1-21

INSTALLATION

HC SERIES BOILERS

HC 13-50, HC 23-84, HC 29-106, HC 33-124, HC 20-125, HC 33-160

Do not place any water connections overhead the boiler;

leaks can damage

the fan and controls. If needed, create a shield over the top of the cover, but

allow clearance for airflow and service access.

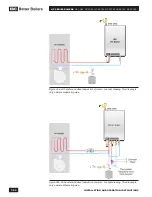

For best results, use a

Primary: Secondary

piping system, with a boiler loop

using 1" (1-1/4" for the HC 33-160) piping for the HC Series Boilers. The boiler

comes with the boiler (primary) pump installed in the boiler and will provide

adequate flow for the boiler and primary loop piping only.

The minimum flow rate required through the heat exchanger is 2 USgpm with a

maximum of 11 USgpm allowed. Primary/Secondary piping ensures adequate

flow and de-couples Δ°T issues (boiler vs. distribution). Aim for a 20° to 30° F Δ°T

across the heat exchanger at high fire.

The HC Series modulating boilers are designed to supply the heating load with

temperatures within the range of 86°F to 194°F. Use closely spaced tee’s to

connect each pumped space heating load to the primary loop. As an option, a

hydraulic separator or buffer tank can be used to separate the heating loads from

the boiler.

Always ensure that loads sensitive to high temperatures are protected using

means such as a mixing valve set for maximum limit (say 130°F) to protect

radiant floors, or an aquastat (wired to the boiler’s Heat Demand X4.6 and X4.7

terminals).

Ensure the pump is rated for the design circulating water temperatures; some

pumps have a minimum water temperature rating above the low temperature

potential of the boiler. Following installation, confirm actual performance by

measuring Δ°T (under high and low flow conditions) after establishing the correct

firing rate

.

A variety of application drawings showing basic design options are available from

the IBC web site at

www.ibcboiler.com

Figure 24: Boiler trim basic options – concept drawing. This drawing is only a simple

schematic guide.

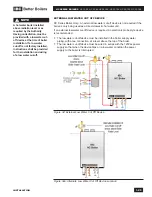

WARNING

Close fill valve after any

addition of water to the

system, to reduce risk of

water escapement.

NOTE

Application drawings can be

downloaded from our web site.

www.ibcboiler.com

NOTE

The boiler, when used

in connection with a

refrigeration system,

must be installed so the

chilled medium is piped in

parallel with the boiler with

appropriate valves to prevent

the chilled medium from

entering the boiler.

NOTE

The boiler piping system of

a hot water boiler connected

to heating coils located in

air handling units where

they may be exposed to

refrigerated air circulation

must be equipped with

flow control valves or other

automatic means to prevent

gravity circulation of the

boiler water during the

cooling cycle.

WARNING

Ensure the gas ignition

system components are

protected from water (dripping,

spraying, rain, etc.) during

appliance operation and when

servicing (pump replacement,

condensate trap servicing,

control replacement, etc.)

Содержание HC 33-124

Страница 76: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Страница 77: ...NOTES...