© Intatec Ltd 2017

1

Introduction

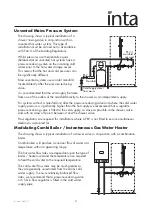

This installation guide has been produced for the Nulo shower mixing valve. These instructions

cover the installation, operation and maintenance. Please read the enclosed instructions before

commencing the installation of this product, please note;

We recommend that the installation of any Inta product is carried out

by an approved installer.

The installation must be carried out strictly in accordance with the Water Supply (Water Fitting)

Regulations 1999 and any local authority regulations.

If in doubt we recommend that you contact WRAS - Water Regulations Advisory Scheme on

Tel: 0333 207 9030, your local water authority - details available on the WRAS website or

the Chartered Institute of Plumbing and Heating Engineers on Tel: 01708 472 791.

All products MUST be re-commissioned to suit site conditions to ensure optimum performance

levels of the product are obtained

Safety

This thermostatic shower must be installed and commissioned correctly to ensure that water is

supplied at a safe temperature to suit the users.

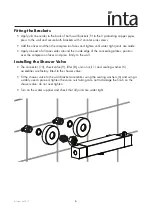

The shower is pre-set using ideal conditions to 38°C at the stop with a manual push button

override to 46°C (can be re-set to suit site conditions or user preference – see calibration

page 7).

The maximum mixed temperature takes account of the allowable tolerances inherent in

thermostatic shower mixers and temperature losses.

It is not a safe bathing temperature for adults or children

.

The British Burns Association recommends 37 to 37.5˚C as a comfortable bathing

temperature for children. In premises covered by the Care Standard Act 2000, the maximum

mixed water outlet temperature is 43˚C

Products

Nulo Safe-touch Thermostatic Bar Shower with Flexible Slide Rail Kit.

CB10031CP

Nulo Deluxe Safe Touch Thermostatic Bar Shower with Flexible

Slide Rail Kit, Smooth Hose and Push Button Handset

CB10035CP

Nulo Safe-touch Thermostatic Bar Shower - valve only

ED10045CP

Check Content

Before commencing remove all components from packaging and check each component with

the contents list.

Ensure all parts are present, before discarding any packaging. If any parts are missing, do not

attempt to install your Inta shower valve until the missing parts have been obtained.

Содержание Nulo CB10031CP

Страница 19: ...Intatec Ltd 2017 18 Notes...