Ductless Troubleshooting

Phone: 866.814.3633 (option 3) Email: [email protected] Online: www.HaierDuctlessHelp.com

Rev. 04-20

PAGE 54

●

Checking System Components

Checking Outdoor Unit Components

NOTE: Component resistance readings shown in this section

are for reference only. Actual resistance values may

based on model being tested.

Component readings shown below are based on the models

of 1U*EH2VHD outdoor unit.

Step 3

Re-seat the plug on the connector at the conclusion of the

test.

Checking the EEV Coil

Step 1

Disconnect the EEV coil from the PCB for this test. Failure

to do so may provide inaccurate readings.

Step 2

The resistance values of plus pin combinations are 46 Ohm.

Step 3

Re-seat the plug on the connector at the conclusion of the

test.

Testing of the following components requires the use of

needle probes. Avoid testing the connector end of the plug,

as damage to the internal sections of the plug can occur.

Checking the Outdoor Unit Sensors

NOTE: Use respective temperature / sensor chart for sensor

type being tested.

Compressor discharge sensor

Suction sensor

Defrost temperature sensor

Ambient sensor

Step 1

Disconnect the sensor plug from the control board for this

test. Failure to do so may provide inaccurate readings.

Step 2

Using k-type temperature probe, determine the temperature

of the sensor being tested.

Step 3

Using an ohmmeter, check the resistance value of the sensor.

Step 4

Referring to the temperature / resistance table for the sensor

being checked, verify the resistance value corresponds to the

temperature checked in Step 2.

Replace the sensor if the reading is open, shorted, or outside

Step 5

Re-seat the plug on the connector at the conclusion of the

test.

Checking the Reversing Valve Coil

Step 1

Disconnect the reversing valve plug from the PCB

for this test. Failure to do so may provide inaccurate read-

ings.

Step 2

Using an ohmmeter, check the resistance value of the coil.

The resistance value of the coil should be 1.2 kilo ohms to

1.8 kilo ohms. Replace the valve c

ERROR CODES and Troubleshooting

Checking the DC Fan Motor

Step 1

Using needle probes, check the DCV at the back of the fan plug on

the PCB. The values are:

Red to black: +310 VDC

White to black: +15 VDC

Yellow to black: 1-4 VDC when running; 0 VDC when there is no call

for heating or cooling

Blue to black: pulsing 0-8 VDC when running; 14 VDC when there is

no call for heating or cooling

Checking the Compressor Windings

Step 1

Disconnect wiring from terminals U, V and W of the IPM.

Step 1

Using an Ohmmeter, check the resistance value of the

compressor windings. Measure between wires U and V,

U and W, and V, and W.

The resistance value of the windings should be balanced

(equal). If the resistance values are not equal, verify the

wiring and connections to the compressor as well as the

compressor itself. Repair or replace as needed.

Содержание AW09EH2VHD

Страница 2: ... This page intentionally left blank ...

Страница 4: ...Failure to follow any CAUTION may in some cases result in grave consequences ...

Страница 6: ...PAGE 6 ...

Страница 9: ...5VDC and 15VDC pulsing communication connection between the PCB and the IPM ...

Страница 10: ......

Страница 11: ......

Страница 12: ......

Страница 13: ......

Страница 14: ......

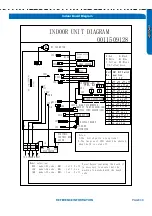

Страница 15: ...Connector for coil temperature sensor and room temperature sensor ...

Страница 17: ......

Страница 19: ......

Страница 22: ......

Страница 23: ......

Страница 26: ...PAGE 32 ...

Страница 50: ...Error Code E7 LED1 15 Flash Wiring Diagram Reference PAGE 50 ERROR CODES and Troubleshooting ...

Страница 57: ...PAGE 57 Ambient Defrost and Pipe Sensor Tables Discharge Sensor Tables ...