GWA

Gas-Fired Water Boilers –

Boiler Manual

11

Part Number 670 01 1001 00

Near-boiler piping

continued

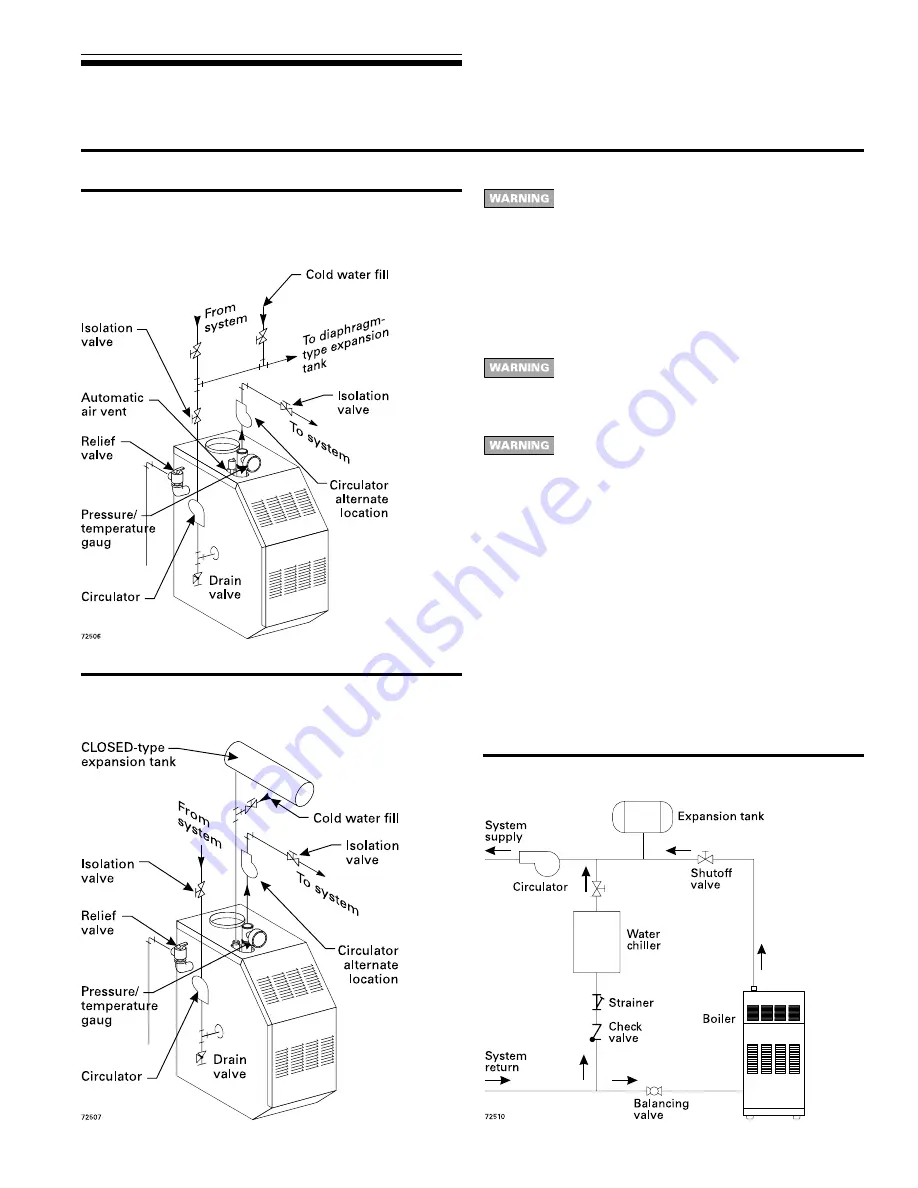

Figure 7

Piping refrigeration systems

Water piping — refrigeration systems

Prevent chilled water from entering boiler

Install boiler so that chilled medium is piped in parallel with the

heating boiler. Use appropriate valves to prevent chilled medium

from entering boiler. See Figure 7 for typical installation of balancing

valve and check valve.

If system includes radiant heating circuits, provide

piping and controls to regulate the temperature

supplying the radiant circuits. Failure to comply could

result in substantial property damage.

Use Figure 5 or Figure 6 only for systems designed

for return water at least 130 °F. For systems with low

return water temperature possible, such as

converted gravity systems and radiant heating

systems, install bypass piping (see page 12) to

protect boiler against condensation. Failure to prevent

low return water temperature to the boiler could cause

corrosion of the boiler sections or burners, resulting

in severe personal injury, death or substantial

property damage.

Install boiler so that chilled medium is piped in parallel

with heating boiler (Figure 7). Use appropriate valves

to prevent chilled medium from entering boiler. Consult

I=B=R Installation and Piping Guides.

If boiler is connected to heating coils located in air

handling units where they can be exposed to

refrigerated air, use flow control valves or other

automatic means to prevent gravity circulation during

cooling cycle. Circulation of cold water through the

boiler could result in damage to the heat exchanger,

causing possible severe personal injury, death or

substantial property damage.

Figure 6

Closed-type expansion tank: Piping to

single-zone system using closed-type

expansion tank. See Table 4 for piping sizes.

Figure 5

Diaphragm- or bladder-type expansion tank:

Piping to single-zone system using

diaphragm-type or bladder-type expansion

tank. See Table 4 for piping sizes.

3

Install water piping

continued

GWA

Gas-Fired Water Boilers –

Boiler Manual

26

Part Number 670 01 1001 00

10 Service and maintenance

continued

❏

❏

❏

❏

❏

Check/test. . . . . . . . . .

continued

Diaphragm- or bladder-type — welded gas tight with a rubber

membrane to separate the tank pressurizing air and the water.

May be located at any point in the system, but most often found

near the boiler.

•

Systems with this type of expansion tank require at least

one automatic air vent, preferably located on top of an air

eliminator, as shown in examples in Manual Section 3,

page 10.

2. If relief valve has tended to weep frequently, the expansion tank

may be waterlogged or undersized.

Closed-type tank — tank is most likely waterlogged. Install a

tank fitting if not already installed. Then check fill level per fitting

manufacturer’s instructions. If fill level is correct, check tank

size against manufacturer’s instructions. Replace with a larger

tank if necessary.

Diaphragm- or bladder-type — first, check tank size to be

sure it is large enough for the system. If size is too small, add

additional tank(s) as necessary to provide sufficient expansion.

If tank size is large enough, remove tank from system and

check charge pressure (usually 12 psig for residential

applications). If tank won’t hold pressure, membrane has been

damaged. Replace tank.

Boiler relief valve

1. Inspect the relief valve and lift the lever to verify flow as in the

following warnings, excerpted from a relief valve manufacturer’s

warning label. Before operating any relief valve, ensure that it is

piped with its discharge in a safe area to avoid severe scald

potential. Read Manual Section 3, page 10, before proceeding

further.

2. After following the preceding warning directions, if the relief valve

weeps or will not seat properly, replace the relief valve. Ensure

that the reason for relief valve weeping is the valve and not

over-pressurization of the system due to expansion tank

waterlogging or undersizing.

❏

❏

❏

❏

❏

Review with owner

1. Review the User’s Information Manual with the owner.

2. Emphasize the need to perform the maintenance schedule

specified in the User’s Information Manual (and in this manual

as well).

3. Remind the owner of the need to call in a licensed contractor

should the boiler or system exhibit any unusual behavior.

4. Remind the owner to follow the proper shutdown procedure

and to schedule an annual start-up at the beginning of the next

heating season.

The boiler contains ceramic fiber and fiberglass

materials. Use care when handling these materials

per instructions on page 23 of this manual. Failure to

comply could result in severe personal injury.

1. Shut down boiler:

•

Follow “To Turn Off Gas to Appliance” instructions on boiler

and “Lighting or Operating Instructions”.

•

Do not drain boiler unless it will be exposed to freezing

temperatures. If using antifreeze in system, do not drain.

2. Follow shutdown procedure.

3. Remove venting system connection to boiler.

4. Remove top jacket panel. Turn back insulation.

5. Remove flue collector. Clean sealant from assembly and

sections.

6. Remove radiation plates hanging between sections.

7. Remove burners from base. Brush and vacuum burners to

remove all dust and lint. Verify that all burner ports are free of

debris.

8. Place newspapers in base of boiler to collect soot.

9. Clean between sections with wire flue brush.

10. Remove newspaper and soot. Vacuum or brush base and

surrounding area.

11. Reinstall radiation plates.

12. Replace collector box/transition assembly. Seal with sealant.

Obtain gas-tight seal to prevent flue gas spillage and carbon

monoxide emissions, resulting in severe personal injury or death.

13. Replace insulation and jacket top panel.

14. Start up boiler following section 6, pages 15–17 of this manual

and the boiler “Lighting Instructions”, pages 20 and 21.

Excessive sooting indicates improper gas combustion. If found,

check for proper combustion and make any necessary

adjustments.

❏

❏

❏

❏

❏

Cleaning boiler heating surfaces

Safety relief valves should be reinspected AT LEAST

ONCE EVERY THREE YEARS, by a licensed plumb-

ing contractor or authorized inspection agency, to

ensure that the product has not been affected by

corrosive water conditions and to ensure that the

valve and discharge line have not been altered or

tampered with illegally. Certain naturally occurring

conditions may corrode the valve or its components

over time, rendering the valve inoperative. Such con-

ditions are not detectable unless the valve and its

components are physically removed and inspected.

This inspection must only be conducted by a plumb-

ing contractor or authorized inspection agency — not

by the owner. Failure to reinspect the boiler relief valve

as directed could result in unsafe pressure buildup,

which can result in severe personal injury, death or

substantial property damage.

Following installation, the valve lever must be oper-

ated AT LEAST ONCE A YEAR to ensure that wa-

terways are clear. Certain naturally occurring min-

eral deposits may adhere to the valve, rendering it

inoperative. When manually operating the lever, wa-

ter will discharge and precautions must be taken to

avoid contact with hot water and to avoid water dam-

age. Before operating lever, check to see that a dis-

charge line is connected to this valve directing the

flow of hot water from the valve to a proper place of

disposal otherwise severe personal injury may re-

sult. If no water flows, valve is inoperative. Shut down

boiler until a new relief valve has been installed.

Содержание GWA 245

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 8: ......

Страница 10: ......

Страница 12: ......

Страница 14: ......

Страница 16: ......

Страница 18: ......

Страница 20: ......

Страница 22: ......

Страница 24: ......

Страница 26: ......

Страница 28: ......

Страница 30: ......

Страница 32: ......

Страница 34: ......

Страница 36: ......