8

MIX 120

Used oil is classified as special waste and must be

treated as such.

Dispose of old oil as

required by law.

Always ensure

that the protection

devices are undamaged

and efficient.

Check

the

condition of the power

cable before starting a

work session; it may

have

become

accidentally damaged.

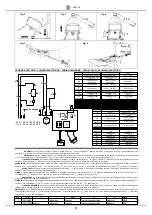

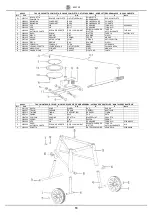

11.1 LIMIT SWITCH

ADJUSTMENT (Fig. 7)

The adjustment of the limit

switch must be carried out with the tank protection cover lowered.

Slacken screw

Ref. 1, line up the

mark on the cam

Ref. 2 with the

limit switch roller

Ref. 3 and tighten

screw Ref. 1. Use

Allen key N° 5.

11.2 OUTLET

PROTECTION

REMOVAL (Fig. 8)

Slacken screws Ref. 2 and remove protection Ref. 1. To replace the

protection, align the holes with those of brackets Ref. 3 and tighten

with screws Ref. 2. Use spanner N° 13.

11.3 MIXING PADDLE REPLACEMENT (Fig. 9)

Lift the drum protection cover Ref. 1.

Remove head protection Ref. 2, rotating it in an anti clockwise

direction. Slacken screws Ref. 3 and nuts Ref. 4. Use spanner

N°17.

Remove the paddle clamps Ref. 5, 6 and 7 and replace rubbers Ref.

8, 9 and 10, inserting them between holders Ref. 11, 12 and 13 and

clamps Ref. 5, 6 and 7. Utilize the slots in the rubbers to adjust as

necessary and fix with screws and nuts Ref. 3 and 4.

Push arm Ref. 14 to manually rotate the paddles, checking the mating

of the rubbers with the drum.

If there are zones where the rubber is not in contact with the tank, repeat the adjustment.

Re adjust at positions Ref. 15 and 16 if necessary. Replace and lock in position

protection Ref. 2, rotating it in a clockwise direction. Lower protection cover Ref. 1.

GB

12. TROUBLESHOOTING

WARNING!

All maintenance work must be carried out after the machine

has been stopped, placing the selector switch in the “0”

position and unplugging it.

PROBLEM

CAUSE

REMEDY

The motor does

not run when the

switch is moved to

the"1" position.

- No power in the

supply cable.

- The electric plug

and socket are not

connected properly.

- The cable from the

plug to the electric

panel is broken.

- A wire has

becone

disconnected

inside the panel.

- A wire has

become

disconnected on

the motor terminal

board.

- The switch is

faulty.

- A fuse has blown

inside the panel.

- The protection

cover is open.

- The limit switch is

faulty.

- The cam is

incorrectly

mounted.

- Check the cable.

- Make a proper

connection.

- Replace the cable

- Re make the

connection.

- Re make the

connection.

- Replace the

switch.

- Change the fuse

- Close it.

- Replace it

- Refer to limit

switch adjustment

"11.1".

The discharge

outlet leaks water.

- The sealing

gasket is worn.

- The spring is

broken or

ineffective.

- Replace the

rubber.

- Replace the

spring.

Scraper rubbers

do not mate with

the tank.

- Worn rubbers.

- Replace the

rubbers and/or

adjust their position

(see Mixing Paddle

Replacement

"11.3").

The outlet will not

open.

- Deposits in the

outlet protector.

- Remove and clean

the outlet protector

(see Outlet

Protection

Removal, "11.2").

Fig. 7

Fig. 8

Fig. 9