35

3-11

+

+

3

12

1

P1

2

P3

3

12

P1

1

2 P3

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

3.10 CONVERTING THE BOILER TO

OTHER TYPES OF GAS.

If the boiler has to be converted to a different gas

type to that specified on the data plate, request

the relative conversion kit for quick and easy

conversion.

The gas conversion operation must be carried

out by an authorised company (e.g. Immergas

After-Sales Technical Assistance Service).

To convert to another type of gas the following

operations are required:

- disconnect the appliance;

- Change the sleeve with Venturi (det. 21 fig.

1-25);

- change the gas nozzle (det. 4 fig. 1-25);

- re-power the appliance;

- regulate the maximum heat output by varying

the number of fan revs. (parameter P25 “Max

number of fan revs in CH mode”) according to

par. 3.24;

- regulate the minimum heat output by varying

the number of fan revs. (parameter P26 “Min

number of fan revs in CH mode”) according to

par. 3.24;

- activate the chimney sweep function;

- check the CO

2

value on the table in par. 3.25,

especially:

- check the CO

2

value in the flue with chimney

sweep at 0%;

- check the CO

2

value in the flue with chimney

sweep at 100%;

- exit the chimney sweep function;

- seal the gas flow rate regulation devices (if

settings are modified);

- after completing the conversion, apply the

sticker, contained in the conversion kit, near

the data-plate. Using an indelible marker pen,

cancel the data relative to the old type of gas.

These adjustments must be made with reference

to the type of gas used.

3.11 CHECKS FOLLOWING

CONVERSION TO ANOTHER TYPE

OF GAS.

After making sure that transformation was

carried out with the Venturi and a nozzle of

suitable diameter for the type of gas used and

the calibration has been performed at the correct

num. of revs, check that:

- the burner flame is not too high and that it is

stable (does not detach from burner)

- there are no leaks from the gas circuit.

N.B.:

all boiler adjustment operations must

be carried out by a qualified technician (e.g.

Immergas After-Sales Assistance).

3.12 ADJUSTMENT OF THE AIR-GAS

RATIO.

Calibration of minimum CO

2

Turn the boiler on and start the chimney sweep

functions at minimum output (0%). To have an

exact value of CO

2

the technician must insert

the sampling probe to the bottom of the sample

point, then check that the CO

2

value is that

specified in the table in par. 3.25, on the con-

trary, regulate the screws (3 fig. 3-11) (Off-Set

regulator). To increase the CO

2

value, turn the

adjustment screw (3) in a clockwise direction and

vice versa to decrease it.

Calibration of maximum CO

2

.

When you finish the minimum CO

2

adjustment,

turn the boiler on and start the chimney sweep

function at the maximum output (100%). To have

an exact value of CO

2

the technician must insert

the sampling probe to the bottom of the sample

point, then check that the CO

2

value is that spec-

ified in the table in par. 3.25, otherwise, adjust

the screw (12 fig. 3-11) (gas flow rate regulator).

To increase the CO

2

value, turn the adjustment

screw (12) in an anti-clockwise direction and vice

versa to decrease it.

At every adjustment variation on the screw (12)

it is necessary to wait for the boiler to stabilise

itself at the value set (about 30 sec.).

3.13 CH OUTPUT ADJUSTMENT.

If it is necessary to change the CH output, you

will need to adjust the “P08” maximum CH out-

put and “P09” minimum CH output parameters.

To check the regulated heat output value, com-

pare the no. of fan revs with that in the table

(par. 3.24).

3.14 OUTPUT ADJUSTMENT DURING

DHW (ONLY IN COMBINATION

WITH AN OPTIONAL EXTERNAL

STORAGE TANK).

If it is necessary to change the DHW output,

you will need to adjust the “P20” maximum

DHW output and “P21” minimum DHW output

parameters.

To check the regulated heat output value, com-

pare the no. of fan revs with that in the table

(par. 3.24).

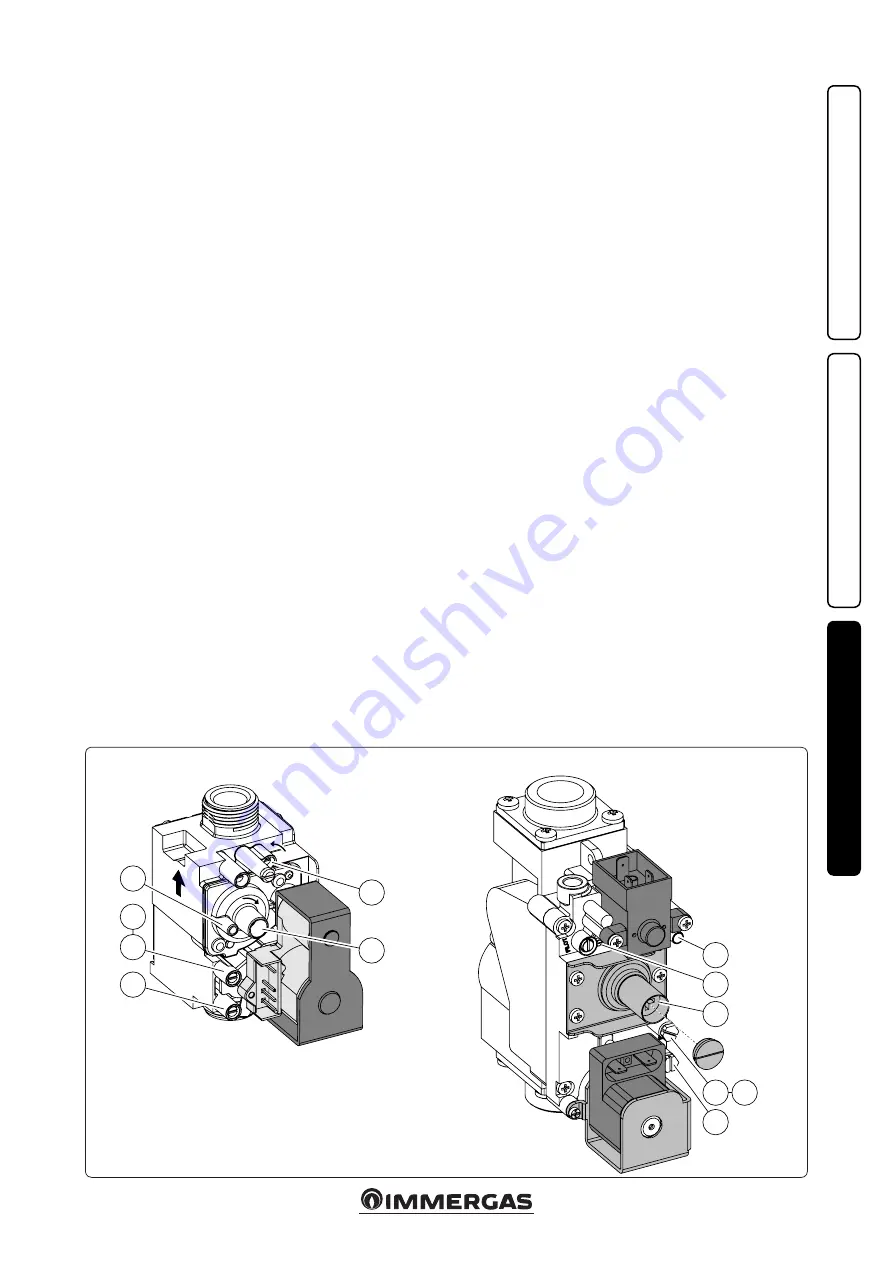

Key:

1 - Gas valve inlet pressure point

2 - Gas valve outlet pressure point

3 - Off/Set adjustment screw

12 - Outlet gas flow rate regulator

8222 Gas Valve (Victrix Pro 100 - 120 2ErP)

848 Gas Valve (Victrix Pro 80 2ErP)