6

Optia HE

-

Installation & Servicing

GENERAL

INTRODUCTION

The Optia HE 9, 12, 15 and 18

are a range of automatically fully

controlled, wall mounted, balanced flue, fanned, high efficiency,

condensing gas boilers.

The primary heat exchanger is cast iron. The secondary heat

exchanger is aluminium. The boiler casing is of white enamelled

mild steel.

The boiler casing has a removable controls pod containing a drop-down

door. The boiler thermostat is located behind the drop-down door.

Note.

These boilers cannot be used on systems which include

gravity circulation.

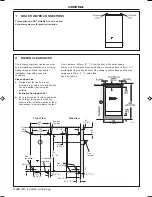

See Frame 1 for details of the correct boiler tappings to use.

The boilers are supplied with a standard flue kit suitable for rear

outlet from 114 mm (4

1/2

") to 705 mm (30

1/2

").

Side outlet applications require the optional extra side outlet kit.

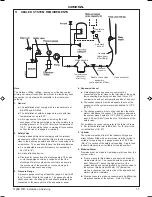

The boilers are suitable for connection to the following open

vented or sealed systems:

•

Fully pumped CH and indirect DHW

•

Pumped heating only.

•

Pumped indirect DHW only.

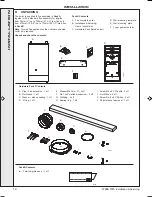

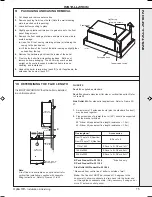

SAFE HANDLING

This boiler may require 2 operatives to move it to its installation

site, remove it from its packaging base and during movement

into its installation location. Manoeuvring the boiler may include

the use of a sack truck and involve lifting, pushing and pulling.

Caution should be exercised during these operations.

Operatives should be knowledgeable in handling techniques

when performing these tasks and the following precautions

should be considered:

•

Grip the boiler. Refer to Frame 18.

•

Split the boiler down to reduce the weight, e.g. remove casing

and hardware pack. Refer to Frame 9.

•

Be physically capable.

•

Use PPE as appropriate, e.g. gloves, safety footwear.

During all manoeuvres and handling actions, every attempt

should be made to ensure the following unless unavoidable

and/or the weight is light.

•

Keep back straight.

•

Avoid twisting at the waist.

•

Avoid upper body/top heavy bending.

•

Always grip with the palm of the hand.

•

Use designated hand holds.

•

Keep load as close to the body as possible.

•

Always use assistance if required.

OPTIONAL EXTRA KITS

FLUING:

z

Flue Extension Ducts.

(1000mm long) up to 3m

z

90

o

Elbow Kit

(60/100 dia maximum no. per installation)

up to 2 elbows

z

45

o

Elbow Kit

(60/100 dia maximum no. per installation)

up to 2 elbows

z

Side Outlet Kit

z

Vertical Connector Kit

z

Flue Finishing Kit

z

Roof Flue Kit

z

High Level Flue Outlet Kit

z

Flue Deflector Kit

OTHER OPTIONAL KITS:

z

Downward Piping Kit

z

Condensate Pump Kit

CURRENT GAS SAFETY (INSTALLATION AND USE)

REGULATIONS OR RULES IN FORCE.

The appliance is suitable only for installation in GB and IE and

should be installed in accordance with the rules in force.

In GB, the installation must be carried out by a CORGI

Registered Installer. It must be carried out in accordance with

the relevant requirements of the:

•

Gas Safety (Installation and Use) Regulations

•

The appropriate Building Regulations either The Building

Regulations, The Building Standards (Scotland), Building

Regulations (Northern Ireland).

•

The Water Fittings Regulations or Water byelaws in

Scotland.

•

The Current I.E.E. Wiring Regulations.

Where no specific instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a Competent

Person and installed in accordance with the current edition of

I.S.813 "Domestic Gas Installations", the current Building

Regulations and reference should be made to the current ETCI

rules for electrical installation.

Detailed recommendations are contained in the following British

Standard Codes of Practice:

BS.6891

Low pressure installation pipes.

BS.6798

Installation of gas fired hot water boilers of rated input

not exceeding 70 kW.

BS.5449

Forced circulation hot water systems.

BS.5546

Installation of gas hot water supplies for domestic

purposes (2nd Family Gases).

BS.7593

Treatment of water in domestic hot water central

heating systems.

BS.5440.1

Flues for gas appliances of rated input not exceeding

70 kW.

BS.5440.2

Ventilation for gas appliances of rated input not

exceeding 70 kW.

Health & Safety Document No. 635

The Electricity at Work Regulations, 1989.

Manufacturer’s notes must NOT be taken in any way as overriding

statutory obligations.

IMPORTANT.

These appliances are certificated by the British

Standards Institution for safety and performance. It is, therefore,

important that no external control devices, e.g. flue dampers,

economisers etc., are directly connected to these appliances -

unless covered by these Installation and Servicing instructions or

otherwise recommended by

Wolseley UK

in writing.

If in doubt please enquire.

Any direct reconnection of a control device not approved by

Wolseley UK

could invalidate the BSI Certification and the normal

appliance warranty. It could also infringe the Gas Safety Regulations

and the above regulations.

SAFE HANDLING OF SUBSTANCES

Care should be taken when handling the boiler insulation panels

which can cause irritation to the skin. No asbestos, mercury or

CFCs are included in any part of this boiler.

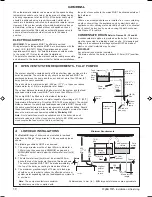

LOCATION OF BOILER

The boiler must be installed on a flat and vertical wall, capable of

adequately supporting the weight of the boiler and any ancillary

equipment.

The boiler may be fitted on a combustible wall and insulation

between the wall and the boiler is not necessary - unless required

by the local authority.

The boiler must not be fitted outside.

Timber Framed Buildings

If the boiler is to be fitted in a timber framed building it should be

fitted in accordance with the Institute of Gas Engineering document

IGE/UP/7:1998.

continued on page 8 . . . . . . . . .

201962-6.pmd

19/02/2008, 15:10

6

Содержание Optia HE 9

Страница 2: ...2 Optia HE Installation Servicing...