Commissioning

HYDAC Filtertechnik GmbH

en

Page 45

BEWA OLF15-60 10bar 3255361-01a en.doc

2005-11-22

9

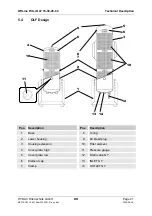

Suction Port Connection

The suction port may be connected to a flexible hi-collapse hose, or to hard piping. If the

OLF is connected to hard piping, precautions must be taken to ensure that no stresses or

vibrations are transmitted to the pump/filter housing. Dampeners may have to be installed.

Constrictions in the connections and lines should be avoided in order to prevent

compromising suction output (

⇒

danger of cavitation).

The nominal size of the connected hoses/piping must be at least as large as

the inlet/outlet port sizes of the pump.

If large contaminant particles are present (

>

100 µm), e.g. weld spatter, an

appropriate strainer must be installed in the suction line to protect the pump.

If the unit is installed below the fluid level of the reservoir, a shut-off must be

installed in order to allow filter element replacement. If a unit without a

pump/motor group is used, it is important to ensure that no pressure

pulsation is transmitted to the unit.

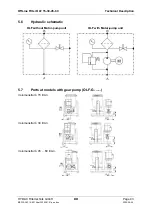

10

Pressure Port Connection

The nominal size of the pressure hose should be equal to that of the filter housing port

whenever possible. If a smaller hose size is used, the pressure drop must nevertheless be

less than 2 bar (29 psi) with a clean filter element

Make sure that no vibrations or stress/loading from other machinery and equipment are

carried over to the pump or filter housing. Use hoses and expansion joints as may be

necessary.

Make sure to also install the return-flow line or return-flow hose below the oil level in order to

prevent air from entering the fluid.

For back pressures of >1 bar (14.5 psi), a differential clogging indicator

should be installed.