30

3-1

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

3

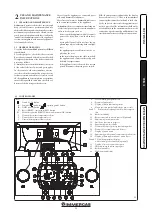

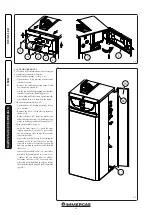

BOILER COMMISSIONING

(INITIAL CHECK)

To commission the boiler:

- make sure that the type of gas used corresponds

to boiler settings;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

- make sure the central heating system is filled

with water and that the pressure gauge indicates

a pressure of 1-1.2 bar.

- check that the the air vent valve cap is open and

that the system is well deaerated;

- switch the boiler on and check correct ignition;

- check the ∆p gas values in domestic hot water

and central heating modes;

- check the CO

2

in the fumes at maximum and

minimum flow rate;

- check activation of the safety device in the event

of no gas, as well as the relative activation time;

- check the intervention of the main switch

located upstream of the boiler and in the boiler;

- check that the intake and/or exhaust terminals

are not blocked;

- ensure activation of all adjustment devices;

- seal the gas flow rate regulation devices (if set-

tings are modified);

- check the production of domestic hot water;

- check sealing efficiency of water circuits;

- check ventilation and/or aeration of the instal-

lation room where provided.

If even only a single safety check offers a negative

result, do not commission the system.

Risk of material damage after using sprays and

liquids to search for leaks.

Leak sprays and liquids clog the reference hole

PR (Part. 4 Fig. 3-3) of the gas valve, damaging

it irreparably.

During installation and maintenance, do not

use spray or liquids in the upper area of the gas

valve (side referring to the electric connections).

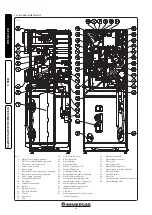

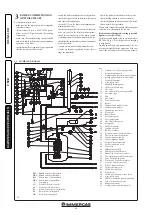

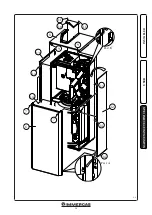

3.1 PLUMBING DIAGRAM.

Key

1 - Stainless steel coil for storage tank

2 - System draining valve

3 - Storage tank unit return one-way valve

4 - Polyphosphate dispenser (optional)

5 - System filling valve

6 - 3 bar safety valve

7 - Manifold draining valve

8 - Condensate drain trap

9 - Gas valve

10 - Gas valve outlet pressure point (P3)

11 - Air intake pipe

12 - Fan

13 - Gas nozzle

14 - Detection electrode

15 - Burner

16 - Condensation module covers

17 - Condensation module

18 - Manual air vent valve

19 - Flue probe

20 - Fumes hood

21 - Air sample point

22 - Flue sample point

23 - Gas ΔP pressure point

24 - Flow probe

25 - Safety thermostat

26 - Ignition electrode

27 - Boiler Circulator

28 - System pressure switch (absolute)

29 - Three-way valve (motorised)

30 - Venturi positive sign P1

31 - Venturi negative sign P2

32 - Air/gas Venturi manifold

33 - System expansion vessel

34 - Vent valve

35 - Hydraulic manifold

36 - Mixing valve mixed zone 2

37 - Mixed zone 2 system circulator

38 - Low temperature safety thermostat

39 - Zone 2 mixed flow probe

40 - Direct zone 1 system circulator

41 - One-way valve direct zone 1

42 - D.H.W. expansion vessel

43 - Cold water inlet cock

44 - Cold water inlet filter

45 - Flow limiter

46 - Cold water inlet non-return valve

47 - 8 bar safety valve

48 - DHW recirculation pump (optional)

49 - Domestic hot water probe

50 - Magnesium anode

51 - Storage tank unit draining valve

RZ2 - Mixed zone 2 system return

MZ2 - Mixed zone 2 system flow

RZ1 - Direct zone 1 system return

MZ1 - Direct zone 1 system flow

G - Gas supply

AC - Domestic hot water outlet

AF - Domestic cold water inlet

RC - Domestic hot water recirculation

RP - Return from solar panels

MP - Flow from solar panels