LCBS CONNECT SOLUTION

31-00118EFS—01

14

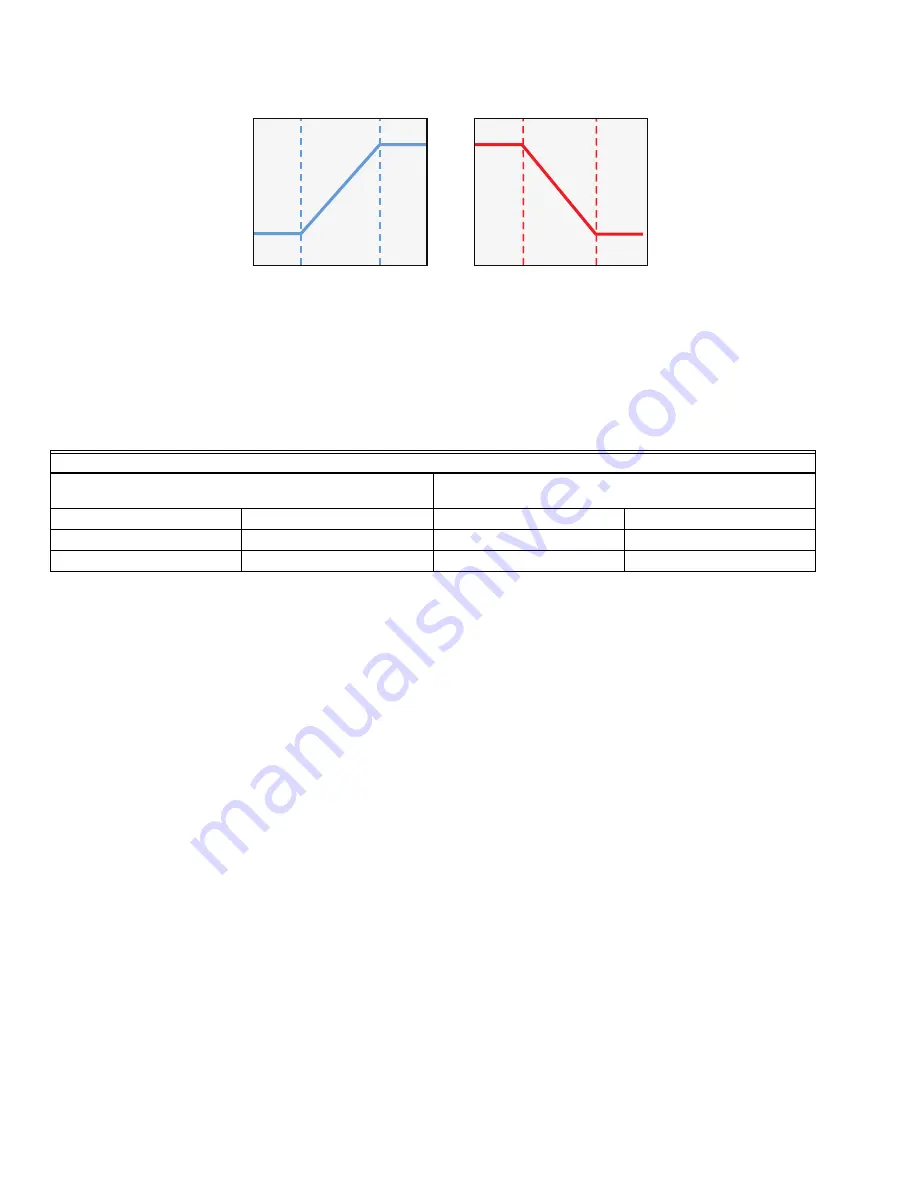

Fig. 4.

A direct acting control loop is one where the output increases as the input sensor value rises above the set point.

A reverse

acting control loop is one where the output increases as the input falls below the set point. Direct or reverse acting should

be selected based on the application requirements with the consideration that set point is the "no load" value of the

measured variable and with 0% output the energy input should be the closed or off. The physical outputs can be

configured to match the controlled devices (normally open, normally closed, energized on, energized off, etc.).

The proportional calculation determines proportional error (Ep). Proportional error is the deviation from set point of the

sensed medium (input sensor) divided by the throttling range expressed in units of the input sensor. The set point is the

value of the input sensor at which the control loop is satisfied. When the input sensor value is at set point there is no

proportional error and the output is 0%. The throttling range is the amount of change in the sensed medium required to

drive the output from 0 to 100%. By definition, in proportional control the input value must deviate from set point to

initiate a change in the output.

Selected Throttling Range must be narrow enough to provide good control without becoming unstable. The throttling

range is determined by a number of factors such as the control application, the response time to the equipment being

controlled, and the control algorithm being used. The narrower (smaller) the throttling range, the more precise the control

and the wider (larger) the throttling range, the more stable the control. The objective is setting the throttling range to

achieve the optimum balance between precision and stability.

Set point and Differential Refresher - On Off, Digital Control

The following is a refresher course for you and describes the relationship between set point and differential for heating

and cooling. These settings are typically programmed for each control loop and each on off output.

In heating mode, the differential is below the set point. The output relay de-energizes when the temperature rises to the

set point. As the temperature drops to the set point minus the differential, the relay energizes. You will also see this

referred to as "direct acting," where increased control action is in direct relationship to increased temperature value.

APPLICATION EXAMPLES

DIRECT ACTING. CONTROL DEVICE INCREASES AS

MEASURED VALUE INCREASES

REVERSE ACTING. CONTROLLED DEVICE DECREASES

AND MEASURED VALUE INCREASES

COOLING

STATIC PRESSURE

HEATING

LIGHTING

DEHUMIDIFICATION

CHILLED WATER PUMP

HUMIDIFICATION

STATIC PRESSURE

MIXED AIR

CONDENSER WATER PUMP HOT WATER PUMP

70°F

72°F

74°F 76°F

78°F

SENSOR INPUT VALUE

EXAMPLE: COOLING – DIRECT ACTING

SETPOINT 72°F THROTTLING RANGE 4°F

CONTROLLER OUTPUT %

100%

80%

60%

40%

20%

0%

THROTTLING

RANGE

SENSOR INPUT VALUE

EXAMPLE: HEATING – REVERSE ACTING

SETPOINT 76°F THROTTLING RANGE 4°F

CONTROLLER OUTPUT %

100%

80%

60%

40%

20%

0%

THROTTLING

RANGE

70°F

72°F

74°F 76°F

78°F

MCR36698

Содержание LCBS Connect

Страница 43: ...LCBS CONNECT SOLUTION 43 31 00118EFS 01 ...