Model T27710 (Mfd. Since 04/16)

-33-

Review the troubleshooting and procedures in this section if a problem develops with your machine. If

you need replacement parts or additional help with a procedure, call our Technical Support.

Note: Please

gather the serial number and manufacture date of your machine before calling.

SECTION 6: SERVICE

Troubleshooting

Operation

Symptom

Possible Cause

Possible Solution

Splitting wedge

moves forward

and backward too

slowly, or does

not move in either

direction.

1. Hydraulic tank empty or low.

2. Tank suction filter clogged.

3. Air in hydraulic system.

4. Control lever linkage at fault.

5. Pump or pump relief valve at fault.

6. Hydraulic control valve at fault.

7. Damaged ram piston seals.

1. Fill tank to required level (

Page 29).

2. Clean suction filter (

Page 30). Service hydraulic

system.

3. Bleed air out of system by moving wedge back/forth

several times until it moves smoothly.

4. Replace/repair bent or worn linkage to provide full

range of travel.

5. Replace pump and flush/service hydraulic system

(

Page 30).

6. Replace valve and flush/service hydraulic system

(

Page 30).

7. Replace ram assembly and flush/service hydraulic

system (

Page 30).

Splitting wedge

moves forward

too slowly or not

at all, but retracts

correctly.

1. Control lever linkage at fault.

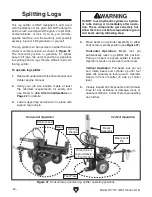

2. Splitting wedge dull; log unsuitable for

splitting.

3. Hydraulic fluid too low or contaminated.

4. Hydraulic control valve at fault.

5. Damaged ram piston seals.

1. Replace/repair bent or worn linkage to provide full

range of travel.

2. Sharpen wedge; avoid splitting logs with twisted

grain, numerous knots, or high moisture content.

3. Replace/fill tank to required fluid level (

Page 29).

4. Replace valve and flush/service hydraulic system

(

Page 30).

5. Replace ram assembly and flush/service hydraulic

system (

Page 30).

Splitting wedge

retracts too slowly

or not at all, but

moves forward

correctly.

1. Control lever linkage at fault.

2. Hydraulic control valve at fault.

3. Damaged ram piston seals.

1. Replace/repair bent or worn linkage to provide full

range of travel.

2. Replace control valve.

3. Replace ram assembly and flush/service hydraulic

system (

Page 30).

Splitter will not split

wood or splits it too

slowly.

1. Splitting wedge dull.

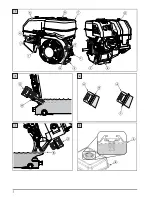

2. Engine oil level too low or contaminated.

3. Hydraulic tank filter clogged.

4. Splitting wood against grain.

5. Air in hydraulic system.

1. Sharpen wedge (

Page 32).

2. Add/replace engine oil.

3. Replace hydraulic tank filter (

Page 31).

4. Split wood with grain instead of against grain.

5. Bleed air out of hydraulic system.

Hydraulic tank fluid

burnt or has tan

discoloration.

1. Hydraulic fluid old or contaminated with

water.

1. Replace hydraulic fluid (

Page 30).

Note: Refer to the Kohler engine manual for engine-related troubleshooting.

Содержание T27710

Страница 40: ...38 Model T27710 Mfd Since 04 16...

Страница 44: ......

Страница 45: ......

Страница 46: ......

Страница 47: ......

Страница 48: ......

Страница 49: ......

Страница 50: ......

Страница 51: ......

Страница 52: ......

Страница 53: ......

Страница 54: ......

Страница 55: ......

Страница 56: ......

Страница 57: ......

Страница 58: ......

Страница 59: ......

Страница 60: ......

Страница 61: ......

Страница 62: ......

Страница 115: ...53 18 690 01 Rev C KohlerEngines com...

Страница 116: ...54 KohlerEngines com 18 690 01 Rev C...

Страница 117: ...55 18 690 01 Rev C KohlerEngines com...

Страница 118: ...56 KohlerEngines com 18 690 01 Rev C 2015 by Kohler Co All rights reserved...