• Trouble Shooting Model E24

The following charts list possible problems that may occur in the operation of an E24 conveyor.

TROUBLE SHOOTING DRIVES

TROUBLE

CAUSE

SOLUTION

No motors on the conveyor will run.

1) No AC power to the power supply unit.

2) Main power disconnect on the power supply unit is “off.”

3) Main fuses blown.

4) No lights on motor/control board.

5) Board not receiving run signal

1) Check AC power.

2) Set disconnect to “on.”

3) Replace fuses.

4) Check output power of power supply.

5) Check connections and insure run signal is active

Individual zone will not run.

1) Motor/Control Board power pins not connected to wiring harness.

2) Motor power connector not connected to Control Board. (E24™ motor

only.)

3) Blown fuse indicator “ON”. (E24i™)

4) Defective control board.

5) Defective motor.

1) Connect wiring harness and pin connector to power pins

on Motor/Control Board.

2) Connect motor power connector to Motor Control Board.

3) Replace motor.

4) Replace fuse.

5) Replace control board.

zone will not restart after accumulation. 1) O-ring band(s) stretched or worn.

1) Replace o-ring(s).

• Trouble Shooting Model E24EZ

The following charts list possible problems that may occur in the operation of an E24Ez conveyor.

TROUBLE SHOOTING DRIVES

TROUBLE

CAUSE

SOLUTION

No zones on the conveyor

will run.

1) No AC power to the power supply unit.

2) Main power disconnect on the power supply unit is “off.”

3) Main fuses blown.

4) No lights on Motor/Control Board.

5) No power to EzLogic® zone Controller

1) Check AC power.

2) Set disconnect to “on.”

3) Replace fuses.

4) Check output power of power supply.

5) Check EzLogic® connections and IOP.

Individual zone will not run.

1) Motor/control board power pins not connected to wiring harness.

2) EzLogic® zone controller output cable not connected to motor/control board.

3) Motor power connector not connected to control board. (E24 motor only.)

4) zone controller lens is dirty.

5) Reflector missing or damaged.

6) Defective EzLogic® zone controller.

7) Blown fuse indicator “ON”.

8) Blown fuse indicator “ON”. (E24™)

9) Defective control board.

10) Defective motor.

1) Connect wiring harness and pin connector to power pins

on Control Board.

2) Connect cables.

3) Connect motor power connector to motor control board.

4) Clean lens.

5) Replace reflector.

6) Replace EzLogic® zone controller.

7) Replace motor.

8) Replace fuse.

9) Replace control board.

10)Replace motor.

zone will not restart after

accumulation.

1) zone controller lens is dirty.

2) O-ring band(s) stretched or worn.

1) Clean lens.

2) Replace o-ring(s).

zone will not “sleep.”

1) Sleep feature disabled.

2) Upstream zone is blocked.

1) Enable sleep feature.

2) Unblock upstream zone.

Product will not accumulate

from the discharge zone back.

1) No zone stop signal to discharge zone.

1) Check input cable and signal source.

occurs when the motor load current requirement exceeds the selected

maximum current value. When the current requirement drops below this

value, the indicator will turn off.

Fault Indicator LED (Red)

This LED indicates information about various faults, either by flashing or by

remaining in a steady “ON” state. Flash patterns are repeated at four-second

intervals. The indicated faults are as follows:

One flash - Board hardware problem

•

Two flashes - Over-Voltage

•

Three flashes - Under-Voltage

•

Four flashes - Internal motor fault

•

Five flashes - Control Board over temperature shut down

•

Six flashes - Extreme over current shut down

•

On steady - Stalled motor

•

Blown Fuse Indicator LED (Red)

This LED will be illuminated if the replacement fuse is blown.

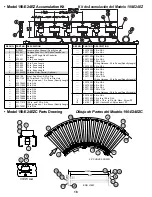

Motor Connector

This connector accepts the connector on the E24™ motor’s cable. The

connection provides power to the motor and allows the control board to

monitor the motor’s load status. Note: See Figure 14B for correct orientation.

Speed Control Potentiometer

The speed control potentiometer is used to vary the speed of an individual

E24™ motor. Speed-up and slow-down areas may be created to gap product,

provide more accurate positioning, etc.

Setup Selection Switches

There are four dipswitches on the control board that are used to configure the

board for specific applications. The switches are numbered 1 through 4, with

1 being the top switch when viewing the control board as shown in the figure.

They are read only at power-up, meaning that any changes to switches will

not take effect until the power is cycled to the E24™ system. The functions of

the switches are as follows:

Switch 1 - Motor Rotation Selector Switch

This switch determines the default or “forward” direction of rotation of the

E24™ motor. When the switch is in the “ON” (right) position the motor rotates

clockwise when viewed from the back of the motor. When the switch is in the

“OFF” (left) position the motor rotates counter-clockwise when viewed from

the back of the motor.

Switch 2 - Input Type Selector Switch

This switch is used to set the type of input accepted by the “motor-run” input

terminal and the “motor direction” input terminal. It does NOT affect the

EzLogic® controller connector input. When the switch is in the “OFF” (left)

position the inputs are “NPN” type; that is , an input is activated by connecting

the terminal to DC(-) terminal using a jumper wire or through a switch. When

the switch is in the “ON” (right) position the inputs are “PNP” type; that is, an

input is activated by connecting the terminal to the +24VDC terminal using a

jumper wire or through a switch. PNP is recommended.

Switch 3 - Dynamic Braking Enable Switch

This switch is used to enable the dynamic braking feature. When the switch

is in the “OFF” (left) position the dynamic braking feature acts to stop motor

rotation quickly when the motor is turned off. When the switch is in the “ON”

(right) position the motor will coast to a stop when it is turned off.

Switch 4 - Current Limit Selector Switch

This switch selects the maximum current that the control board will allow the

E24™ motor to use. When the switch is in the “OFF” (left) position the current

limit is set at 1.5 amps. When the switch is in the “ON” (right) position the

current limit is set at 3.0 amps. For most applications the switch should be

set to the “OFF” position to prevent drawing too much current from the motor

power supply.

15