61

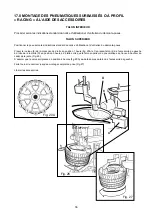

Lubricate the tyre beads with the special grease in order to avoid damaging them and to facilitate the mounting operations.

For 12 to 24 inch wheels lock the rim using the inner part of the clamps.

For 14 to 26 inch wheels lock the rim using the outer part of the clamps.

Note:

when working with rims of the same size it is not necessary always to lock and unlock the mounting bar; you only need to tilt and

return the arm (P) with the arm and the bar locked in their working positions.

Move the tyre so that the bead passes below the front section of the mounting head and is brought up against the edge of the rear section

of the mounting head itself.

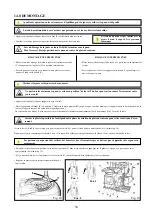

Keeping the tyre bead pressed down into the wheel rim channel with your hands, press down on the pedal (Z) to rotate the turntable

clockwise. Continue until you have covered the entire circumference of the wheel rim (Fig. 25).

• Insert the inner tube (if there is one) and repeat the same operations to mount the upper side of the tyre.

To prevent industrial accidents, keep hands and other parts of the body as far as possible from the

tool arm when the table top is turning.

Fig. 25

NOTE: Demounting and mounting are always done with the clockwise turntable rotation. Anticlockwise rotation

is used only to correct operator's errors or if the turntable stalls.

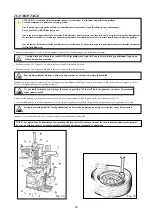

16.0 MOUNTING THE TYRE

WARNING: This checking of tyre and rim is of th utmost importance to prevent tyre explosion during the inflating

operations. Before beginning mounting operation make sure that:

The tyre and the cord fabric are not damaged. If you note defects DO NOT mount the tyre.

The rim is without dents and is not warped. Attention with alloy rims, dents cause internal micro-cracks not visible to

naked eye. This can compromise the rim and can also be a source of danger especially during inflation.

The diameter of the rim and tyre are exactly the same. NEVER try to mount a tyre on a rim if you cannot identify the

diameters of both.

During rim locking NEVER keep your hands under the tyre. For a correct locking operation set the tyre

exactly in the middle of turntable.

During arm tilting make sure that nobody stays behind the tyre-changer

Never keep your hands onto the wheel: the arm recovery to “working position” could set the operator

at risk of hand crushing between rim and mounting tool.

Fig. 24

Содержание Megamount 703 XL

Страница 80: ...80 24 DATI TECNICI TECHNICAL DATA DONNEES TECHNIQUES TECHNISCHE DATEN ...

Страница 83: ...83 110V 1PH ...

Страница 85: ......

Страница 86: ...Hofmann Megaplan GmbH Hauptstraße 59 A 5302 Henndorf Austria Telefon 43 6214 646612 Fax 43 6214 646622 ...