© Intatec Ltd 2017

15

Installation

3. The supply to which the thermostatic shower valve is to be installed must be thoroughly

flushed and cleaned to remove any debris, which may have accumulated during the

installation. Failure to remove any debris will affect the performance and the manufacturer’s

warranty of the product. In areas that are subject to aggressive water, provision must be

made to treat the supplies prior to the supplies entering the shower valve.

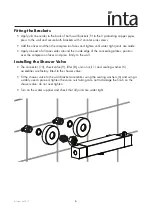

4. The thermostatic shower valve has been designed for horizontal installation and surface

mounting.

5. The thermostatic shower valve will be installed in such a position that maintenance of it’s

components, associated valves and the commissioning and testing of the shower valve can

be undertaken.

6. The hot and cold water supplies must be connected to the valve strictly in accordance with

the indications on the body of the valve i.e. hot water supply to the hot port of the valve.

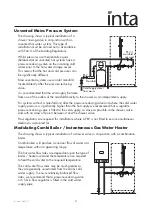

7. In a situation where one or both of the water supplies are excessive, it is recommended to fit

a Pressure Reducing Valve to reduce the pressure(s) to within the limits as quoted previously.

8. Any thermostatic shower valve must be fitted with a back flow prevention device, such as

check valves to prevent the cross contamination of supplies. The thermostatic shower valve

is supplied complete with integral insert check valves and strainers.

9. Isolation valves in an accessible position are required as close as is practicable to the water

supply inlets of the thermostatic shower valve.

10. The fitting of strainers is recommended as close as is practicable to the water supply inlets of

the thermostatic shower valve.

11. It is essential that the fail safe thermostatic shower valve should not be installed in situations

where there is a possibility of the valve being deprived of water or where demands for

water are greater than the actual stored supplies.

12. To ensure that the performance levels of the thermostatic shower valve are maintained (in

the event of cold water failure), the temperature of the hot water supply at the point of entry

to the thermostatic shower valve must be a minimum of 10˚C above the commissioned

mixed water discharge temperature.

13. The fail-safe thermostatic shower valve must not be subject to any extreme temperature

variations either during the installation or under normal operating conditions.

Содержание Nulo CB10031CP

Страница 19: ...Intatec Ltd 2017 18 Notes...