© Intatec Ltd 2017

4

Pumped Systems

Pumped systems use a booster pump to increase the

pressure of the gravity fed water supplies.

These booster pumps are used where the head of

water is insufficient to provide a satisfactory shower

or where a high performance shower is required.

Please ensure that the performance of the pump is

matched to suit the shower.

Follow the instructions for gravity fed installations

taking into account the installation requirements of

the pump.

Ensure that the hot and cold water storage capacity

is sufficient to supply the shower and any other

draw off points that may be used simultaneously.

Most pumps require a minimum head of water to

allow the flow switches to operate automatically.

Where this is not available a negative head kit

may be required to operate the pump.

Please consult the pump manufacturer’s installation requirements

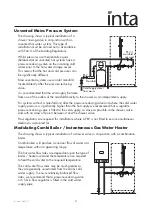

Gravity System

The drawing shows a typical installation of a

shower valve on a gravity supplied system.

Please note the minimum head pressure required

to ensure correct operation of the valve. In

accordance with good plumbing practice, we

recommend that a totally independent hot and

cold water supply be taken to the valve.

The cold water supply must be connected directly

to the water cistern. The hot water supply should

be connected to the hot water cylinder via an

Essex flange or Sussex flange or to the vent or a

draw off pipe as close as possible to the top of

the cylinder.

For equal tank fed pressures there is no need to

fit the flow regulators. This installation is the

recommended minimum for gravity supplies. For

systems with less than 2 metre head pressure,

we recommend that a suitable booster pump is

fitted to increase the supply pressure.

Cold Supply direct

from mains

Pumps

Option shown

for mains

pressure cold

& low pressure

hot water

Min. 2m head

Содержание Nulo CB10031CP

Страница 19: ...Intatec Ltd 2017 18 Notes...