Optia HE -

Installation & Servicing

33

SERVICING

cla7851

2 casing

retaining

screws

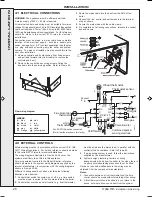

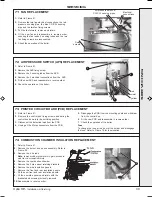

To ensure the continued safe and efficient operation of the

appliance it is recommended that it is checked at regular

intervals and serviced as necessary.

The frequency of servicing will depend upon the installation

condition and usage, but should be carried out at least

annually. It is the law that any service work must be carried out

by CORGI registered installer

.

In IE service work must be

carried out by a Competent Person.

1.

Light the boiler and carry out a pre-service check, noting

any operational faults. Operate the boiler for at least 20

minutes. Check the gas consumption.

2.

Connect a suitable gas analyser to the sampling point on

the top RHS of the back panel. For correct boiler operation

the CO/CO

2

content of the flue gas should not be greater

than 0.004 ratio. If this is the case and the gas input is at

least 90% of the nominal, then no further action need be

taken. If not, proceed to paragraph

3

.

3.

Clean the main burner. Refer to Frame 56.

4.

Clean the heat exchanger. Refer to Frame 55.

5.

Clean the main and pilot injectors. Refer to Frame 56.

6

Clean the recuperator. Refer to Frame 57.

1

3

2

4

cla9214

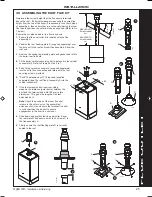

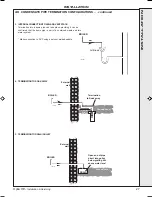

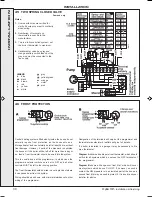

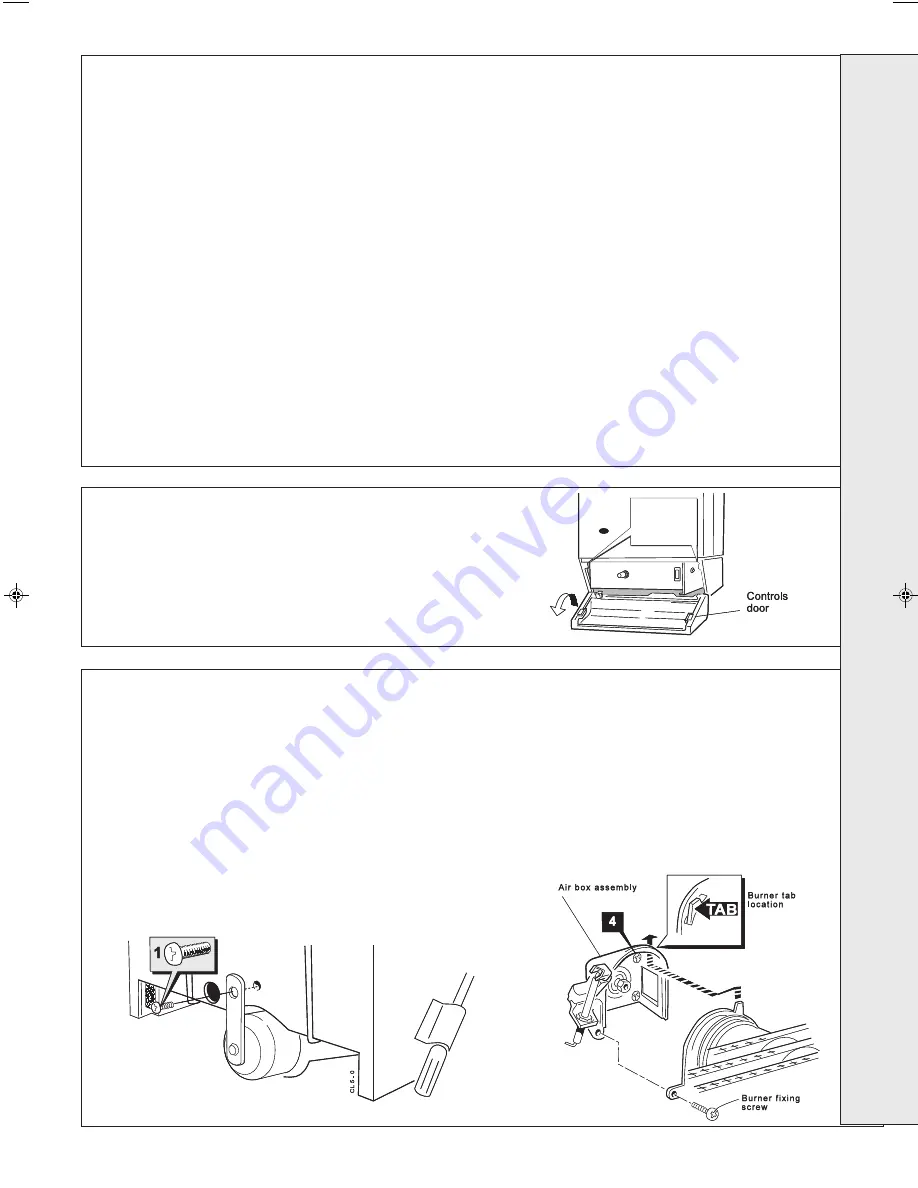

4.

Remove the 4 screws retaining the air box/pilot assembly

to the vertical manifold and carefully remove the assembly.

5.

On re-fitting the air box assembly, remove the old gasket

from the manifold and ensure the new gasket is located

correctly. Check that the joint is made gas tight. Ideal

Boilers recommend the air box fixing screws be replaced

with a torque of 4.0Nm in the number order shown on the

diagram below and be repeated to ensure even clamping.

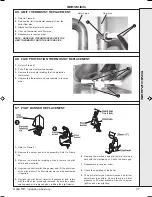

1.

Remove the screw retaining the front burner support

strap to the combustion chamber. Remove the M5 pozi

situated at the LH bottom rear of the burner and pull the

burner downwards to disengage the retention tab.

Remove the burner to a safe place for inspection and

cleaning.

2.

Remove the 2 control box fixing screws. Swing the box

downwards to disengage.

3.

Pull the HT lead connection off the printed circuit board

and pull the lead upwards through the bottom panel

grommet.

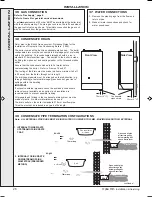

1.

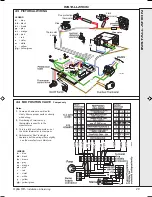

Open the controls pod door and release the 2 captive screws at

the bottom of the casing, then unhook the casing front panel

from the back panel and remove. Retain the front panel in a

safe place.

2.

Isolate the gas supply at the service cock fitted to the boiler.

53 BOILER FRONT PANEL REMOVAL

52 SERVICING SCHEDULE

7.

Remove and clean the siphon. Refer to Frame 58 and then

check the drain for blockage.

8.

Remove any debris from inside the base of the casing.

9.

Check that the flue terminal is unobstructed and that the

flue system is sealed correctly.

10.

If the appliance has been installed in a compartment, check

that the ventilation areas are clear.

The servicing procedures are covered more fully in Frames 54

to 60 and must be carried out in sequence.

WARNING.

Disconnect the electrical supply and turn off gas supply.

IMPORTANT.

After completing the servicing or exchange of

components always test for gas soundness and carry out

functional checks as appropriate. Refer to Frame 48, item 18

for gas adjustment sealing.

When work is complete the casing MUST be correctly refitted,

ensuring that a good seal is made.

T

he boiler must NOT be operated if the casing is not fitted.

11.

Complete the service section of the Benchmark

Commissioning Checklist.

54 BURNER AND AIR BOX REMOVAL

SER

VICING

201962-6.pmd

19/02/2008, 15:10

33

Содержание Optia HE 9

Страница 2: ...2 Optia HE Installation Servicing...