40

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

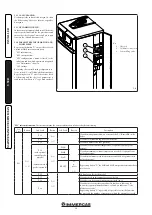

3.19 VARIABLE HEAT OUTPUT.

N.B.:

the pressures indicated in the table repre-

sent the differences of pressures at the ends of

the Venturi mixer and can be measured from the

pressure points in the upper part of the sealed

chamber (see pressure test 29 and 30 Fig. 1-28).

The adjustments must be made with a digital

differential pressure gauge with scale in tenths

of a mm or Pascal. The power data in the table

has been obtained with an intake-exhaust pipe

measuring 0.5 m in length. Gas flow rates refer

to the lower calorific value at a temperature of

15°C and at a pressure of 1013 mbar. The burner

pressure values refer to the use of gas at a tem-

perature of 15°C.

3.20 COMBUSTION PARAMETERS.

METHANE (G20)

BUTANE (G30)

PROPANE (G31)

THERMAL

POWER

THERMAL

POWER

BURNER GAS

FLOW RATE

PRESS. BURNER

NOZZLES

BURNER GAS

FLOW RATE

PRESS. BURNER

NOZZLES

BURNER GAS

FLOW RATE

PRESS. BURNER

NOZZLES

(kW)

(kcal/h)

(m

3

/h)

(mbar)

(mm H

2

O)

(kg/h)

(mbar)

(mm H

2

O)

(kg/h)

(mbar)

(mm H

2

O)

32,0

27520

3,49

1,94

19,8

2,61

2,30

23,5

2,57

2,59

26,4

31,0

26660

3,38

1,85

18,9

2,53

2,17

22,2

2,48

2,45

25,0

30,0

25800

3,27

1,76

17,9

2,44

2,05

20,9

2,40

2,32

23,6

29,0

24940

3,16

1,67

17,1

2,36

1,94

19,8

2,32

2,19

22,3

28,0

24053

3,05

1,58

16,2

2,27

1,82

18,6

2,24

2,06

21,0

27,0

23220

2,94

1,50

15,3

2,20

1,71

17,5

2,16

1,94

19,8

26,0

22360

2,83

1,42

14,5

2,11

1,61

16,4

2,08

1,82

18,6

25,0

21500

2,72

1,34

13,7

2,03

1,51

15,4

2,00

1,71

17,4

24,0

20640

2,62

1,26

12,9

1,95

1,41

14,4

1,92

1,60

16,3

23,0

19780

2,51

1,19

12,1

1,87

1,31

13,4

1,84

1,49

15,2

22,0

18920

2,40

1,11

11,3

1,79

1,22

12,5

1,76

1,39

14,2

21,0

18060

2,29

1,04

10,6

1,71

1,13

11,6

1,68

1,29

13,2

20,0

17200

2,19

0,96

9,8

1,63

1,05

10,7

1,60

1,19

12,2

19,0

16340

2,08

0,89

9,1

1,55

0,97

9,9

1,53

1,10

11,2

18,0

15480

1,97

0,82

8,4

1,47

0,89

9,1

1,45

1,01

10,3

17,0

14620

1,86

0,76

7,7

1,39

0,81

8,3

1,37

0,93

9,5

16,0

13760

1,76

0,69

7,0

1,31

0,74

7,6

1,29

0,84

8,6

15,0

12900

1,65

0,62

6,4

1,23

0,67

6,9

1,21

0,77

7,8

14,0

12040

1,54

0,56

5,7

1,15

0,61

6,2

1,13

0,69

7,0

13,0

11180

1,43

0,50

5,1

1,07

0,55

5,6

1,05

0,62

6,3

12,0

10320

1,33

0,44

4,4

0,99

0,49

5,0

0,97

0,55

5,6

11,0

9460

1,22

0,37

3,8

0,91

0,43

4,4

0,89

0,48

4,9

10,0

8600

1,11

0,32

3,2

0,83

0,38

3,8

0,82

0,42

4,2

9,0

7740

1,00

0,26

2,6

0,75

0,33

3,3

0,74

0,36

3,6

8,0

6880

0,89

0,20

2,1

0,67

0,28

2,8

0,66

0,30

3,1

7,0

6020

0,78

0,15

1,5

0,58

0,23

2,4

0,58

0,25

2,5

6,9

5934

0,77

0,14

1,4

0,58

0,23

2,3

0,57

0,24

2,4

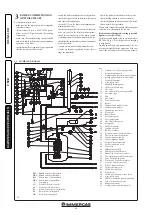

G20

G30

G31

Supply pressure

mbar (mm H

2

O)

20 (204)

29 (296)

37 (377)

Gas nozzle diameter

mm

WITHOUT

5,75

6.00

Flue flow rate at nominal heat output

kg/h (g/s)

51 (14,17)

47 (13,06)

52 (14,44)

Flue flow rate at min heat output

kg/h (g/s)

12 (3,33)

11 (3,06)

12 (3,33)

CO

2

at Q. Nom./Min.

%

9,60 / 8,70

12,10 / 11,30

10,70 / 10,00

CO with 0% O

2

at Nom./Min. Q. Nom./Min.

ppm

204 / 5

563 / 11

197 / 8

NO

X

at 0% of O

2

at Q. Nom./Min.

mg / kWh

72 / 20

188 / 66

59 / 27

Flue temperature at nominal output

°C

75

82

76

Flue temperature at minimum output

°C

63

70

64

Max air combustion temperature

°C

50

50

50

Combustion parameters: measuring conditions

of useful efficiency (flow temperature/return

temperature= 80/60 °C), ambient temperature

reference = 15°C.