3. Connect the pressure tester to the fuel inlet on the

carburetor. Increase the pressure to 50kPa. Refer to

Servicing tools on page 8.

4. Lower the carburetor in a container with gasoline to

find leaks.

5. Make sure that there is no leaks.

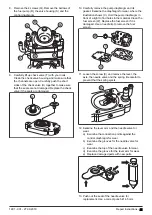

7.7.7 To clean and examine the carburetor

1. Clean the needle valve.

2. Examine the lever arm and the needle valve.

Replace damaged parts.

3. Examine the fuel hole of the needle jet and the main

nozzle.

4. Examine the metering chamber. If there is dirt in the

metering chamber, blow with compressed air and

then clean with clean oil.

5. Measure the height (A) of the lever arm and adjust

the height if it is necessary. Correct height is

4±0.5mm.

A

6. Examine the distance piece for damage. Replace

the distance piece if it is damaged.

7. Examine the remaining parts. Replace damaged

parts.

7.7.8 To adjust the idle speed

The idle speed is adjusted at the factory before the

product is supplied. An adjustment of the idle speed can

become necessary because of changes in the operation

conditions, for example, in the air.

WARNING: If the cutting attachment does not

stop when you adjust the idle speed, speak to

your servicing dealer. Do not use the product

until it is correctly adjusted or repaired.

•

Make sure that the throttle wire is parallel with the

flexible shaft. If the throttle wire is twisted, make the

throttle wire straight.

•

If the shaft is bent, the play of the wire is changed.

Make the shaft straight and put the product in the

position you usually operate it before you adjust the

idle speed.

•

The idle speed is correct when the engine operates

smoothly in all positions. The correct idle speed is

set when the product does not stop and the cutting

equipment does not rotate.

1. Start the engine and operate the product at half

speed for >2 minutes until the engine becomes

warm.

2. Turn the idle adjustment screw clockwise until the

cutting attachment starts to rotate.

1291 - 001 - 27.09.2019

Repair instructions - 23

Содержание 333RB Mark II

Страница 1: ...Workshop manual 333RB Mark II English 1291 001 27 09 2019 ...

Страница 47: ...1291 001 27 09 2019 Technical data 47 ...

Страница 48: ...1141571 26 2019 09 30 ...