Model G0901 (Mfd. Since 09/19)

-39-

Adjusting Wheel Shaft Position

If blade tracking (see

Page 38) is out of alignment,

the wheel shafts can be adjusted the change the

angle of the wheels. Properly adjusted wheels

should be parallel when the blade is tensioned.

If blade tracking appears to be out of alignment,

we recommend first replacing the blade before

adjusting blade shaft position. A worn belt can

become "bell mouthed" and throw off wheel

coplanarity just enough to cause problems. Guide

rollers out of adjustment can make the blade wob-

ble or wander. Before adjusting wheel shaft posi-

tion, check all of these. The blade wheels were

carefully factory set to be coplanar and parallel

before your saw was shipped so adjusting wheel

shaft position should be done as a last resort.

There are two adjustment bolts with hex nuts that

adjust the vertical wheel tilt and a through bolt

with hex nut that adjusts the horizontal wheel tilt

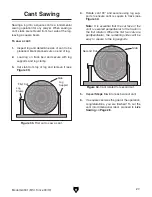

(see

Figure 60).

Figure 60. Wheel adjustment hub.

Hex

Nuts

Horizontal Tilt

Hex Bolt

Bottom Vertical

Tilt Hex Bolt

Top Vertical

Tilt Hex Bolt

To adjust wheel shaft position:

1. DISCONNECT SPARK PLUG WIRE!

2. Check blade tracking (see Page 38) and

determine which wheel needs to be adjusted,

and in which direction (see

Figure 61).

Wheels parallel and

coplanar.

Wheel is not

vertically aligned.

Wheel is not

laterally aligned.

Figure 61. Examples of wheel alignment.

3. Release blade tension by turning blade ten-

sion handle counterclockwise until handle

slackens.

4. Loosen hex nuts on wheel adjustment hub

(see

Figure 60).

Содержание G0901

Страница 56: ......