37

[Gas leakage detector mode]

: Gas leakage detector mode is designed to stop combustion by built in sensor in controller in case of gas leakage. In

case of gas leakage, room temperature controller power is off and after one min, gas leakage is detective more than 10

min or 3 times in 10 min, the error is locked until manually on/off from the room controller.

With either front display panel or room controller off, fan stops after post-purge and still detects gas leakage 5 seconds.

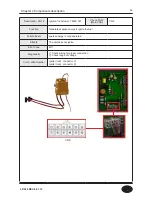

[Front panel and room controller connect mode]

: Room controller and front panel can be connected

[Heating demand connect mode]

: Outside heating demand can be connected

[Mixing valve default mode]

: If there is no DHW demand, mix valve stands by 800 steps, if still no operation of mixing valve is detected, to prevent

mixing valve stuck, 2,000 steps (close way) for 5 sec and default (open way) and back to 800 step.

[Mixing valve operation]

: If there is DHW demand, mixing valve modulates to set DHW temperature and water outlet temperature.

When demand is off, with the waiting mode, it goes back to 800 steps and after 2 minutes waiting mode, stays at 800

steps.

If controller is off, it closes at max step.

[Pump operating mode]

: In case pump 1 and 2 is not detected operation, it automatically runs for 90 seconds.

[Summer mode]

: Summer mode can be set with front panel, if used, no heating mode can be operated.

[Pre-heating mode]

: DHW pre-heating mode can be set with front panel, no heating mode can be operated.

[Heating burner operation delay mode]

: To prevent from quick burner ON/OFF, even if the temperature is reached, after anti-frequency time, burner is on. The

time set is between 0~20 and default is 1 minute.

[Memory mode]

: Desired condition and error can be set with front display panel. And the setting is memorized after power off or breakout.

[Safety function]

1. Power supply

After power is supplied for 5 sec, boiler monitors in real time if power and Hz are safe range.

1-1. Low power supply

If power supply is below 93Vac(+-3V) for 10 sec, boiler stops combustion until power supply is 95Vac(+-3V).

1-2. Frequency error

With power supplied, boiler chooses either 50Hz or 60Hz and if frequency reaches out of the range (±5Hz) for

more than 10 sec, combustion stops until frequency is within ±5Hz

[Combustion safety]

After combustion, in case there is no flame detected or malfunction of sensor, stops combustion automatically. With

stopped combustion, fan modulates second step and operates with first speed for 1 min and another 1 min with second

speed.

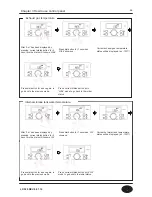

1. No flame detected

In case no flame is detected, it tries flaming as shown 13.4, if still no flame is detected after 10th trial, stops combus

-

tion and locked until ON/OFF from the front display panel. After re-flaming, if normal flame is detected, accumulated

error is defaulted.

2. No flame detected during combustion

In case no flame detected after normal flame within 1 min, retrial as shown 13.3, but fails 8 times, stops and combus

-

tion and locked until ON/OFF from the front display panel. After re-flaming, if normal flame is detected, accumulated

error is defaulted.

3. Flame detected before combustion

In case flame is detected before combustion, stops combustion due to unidentified flame detected error..

4. Flame detected after combustion stopped

No flame detector is operated for 2 min (Post-Purge time) after combustion

5. Safety function for un-normal fan operation

It checks fan operating condition before combustion. If it operates 100RPM for 5 sec, stops combustion and error

conde will be displayed..

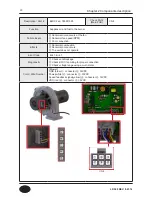

Chapter 3 How to use control panel

LP-528 REV. 8.01.14

Customized Temperature Control

Advanced technology used for the flow sensor and heat capacity control makes domestic hot water highly efficient by

maintaining constant temperature during usage.

■ Control panel

Содержание EFTC-140F

Страница 3: ...1 LP 528 REV 8 01 14 ...

Страница 11: ...9 Domestic Hot Water Mode Space Heating Mode Flow chart Chapter 1 Product Characteristics LP 528 REV 8 01 14 ...

Страница 13: ...11 Operation flow chart Chapter 1 Product Characteristics LP 528 REV 8 01 14 ...

Страница 14: ...12 Operation flow chart Chapter 1 Product Characteristics LP 528 REV 8 01 14 ...

Страница 15: ...13 Wiring Diagram Chapter 1 Product Characteristics LP 528 REV 8 01 14 ...

Страница 16: ...14 Wiring Diagram Chapter 1 Product Characteristics Mixing Valve LP 528 REV 8 01 14 ...

Страница 41: ...39 Installer Setting Mode Control panel mode Chapter 3 How to use control panel LP 528 REV 8 01 14 ...

Страница 42: ...40 Chapter 3 How to use control panel LP 528 REV 8 01 14 ...

Страница 67: ...65 Chapter 4 Troubleshooting 1 Flame Detection LP 528 REV 8 01 14 ...

Страница 69: ...67 4 Storage DHW OP CH Overheat Exhaust Overheat Sensor Chapter 4 Troubleshooting LP 528 REV 8 01 14 ...

Страница 70: ...68 Error code Chapter 4 Troubleshooting LP 528 REV 8 01 14 ...

Страница 71: ...69 Chapter 4 Troubleshooting LP 528 REV 8 01 14 ...

Страница 72: ...70 Chapter 4 Troubleshooting LP 528 REV 8 01 14 ...

Страница 106: ...104 1 Cabinet Replacement Parts Chapter 7 Repair Part Diagram LP 528 REV 8 01 14 ...

Страница 107: ...105 Chapter 7 Repair Part Diagram LP 528 REV 8 01 14 ...

Страница 108: ...106 2 Combustion System Replacement Parts Chapter 6 Repair Parts Diagram LP 528 REV 8 01 14 ...

Страница 109: ...107 Chapter 7 Repair Part Diagram LP 528 REV 8 01 14 ...

Страница 110: ...108 Memo LP 528 REV 8 01 14 ...

Страница 111: ...109 Memo LP 528 REV 8 01 14 ...

Страница 112: ...110 Memo LP 528 REV 8 01 14 ...