86

Error

Description

Reason

Solution

E

740

Principle

axis

motor

rotate

abnormal

Speed

of

principle

axis

motor

exceed

normal

scope

Turn

off

power,

wait

for

a

while,

turn

on

again.

Change

the

principle

axis

motor

and

check

if

damaged;

if

unresolved,

change

the

main

board.

E

811

High

voltage

abnormal

The

power

supply

voltage

exceeds

the

specified

value.

。

Detect

a

high

signal

of

AC_OVDT,

check

power

voltage

and

related

circuits.

E

813

Voltage

is

extremely

low

Power

supply

isn’t

adequate

Sampling

UZKINanalog

quantity

is

too

low

,

please

check

power

supply

system

。

E

901

Fault

of

main

motor

driver

Fault

of

main

motor

driver

is

detected

Turn

off

the

power

for

a

while

and

try

turn

on

for

trail

again

。

E

903

Stepping

driving

is

abnormal

Stepping

driving

board

is

over

current

。

Turn

off

the

power

for

a

while

and

try

turn

on

for

trail

again

。

E

904

24V

power

system

is

abnormal

24V

is

overcurrent

。

Turn

off

the

power

for

a

while

and

try

turn

on

for

trail

again

。

E

906

Main

motor

is

out

of

control

Fault

of

Main

motor

is

out

of

control

is

detected

Turn

off

the

power

for

a

while

and

try

turn

on

for

trail

again

。

E

907

Xmotor

home

position

searching

is

abnormal

transducer

of

X

Motor

home

position

does

not

alter

Turn

off

power,

check

if

head

signal

circuit

board

CZ021,

control

box

X9

is

loose

or

fall

off.

E

908

Ymotor

home

position

searching

is

abnormal

Y

motor

home

position

do

not

alter

Turn

off

power,

check

if

head

signal

circuit

board

CZ022,

control

box

X9

is

loose

or

fall

off.

E

910

Pressure

foot

motor

home

position

searching

is

abnormal

Pressure

foot

motor

home

position

transducer

do

not

alter

Turn

off

power,

check

if

head

signal

circuit

board

CZ025,

control

box

X9

is

loose

or

fall

off.

E

911

X

motor

is

busy

X

motor

master

in

action,

again

send

action

command.

Turn

off

power,

wait

for

a

while,

turn

on

again.

if

unresolved,

change

stepping

plate.

E

912

Y

motor

is

busy

Y

motor

master

in

action,

again

send

action

command.

Turn

off

power,

wait

for

a

while,

turn

on

again.

if

unresolved,

change

stepping

plate.

E

913

Thread

grasp

origin

search

error

Thread

grasp

origin

sensor

does

not

change

Turn

off

power,

check

if

head

signal

circuit

board

CZ026,

control

box

X9

is

loose

or

fall

off.

E

914

poor

transmission

Feed

and

principle

axis

out

‐

sync

Turn

off

power,

wait

for

a

while,

turn

on

again.

Feeding

angle

is

wrong

E

915

Main

circuit

board

‐

operate

panel

communication

error

Communication

between

main

circuit

board

and

operate

panel

is

unavailable.

Turn

off

power,

wait

for

a

while,

turn

on

again.

Check

if

there

is

some

connection

problem

with

cables,

main

board,

and

operate

panel.

Содержание HK2900

Страница 1: ......

Страница 7: ...6 缝纫机机头 布压脚 线架装置 操作盘 电源开关 控制箱 踏板开关 2 各部的名称 1 主机的名称 ...

Страница 23: ...22 外部线缆插头上有对应的编号 请仔细查看后对应接插 示意图 5 6 图 5 图 6 10 电缆线的链接 ...

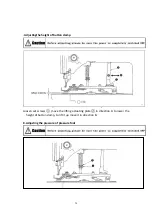

Страница 24: ...23 11 马达护罩的安装 把马达护罩 用附属的螺丝安装到缝纫机主体上 12 电线的处理 放倒缝纫机时 请确认机头支杆安装在机台上 在放倒缝纫机的状态 连接电线 如图所 示用线束夹 捆紧 ...

Страница 27: ...26 穿过机针的线应留出 4cm 左右 3 上线的穿线方法 4 梭壳的取下插入 1 打开旋梭外罩 2 拨起旋梭壳 的抓脚 取出梭壳 3 插入时 请把梭壳深深插入旋梭轴 并关 闭抓脚 ...

Страница 76: ...75 机台台板 ...

Страница 93: ...12 2 Operation ...

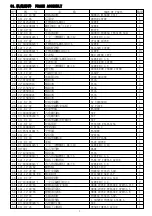

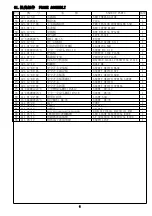

Страница 169: ...88 Table diagram ...

Страница 170: ......

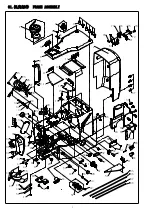

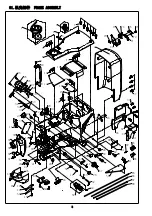

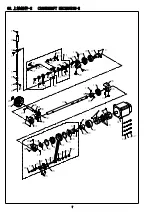

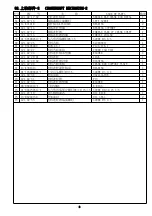

Страница 184: ...1 4 5 3 6 3 8 9 10 12 11 15 13 14 18 7 16 17 6 19 19 05 剪线部件 THREAD TRIMMER MECHANISM COMPONENTS 2 3 3 3 20 13 ...

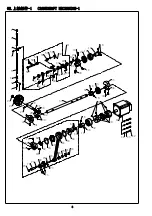

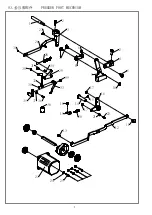

Страница 190: ...17 12 11 10 9 7 6 4 5 1 3 14 16 15 8 3 2 13 18 20 19 21 19 HK2903专用部件 1 EXCLUSIVE PARTS FOR HK2903 1 ...

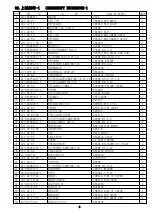

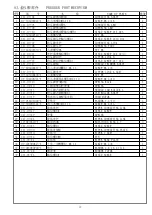

Страница 194: ...2 4 5 6 7 9 2 3 6 8 1 23 HK2903 专用附件 EXCLUSIVE ACCESSORIE PARTS FOR HK2903 ...