12

8-in x 13-in Horizontal Cut-Off Bandsaw

To start the saw:

1. Clamp the workpiece in the vise. Refer to Figures 10

and 11 for examples of workpieces in the vise.

Be sure the blade is not in contact with the workpiece

when the motor is started.

2. Start the motor and allow the saw to come up to

speed.

3. Slowly set the saw down onto the workpiece and

adjust cutting speed with the speed control knob

(described on page 9).

4. Do not drop the saw head or force the cut.

Let the weight of the saw head provide the

cutting

force.

5. The saw will automatically shut off at the end of the

cut.

11.8 COOLANT FLOW AND NOZZLE POSITION

Adjust the coolant flow shut-off valves at the top of the saw

head weldment. The flow should be no more than the saw

blade can draw into the workpiece by the movement of the

blade.

The coolant flow can be stopped in two ways:

•

by the coolant selector switch (A, Fig. 4) on the control

box (the preferred method)

•

by closing the shut-off valves

Note: The coolant pump is self-circulating when the

shut-off valves are closed.

!

Never operate the saw without blade covers in place.

!

CAUTION

Make sure the blade is not in contact with the

workpiece when the motor is started. Do not drop

the saw head on the workpiece or force the saw

through the workpiece.

!

CAUTION

The coolant pump must be submerged before

operating to prevent damage to the pump.

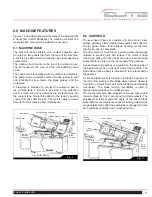

11.5 SETTING THE VISE FOR SQUARE CUTS

The procedure for setting the vise for square cuts is identical

to setting for angle cuts (above) except that a machinist’s

square is used to set the angle of the fixed vise jaw (A, Fig.

10). Align one side of the square with the side of the slot (B,

Fig. 10) in the table.

11.6 SETTING BED FOR MITERING CUTS

(MITERING VERSION ONLY)

The saw head can be adjusted through a 45-degree arc as

follows:

1. Ensure that power is turned off and then loosen saw

head miter lock.

2. Rotate the saw head to the approximate desired angle

as specified on the miter angle gauge. Then verify the

exact angle with Engineers square.

3. Lock the saw head miter lock. The miter locking lever

extends through a slot in the front face of the saw bed.

Rotate the lever to the right to tighten the lock and to

the left to loosen.

4. Load the work piece and continue with steps below.

11.7 STARTING THE SAW

Important: The efficient operation of the cut-off saw is de-

pendent upon the condition of the saw blade. If the perfor-

mance of the saw begins to deteriorate, the first item that

you should check is the blade.

If a new blade does not restore the machine’s cutting

accuracy and quality, refer to the

Troubleshooting

section (or

the blade manufacturer’s guide) for conditions to consider

and adjustments that can be made to increase the life of

the blade.

To change the blade, refer to the

Changing Blades

section

on page 17.

Fig. 10

A

B