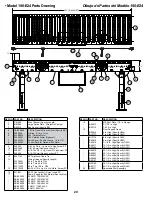

• Racked Sections

It is important that each bed section be checked for an out-of-square

condition. If conveyor is not square, tracking problems will result. Figure 5A

indicates a racked section.

TO CORRECT AN OUT-OF-SQUARE SECTION

1. Locate points on corners of section and measure distance “A” & “B”. If the

dimensions are not equal, the section will need to be squared. (Figure 5B).

2. Use crossbracing supplied on underside of conveyor to square each

section. Adjust turnbuckle until Dimensions “A” & “B” are equal.

3. After all bed sections have been checked and corrected for “racked

condition”, tighten all butt couplings and pivot plate bolts.

4. Make final check to see that all conveyor sections are level

across width and length. If entire conveyor is level, supports

can be lagged to floor.

“Racked” conveyor sections will cause package to travel

toward side of conveyor.

OPERATION

• Conveyor Start-Up

Before conveyor is turned on, check for foreign objects that

may have been left inside conveyor during installation. These

objects could cause serious damage during start-up.

After conveyor has been turned on and is operating, check all moving parts to

make sure they are working freely.

• Lubrication

BEARINGS

STANDARD: Supplied sealed and pre-lubricated. No Lubrication required.

• Sequence of Operation

EZLOGIC® EQUIPPED VERSIONS

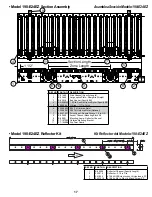

The Model 190-E24Ez is made up of a series of accumulation zones, each zone

having an EzLogic® zone Controller, a E24™ motor to drive the zone, idler rollers

driven from the E24™ motor with o-rings, and a motor control board that controls

and protects the E24™ motor.

The EzLogic Accumulation System provides two modes of accumulation which are

user-selectable: Singulation mode and Slug mode. The sequences of “loading” and

“unloading” the conveyor in the two modes are as follows:

LOADING THE CONVEYOR - SINGULATION MODE

1. Beginning with the conveyor empty, and the zone stop signal to the discharge

controller “active”, a carton placed on the conveyor continues forward until it

reaches the discharge zone (zone #1).

2. If two or more cartons are placed on the conveyor with a space of less than one

zone length between them, the cartons will singulate (separate) during the first few

feet of travel on the conveyor, until a space approximately equal to one zone length

exists between all cartons.

3. When carton #1 activates controller “A”, zone #1 stops driving. A signal is sent

to zone #2 indicating that zone #1 is occupied (Figure 5C).

4. When carton #2 activates controller “B”, zone #2 stops driving. A signal is sent to

zone #3 indicating that zone #2 is occupied.

5. The above sequences are repeated until the conveyor is fully loaded.

UNLOADING THE CONVEYOR-SINGULATION MODE

1. Releasing carton #1 is accomplished by “de-activating” the zone stop signal to

the discharge zone (Refer to the “Auxiliary Connections” section on pages 6 and

7). This restores power to the tread rollers in zone #1. Carton #1 will then move

forward, causing a gap between itself and carton #2 (Figure 5D).

2. When carton #1 clears controller “A”, carton #2 will then move forward, creating

a gap between itself and carton #3.

3. This sequence will continue as long as the preceeding carton continues to move

forward.

LOADING THE CONVEYOR-SLUG MODE

1.Beginning with the conveyor “empty,” and the zone stop signal to the discharge

controller “active,” a carton placed on the conveyor continues forward until it

reaches the discharge zone (zone #1).

2.If two or more cartons are placed on the conveyor with a space of less than one

zone length between them, the cartons will not singulate (separate) while traveling

down the conveyor.

3. When carton #1 activates controller “A”, zone #1 stops driving. A signal is sent

to zone #2 indicating that zone #1 is occupied.

4. When carton #2 activates controller “B”, zone #2 stops driving. A signal is sent to

zone #3 indicating that zone #2 is occupied.

5. The above sequences are repeated until the conveyor is fully loaded.

UNLOADING THE CONVEYOR-SLUG MODE

1. Releasing all cartons is accomplished by “de-activating” the zone stop signal to

the discharge zone (Refer to the “Auxiliary Connections” section). This causes all

occupied zones to drive and restores power to the tread rollers. All cartons then

move forward (Figure 5D).

2. All cartons will continue to move forward without singulation as long as the zone

stop signal is de-activated.

JAM PROTECTION - SLUG MODE ONLY

This feature, when enabled, helps prevent product pile-up and/or damage if a

carton should become jammed on the conveyor. The sequence of operation when

a jam occurs is as follows:

If a carton becomes jammed at any point along the conveyor for a period of 6

seconds or longer, cartons on the upstream side of the jammed carton will stop in

sequence until the jammed carton is dislodged or removed. The zone containing

the jammed carton will continue to drive, in many cases dislodging the jammed

carton without additional help. The accumulated zones will return to normal once

the jam is cleared.

"

A

"

"

B

"

SIDE CHANNEL

(CANAL LATERAL)

(LONG ROD)

CROSSBRACING

([VARILLA LARGA]

TIRANTE TENSOR)

FRAME SPACER

(ESPACIADOR

DE CAMA)

(SHORT ROD)

(VARILLA CORTA)

TURNBUCKLE

(TENSOR)

SIDE CHANNEL

(CANAL LATERAL)

FIGURE 5B

SIDE CHANNEL

(CANAL LATERAL)

ROLLERS NOT

SQUARE WITH

SIDE CHANNELS

(RODILLOS

DESCUADRADOS

CON CANALES

LATERALES)

FIGURE 5A

IMPORTANT! Being out of level across this width of conveyor

can cause package drift on long conveyor lines.

CAUTION!

Because of the many moving parts on the conveyor, all personnel in the

area of the conveyor need to be warned that the conveyor is about to be started.

CONTROLLER "C"

(CONTROLADOR "C")

CONTROLLER "B"

(CONTROLADOR "B")

CONTROLLER "A"

(CONTROLADOR "A")

ZONE #3

CARTON

#3

CARTON

#2

CARTON

#1

(ZONA)

ZONE #2

(ZONA)

(FLUJO)

ZONE #1

(ZONA)

FLOW

FIGURE 5C

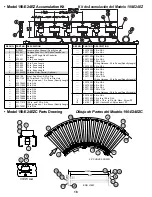

GAP UNCHANGED

(ESPACIO SIN CAMBIO)

GAP UNCHANGED

(ESPACIO SIN CAMBIO)

FLOW

CARTON

#3

CARTON

#2

CARTON

#1

(FLUJO)

CONTROLLER "C"

(CONTROLADOR "C")

CONTROLLER "B"

(CONTROLADOR "B")

CONTROLLER "A"

(CONTROLADOR "A")

FIGURE 5D

5