Dynamic Braking

Motor Contro

l

Ac

cess

or

ies

5–6

Dynamic Braking

Introduction

The purpose of dynamic braking is to improve the ability of the inverter

to stop (decelerate) the motor and load. This becomes necessary when an

application has some or all of the following characteristics:

• High load inertia compared to the available motor torque

• The application requires frequent or sudden changes in speed

• System losses are not great enough to slow the motor as needed

When the inverter reduces its output frequency to decelerate the load, the

motor can temporarily become a generator. This occurs when the motor

rotation frequency is higher than the inverter output frequency. This

condition can cause the inverter DC bus voltage to rise, resulting in an

over-voltage trip. In many applications, the over-voltage condition

serves as a warning signal that we have exceeded the deceleration

capabilities of the system. L300P inverters rated 20hp (15kW) and below

have a built-in braking unit, which sends the regenerative energy from

the motor during deceleration to the optional braking resistor(s).

External braking units may also be used if higher braking torques and/or

duty cycles are required. The dynamic braking resistor serves as a load,

developing heat to stop the motor just as brakes on an automobile

develop heat during braking.

The braking resistor is the main component of a braking resistor

assembly that includes an integral thermal fuse and thermally activated

alarm relay for safety. However, be careful to avoid overheating its resis-

tor. The thermal fuse and thermal relay are safeguards for extreme condi-

tions, but the inverter can maintain braking usage in a safe zone.

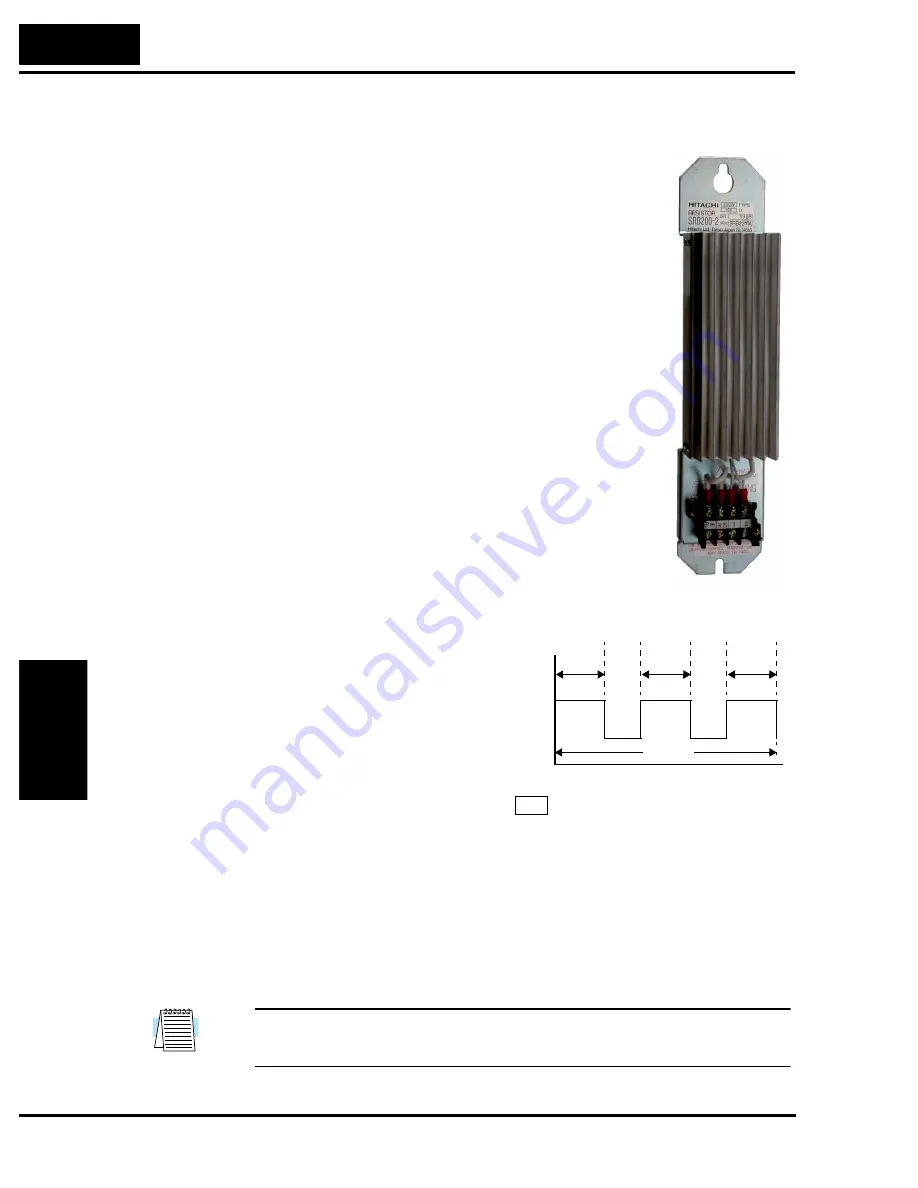

Dynamic Braking

Usage Ratio

The inverter controls braking via a duty

cycle method (percent of the time braking is

ON versus total time). Parameter B090 sets

the dynamic braking usage ratio. In the

graph to the right, the example shows three

uses of dynamic braking in a 100-second

period. The inverter calculates the average

percentage usage in that time (duty cycle %).

The percentage of usage is proportional to

the heat dissipated. If T% is greater than the

B090 parameter setting, the inverter enters

the Trip Mode and turns OFF the frequency

output.

Please note the following (for L300P–110LF/HF and L300P–150LF/HF).

• When B090 is set for 0%, dynamic braking is not performed.

• When the duty cycle value exceeds the limit set by B090, the inverter will trip (ending the

dynamic braking).

• The cable from the external resistor to the inverter must not exceed 5 m (16 ft.) length.

• The wires from the DB resistor to the inverter must not be bundled together with control or

signal wires.

NOTE:

Inverters rated 25hp (18.5kW) and above (L300P–185LF/HF to L300P–750LF/

1320HF) do not include an internal braking unit. Parameters B090, B095, and B096 do not

apply to these models.

Braking

Resistor

B90

BRD

Duty cycle

t1

t2

t3

...

+

+

+

(

)

100 seconds

------------------------------------------

100

×

=

t

t1

t2

t3

ON

OFF

100s

Содержание L300P Series

Страница 2: ......

Страница 42: ......

Страница 134: ......

Страница 195: ...Inverter System Accessories In This Chapter page Introduction 2 Component Descriptions 3 Dynamic Braking 6 5 ...

Страница 225: ...Glossary and Bibliography In This Appendix page Glossary 2 Bibliography 6 A ...

Страница 250: ......

Страница 251: ...Drive Parameter Settings Tables In This Appendix page Introduction 2 Parameter Settings for Keypad Entry 2 C ...

Страница 263: ...CE EMC Installation Guidelines In This Appendix page CE EMC Installation Guidelines 2 Hitachi EMC Recommendations 4 D ...

Страница 272: ......