14

8-in x 13-in Horizontal Cut-Off Bandsaw

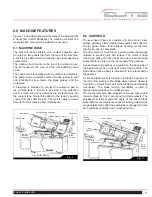

8. Turn the

adjustment screws

(F) to stop the motion of

the blade on the wheel as it gets closer to the wheel

shoulder.

Put a 6-inch length of paper (J, Fig. 14) between the

blade and the wheel as shown (the saw is still turned

on). The paper should not be cut as it passes

between the wheel shoulder and the blade.

9. Turn the

adjustment screws

(F) slightly.

Repeat the insertion of the paper between the wheel

shoulder and the blade until the paper is cut in two

pieces.

6. Start the saw. Turn the

adjustment screws

(F) to tilt

the idler wheel (Figure 14) until the blade is touching

the shoulder of the idler wheel.

Note: As a general rule, make the same adjustment to

the two adjustment screws on the right (F, Fig. 13). The

single adjustment on the left is independent.

7. Next, turn the

adjustment screws

(F) so the blade

starts to move away from the shoulder of the wheel

then immediately turn the

adjustment screws

in the

other direction so the blade stops – then moves slowly

toward the shoulder.

Note: You may have to repeat the check with the paper

several times before the blade and the shoulder cut the

paper into two pieces. Do not hurry the adjustment.

Patience and accuracy here will pay off with better, more

accurate, quieter cutting and much longer machine and

blade life.

When the paper is cut:

10. Turn the

adjustment screws

(F) slightly in the counter-

clockwise direction. This ensures that the blade is

not touching the shoulder of the wheel.

11. Shut off the saw.

12. Tighten the

hex locking screws

(E).

13. Install the

blade-guide bearing bracket assemblies

(C, Fig. 13).

14. Position the guides so the top bearing just touches

the blade (see

Blade Guide Bearing Adjustment

on

page 16) .

15. Close the

wheel covers

(K, Fig. 15).

!

CAUTION

While performing the following, keep the blade from

rubbing excessively on the shoulder of the wheel.

Excessive rubbing will damage the wheel and/or the

blade.

!

Keep fingers clear of the blade and wheel to

avoid injury.

Fig. 14

Lifting

Handle

Blade

Tension

Handwheel

Idler Wheel

J, Place paper here

Fig. 13

C

D

1

1

2

2

G

E,F

E,F

E

F

G

A

B