P/N G610B

April, 2016 (Rev 0)

Page 9

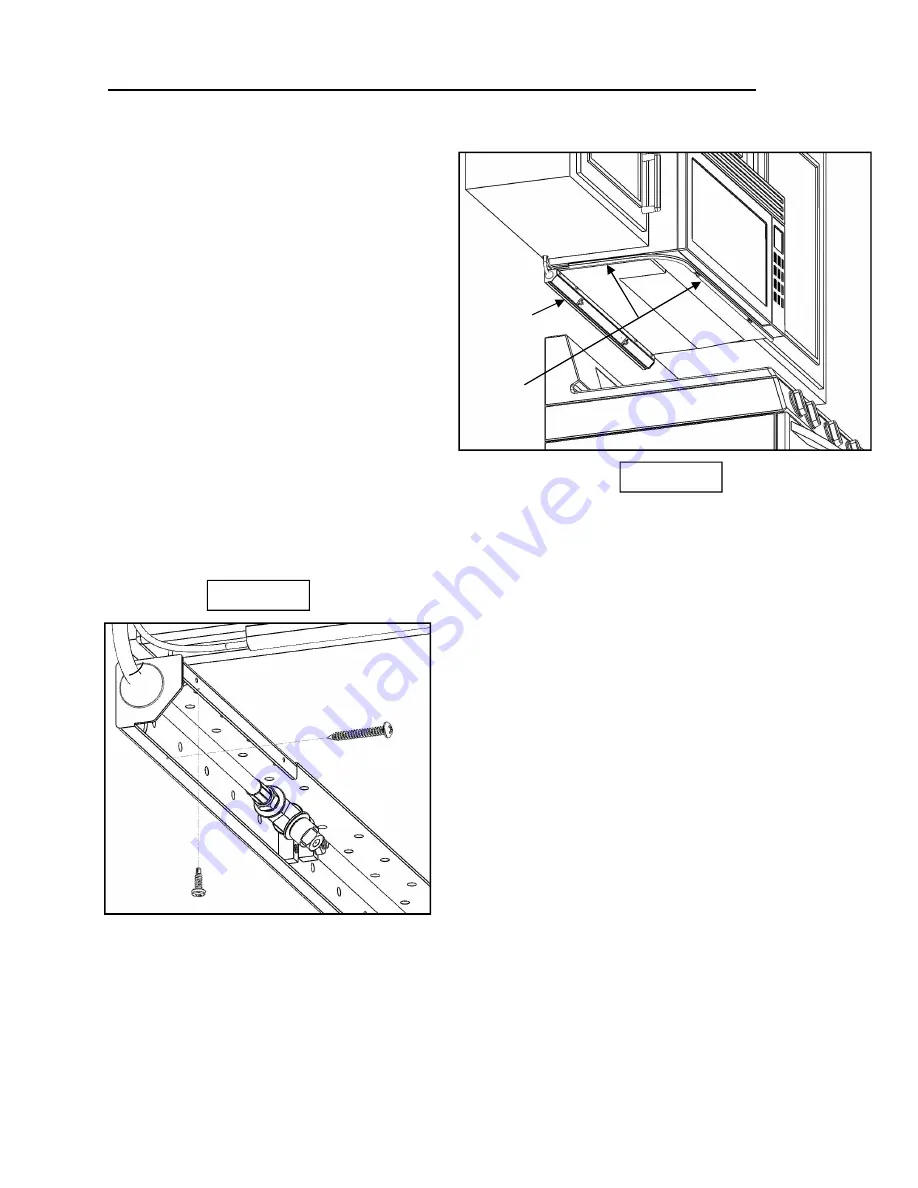

FIGURE 7

FIGURE 8

Distribution

Assembly

Sensor

Assembly

SYSTEM INSTALLATION INSTRUCTIONS (Cont'd)

8. Attach the Sensor Assembly to the bottom of the

Hood/Microwave Hood by placing it near the front

edge and allowing the inline magnets to secure it in

place. It should be installed between 12 and 17

inches away from the rear wall, and as far away

from the wall as the hood will allow within the

specified range (See

Figure 5

). Make sure the

bottom of the hood is cleaned of all grease before

installing the sensor assembly. After installing the

sensor assembly along the front, the remaining

portion of the tube should run along the bottom

side of the hood towards the wall. Next, proceed to

feed the sensor wire through the route you planned

in steps 3-4. (See

Figure 7

)

9. If you are not using the Wireless Tx/Rx, then now is

the best time to run the interconnect cable from the

location of the fuel shut-off up to the cabinet where

the main CPU will be located. You may choose to

run the interconnect cable through a wall mount

conduit or raceway to the bottom of the cabinets

and then follow the same route as the sensor wire,

or you may choose to route it through the wall and

up to the cabinet.

10. The distribution assembly must be centered above

the cooking appliance when it is installed. Firmly

mount the distribution housing in the corner formed

by the back wall and the hood. This is done by

using two self-tapping screws to anchor into the

hood above and two 1-1/4” screws to secure to the

wall behind. Screws in the wall must be located

where they will go into the walls studs or into a wall

anchor. Screws going into the hood must be

located where they will not damage any part of the

hood including wiring, electronic components, etc.

A total of four screws must be installed. After the

housing is mounted, place the Nozzle/Hose

assembly in the housing with the hose on the same

side as your planned route. Slide the 2 clamps onto

the mounting posts in the hosing. Center the

Nozzle assembly and then secure it into place

using the 11/32” Nut Driver to gently tighten the two

clamp nuts onto the stainless steel pipe.

(See

Figure 5, 7, 8 and 9

)

11. Route the stainless steel braided hose through the

route planned in steps 3 and 4. You may need to

place a piece of tape over the end of the quick

coupling to prevent debris from entering the hose

as you pull it through the route. Once the hose is

pulled into the cabinet, route it through the housing

and connect it to the cylinder using the quick

coupling located under the handle.

(See

Figure 6

)

12. Reinstall the main CPU enclosure back onto the Guardian G600-B System Enclosure / Extinguisher Assembly

and tighten the three screws loosened in step 6. Route and connect the sensor wires, solenoid wire and

pressure gauge wire to the main CPU. (See

Figure 2 and 3

) Note: sensor 1 and sensor 2 plugs are

interchangeable and can be plugged into either connector.

13. Attach the green ground wire to an earth ground by using a self-tapping screw and fastening it to a grounded

metal part of the hood. (See

Figure 2

)

Permit Number:

20-04649