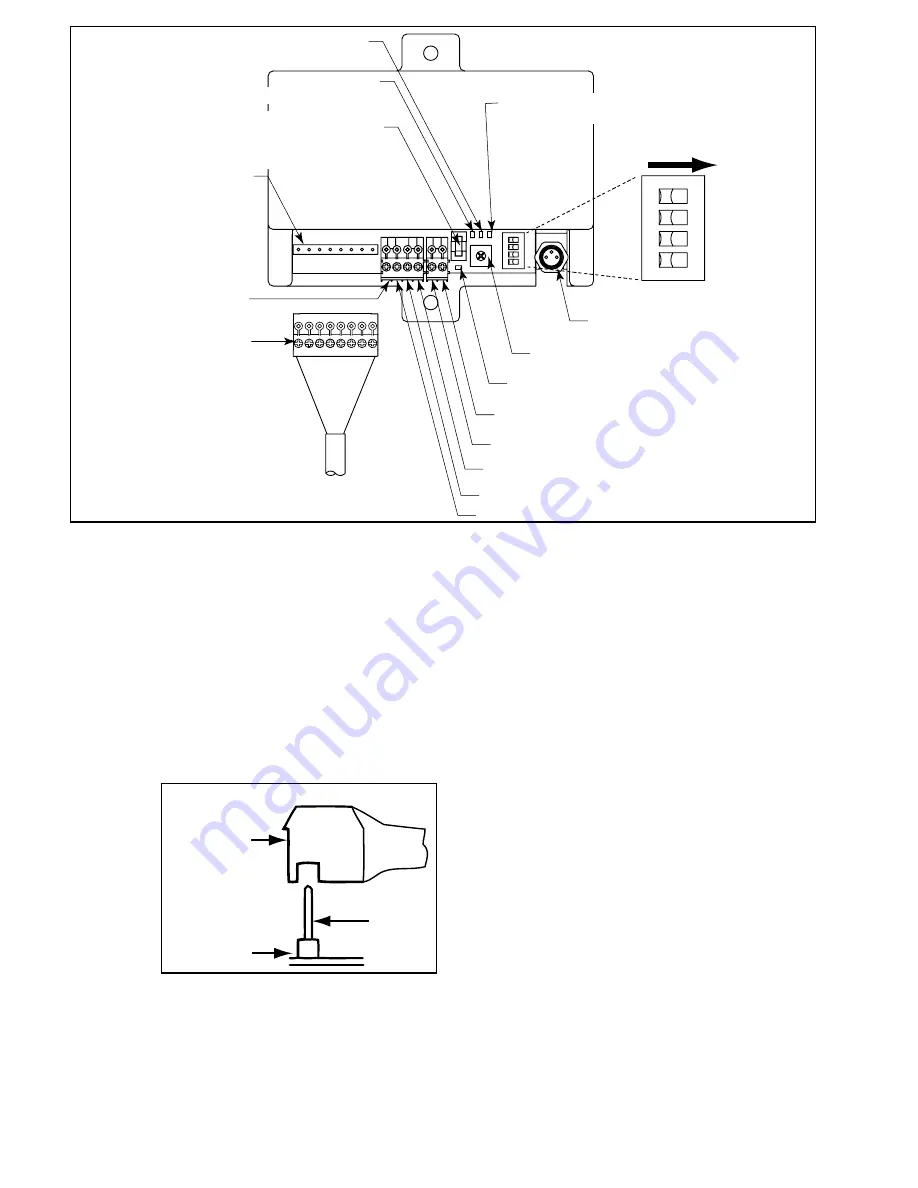

EZLOGIC® CONTROLLER CONNECTOR

(CONECTOR DEL CONTROLADOR EZLOGIC)

SPEED CONTROL POTENTIOMETER

(CONTROLADOR DE VELOCIDAD)

RED L.E.D. (BLOWN FUSE INDICATOR

)

(INDICADOR LED ROJO (INDICADOR DE FUSIBLE FUNDIDO)

DC (-)

(CORRIENTE DIRECTA DC (-)

+24V DC INPUT

(ENTRADA DE CORRIENTE D24V DC)

MOTOR RUNNING OUTPUT

(SALIDA DE MOTOR EN FUNCIONAMIENTO)

ANALOG SPEED INPUT

(SALIDA DE VELOCIDAD ANALÓGICA)

MOTOR DIRECTION

(DIRECCION DEL MOTOR)

MOTOR RUN

(ARRANQUE DEL MOTOR)

MOTOR CABLE

(CABLE DEL MOTOR)

MOTOR CONNNECTOR

(CONECTOR DEL MOTOR)

REPLACEABLE FUSE

(LITTEL FUSE 0454005 OR EQUIVALENT)

[(FUSIBLE REEMPLAZABLE (FUSIBLE LITTLE

0454005 O EQUIVALENTE)]

RED L.E.D. (FAULT)

[INDICADOR LED ROJO (FALLA)]

AMBER L.E.D. (INIDCATES CURRENT LIMITING)

[INDICADOR LED NARANJA (INDICA CORRIENTE LIMITADA)]

GREEN L.E.D.

(POWER CONNECTED)

INDICADOR LED VERDE (POTENCIA CONECTADA)

SW1

SW2

SW3

SW4

ON

(PRENDIDO)

FIGURE 14A

• The Motor Control Board

The motor control board is an integral part of the E24™ system. The control

board performs the following functions:

1. Provides power to the motor.

2. Allows the motor to be operated by an EzLogic® zone controller or other

control device.

3. Limits the current to the motor to protect the motor from damage in the case

of an overload or stall condition.

4. Provides optional dynamic braking.

5. Allows the default direction of rotation to be selected.

6. Provides speed control for the motor.

7. Provides LED’s to indicate when the board is receiving power and when

certain fault conditions occur.

The parts of the motor control board are shown in Figure 14A. Each of these

parts and their function are described below.

Plug the motor connec-

tor into the 8-pin header

(item 1) on the board,

oriented as shown in

Figure 14B: Orientation

of Motor Connector and

Plug. The notch in the

bottom of the plug fits

securely over the black

bar on the pin header.

NOTE: Incorrect as-

sembly of the motor

plug to the control

card will result in a

damaged motor and card.

+24VDC Input, DC (-) Terminals

These terminals provide power to the control board and motor. The two pin

connector from the wiring harness supplies power to this location.

Replaceable Fuse

The replaceable fuse protects the motor and control board from damage

due to electrical shorts and overloads. Replacements must be 5A slow blow

Littelfuse #0454005 or equivalent.

EZLogic® Controller Connector

This connector accepts a drive/no drive signal from an EzLogic® zone

controller (when used). The connector is a male 8mm push-type connector

that mates with the female connector of the EzLogic® zone controller. When

the control board receives a “run” signal from the EzLogic® zone controller,

it turns on the E24™ motor.

Motor Run Terminal

This terminal is used to provide a “run” signal to the motor control board

when EzLogic® is not being used, such as on the 190-E24 conveyor. The

type of signal used may be NPN type or PNP type and is determined by the

position of the input type selector switch (switch 2). For the 190-E24 conveyor

the switch is set to PNP mode. This means that each time this terminal is

connected to 24DC(+), or ground the motor will run.

Motor Direction Terminal

This terminal is used to provide a “reverse” signal to the motor control board.

The type of signal used may be NPN type or PNP type and is determined by

the position of the input type selector switch (switch 2). The actual definition

of “forward” and “reverse” is determined by the position of the motor rotation

selector switch (switch 1). This input is not used on standard configurations of

the E24™ family of conveyors, but may be used in special applications.

Analog Speed Input

This terminal is used to send an analog speed input to the motor control

boards. The signal may range from 0 to 10 VDC. As the input voltage

increases, the speed of the motor will increase in 16 increments. If the signal

is not present or drops below 1 VDC, the board reverts back to the on board

speed potentiometer. Maximum speed is acquired at or above 9 VDC.

Motor Running Output Terminal

This terminal is used to provide a “motor running” signal from the motor control

board. The output is a PNP type output and is active as long as the motor

controlled by the control board is running. This output is not used on standard

configurations of the E24™ family of conveyors, but may be used in special

applications, such as when two E24™ motors are required in one conveyor

zone to handle heavier loads. Input and output can be set independently of

signal from EzLogic® module.

Power Indicator LED (Green)

This LED will be illuminated at all times if input power is connected to the

controller with the proper polarity.

Current Limiting Indicator LED (Amber)

This LED will be illuminated if the board is in current limiting mode. This

8-PIN MOTOR

CONNECTOR

(8-PIN MOTOR

CONNECTOR)

CABLE

CONNECTOR

PLUG

(CABLE

CONECTOR

ENCHUFE)

ITEM 1

FIGURE 14B

14