Deferrisation

GENO-mat FE-Z Deferrisation System

Order no. 025 153 940-inter Edited by: nkes-mrie G:\BA-153940-INTER_025_GENO-MAT_FE-Z.DOC

25

1.3 Reading the

operating status

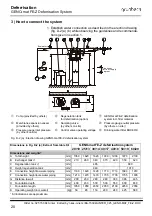

The current operating state may be read from the position of the ref-

erence point (Fig. F-1, Item 8) on the backwash wheel (Fig. F-1, Item

1).

The reference point (Fig. F-

1, Item 8) lies opposite

the reference arrow (Fig.

F-1, Item 7).

Operating mode: pure water is available.

All other settings from the

reference point (Fig. F-1,

Item 8).

Backwash; the backwash wheel (Fig. F-

1, Item 1) turns clockwise; the progress

of the backwash can be read from the

position of the reference point (Fig. F-1,

Item 8).

The day disk (Fig. F-1, Item 4) turns counter-clockwise once in 12

days. The red reference arrow (Fig. F-1, Item 3) points to the posi-

tion where a switching pin turned outwards releases a backwash. In

the operating mode, the distance between the reference arrow (Fig.

F-1, Item 3) and the following switching pin which is turned outwards

is an indication for the number of days until the next backwash.

1.4 How to release a

manual backwash

Manual regeneration should be released if

the differential pressure of the deferrisation system is more than

0.3 bar above normal before the timer control releases the back-

wash.

the systems are restarted after longer periods of standstill.

maintenance or repair work has been carried out.

Irrespective of the set backwash interval and the time, the backwash

can be released manually at any time.

1. Check operating state.

Only in operating mode:

2. Turn backwash wheel (Fig. F-1, Item. 1) to the right by one catch

(pay attention to the snap!).

The deferrisation system starts the backwash process, the back-

wash wheel (Fig. F-1, Item 1) slowly turns clockwise. After approx. 3

hours, the backwash is terminated and the white reference point

(Fig. F-1, Item 8) is located opposite of the black reference arrow for

the current time again (Fig. F-1, Item 7).