44

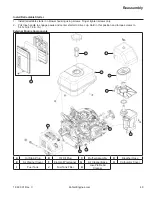

Reassembly

KohlerEngines.com

18 690 01 Rev. C

5. Apply a light coating of lithium grease to seal lips

after installing.

Install Governor Assembly

1. Install governor shaft through gear and add thrust

washer to shaft.

2. Install governor gear assembly into crankcase using

a press, or a drift with light taps, until tip of shaft is

78.862 mm (3.105 in.) below machined gasket

surface of crankcase.

3. Install thrust washer and cup on governor gear shaft.

4. Install thrust washer onto governor cross shaft and

slide shaft up through inside of crankcase.

5. Install

second

fl

at washer onto shaft. Position shaft

so

fl

at index end of shaft faces left (9 o'clock

position). Insert hitch pin so end of pin comes in

contact with raised boss on housing, limiting inward

movement of shaft.

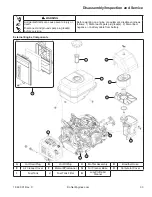

Install Oil Sentry

™

System

1. Mount Oil Sentry

™

fl

oat into crankcase using screws.

2. Route wire lead grommet assembly through

crankcase housing.

3. Install nut onto grommet assembly external stud and

tighten securely.

Install Crankshaft

Carefully slide

fl

ywheel end of crankshaft through main

bearing and seal.

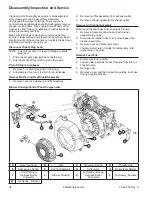

Install Connecting Rod with Piston and Rings

Connecting Rod Details

A

C

D

A

B

A

Match Marks

B

Offset

C

Dipper

D

Oil Hole

NOTE: If piston and/or connecting rod has been

changed or removed, be sure piston index mark

and end cap dipper orientation are correct

before installation.

NOTE: Install oil control ring assembly

fi

rst, middle

compression ring second, and top compression

ring last. Oil control ring assembly is a three-

piece design, and consists of a top rail,

expander ring, and bottom rail.

1. Install piston with index mark on piston to connecting

rod with dipper of end cap down.

2. Install connecting rod with offset down and oil hole in

4 o’clock position shown. Match marks should align

as shown.

3. Install and stagger piston rings in grooves.

4. Lubricate cylinder bore, piston, piston pin, and piston

rings with engine oil. Compress rings using a piston

ring compressor.

5. Lubricate crankshaft journal and connecting rod

bearing surfaces with engine oil.

6. Be sure index mark on piston is facing down toward

base of engine. Use a hammer handle or rounded

wood dowel and gently tap piston into cylinder. Be

careful oil ring rails do not spring free between

bottom of ring compressor and top of cylinder.

7. Install connecting rod end cap to connecting rod so

dipper is down and match marks are aligned.

8. Torque connecting rod screws in increments to

12 N·m (106 in. lb.).

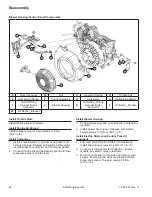

Install Valve Tappets and Camshaft

Crankshaft and Camshaft Timing Marks

A

A

A

Timing Marks

1. Identify valve tappets as to their proper locations.

Lubricate face and stem of each tappet with engine

oil. Install each into its respective bore.

2. Lubricate camshaft bearing surfaces and cam lobes

as well as camshaft bore in crankcase with engine

oil.

3. Rotate crankshaft to TDC so timing mark (dimple) on

crankgear (smaller gear) is in 4 o’clock position.

Install camshaft into crankcase, aligning timing

marks on gears.

Содержание T27710

Страница 40: ...38 Model T27710 Mfd Since 04 16...

Страница 44: ......

Страница 45: ......

Страница 46: ......

Страница 47: ......

Страница 48: ......

Страница 49: ......

Страница 50: ......

Страница 51: ......

Страница 52: ......

Страница 53: ......

Страница 54: ......

Страница 55: ......

Страница 56: ......

Страница 57: ......

Страница 58: ......

Страница 59: ......

Страница 60: ......

Страница 61: ......

Страница 62: ......

Страница 115: ...53 18 690 01 Rev C KohlerEngines com...

Страница 116: ...54 KohlerEngines com 18 690 01 Rev C...

Страница 117: ...55 18 690 01 Rev C KohlerEngines com...

Страница 118: ...56 KohlerEngines com 18 690 01 Rev C 2015 by Kohler Co All rights reserved...