings after use. Make

sure the lead screw and rapid nut are kept free from

saw cuttings and other material that would cause

damage.

15.0 LUBRICATION

Lubricate the following components at the specified

frequencies and using the lubricants defined as follows:

Ball Bearings

– the bearings are lubricated and sealed –

periodic lubrication is not required.

Blade Guide Bearing

– the bearings are lubricated and

sealed – periodic lubrication is not required.

Upper Wheel Bushing

– six to eight drops of oil each week.

Pivot Points, Shafts, and Bearing areas

– six to eight drops

of oil each week.

16.0 COOLANT

Change coolant on a frequency appropriate to the type of

coolant being used. Oil based coolants can sour. Refer to

the coolant supplier’s instructions for change frequency.

The general-purpose coolant is a mixture of water-soluble

oil and water. Mix one part of soluble oil to ten parts of

water (one quart of oil to ten quarts water). Eleven quarts

of coolant is the amount required for the coolant pump to

operate properly.

There are numerous coolants on the market that are

formulated for special applications. Consult your local

distributor for details in the event you have a long range

production task, or are required to cut some of the more

exotic materials.

4. Clean the chip sludge from the coolant tank. The

frequency should be determined by how often the

saw is used.

!

Disconnect the cut-off saw from its electrical

power source.

Fig. 24

A

C

B