16

Connect the applicator to the tow vehicle using a hitch pin and make sure a retaining pin is secured in the

hitch pin. Always attach the safety chains to the applicator and the tow vehicle.

WARNING

–

Before unhooking the applicator, empty contents from tank, block wheels, unpin

the jack from storage position, and lock it in the usage position. Lower the jack stand to the ground

until the weight of the applicator is transferred to the jack. Keep hands and feet away from the jack

stand when lowering.

Remove the hitch pin and unhook the safety chains.

WARNING

–

Always relieve hydraulic system pressure before disconnecting hoses from tractor

or servicing hydraulic system. See the tractor’s operating manual for proper procedures. Disconnect the hydraulic hoses. Install

dust covers over the hose plugs and outlets.

When not in use, the jack handle is stored under the tongue, as

pictured to the right.

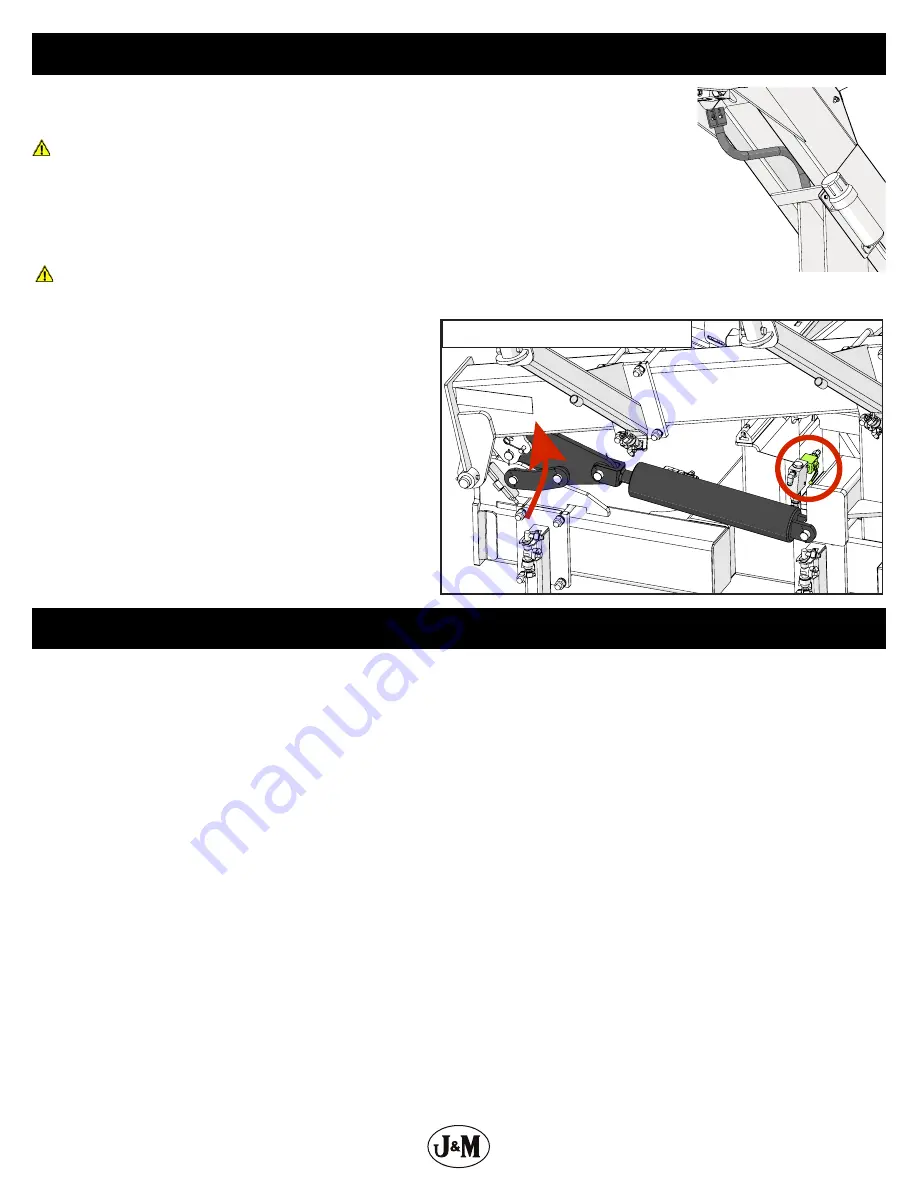

When not in use, lock the stub wing in place with the keeper pin

provided. This will keep the stub wings from unfolding when

temperatures fluctuate and cause thermal expansion in the

hydraulic system.

Hitching and Unhitching the Applicator

Follow these maintenance guidelines during the initial operation of your NitroGro applicator.

First 30 minutes of operation:

1. Ensure all coulters and nozzles are clean and working properly. Clean and adjust accordingly.

2. Check all hydraulic and chemical lines. Be sure none of them are kinked, pinched or leaking. Adjust lines accordingly.

3. Re-torque all of the wheel bolts.

4. Check all other fasteners and hardware. Adjust accordingly.

5. Lubricate all grease fittings.

6. Ensure that outside wings are not creeping up. If needed, adjust the counterbalance valves. Refer to “Counterbalance Valve” on page

15 for instructions.

After 4 hours of operation:

1. Ensure all coulters and nozzles are clean and working properly. Clean and adjust accordingly.

2. Check all hydraulic and chemical lines. Be sure none of them are kinked, pinched or leaking. Adjust lines accordingly.

3. Re-torque all of the wheel bolts.

4. Check all other fasteners and hardware. Adjust accordingly.

After 10 hours of operation:

1. Ensure all coulters and nozzles are clean and working properly. Clean and adjust accordingly.

2. Check all hydraulic and chemical lines. Be sure none of them are kinked, pinched or leaking. Adjust lines accordingly.

3. Re-torque all of the wheel bolts.

4. Check all other fasteners and hardware, especially the U-bolts that secure the coulters to the toolbar. Tighten if needed.

Upon completing the initial break-in period, begin the standard maintenance schedule as described in “Service” on page 24.

Initial Operation

Shut-off valve on Stub wing

Содержание 6018

Страница 2: ...2...

Страница 12: ...12 NitroGro Components...