-36-

Model G0901 (Mfd. Since 09/19)

Symptom

Possible Cause

Possible Solution

Blade or teeth

break during

operation.

1. Foreign objects or tramp metal in log.

2. Blade is not properly tensioned.

3. Blade tracking is incorrect.

4. Dull or damaged blade.

5. Excessive feed rate/pressure.

6. Log is loose.

7. Wrong blade type or TPI.

8. Lubrication system at fault.

9. Blade teeth clogged.

1. Check log for foreign objects or tramp metal. Use

different log if necessary.

2. Adjust blade tension (

Page 23).

3. Adjust blade tracking (

Page 38).

4. Replace blade (

Page 23).

5. Reduce feed rate/pressure.

6. Secure log against supports; remove branches or

lumps that prevent even positioning.

7. Use correct blade.

8. Check lubricant level. Check for leaks.

9. Clean blade.

Blade slows

when cutting.

1. Blade is not properly tensioned.

2. Lubrication system at fault.

3. Drive belt is loose or slipping.

4. Belts are worn.

5. Dull or damaged blade.

6. Excessive feed rate/pressure.

1. Adjust blade tension (

Page 23).

2. Check lubricant level. Check for leaks.

3. Tension drive belt (

Page 37).

4. Replace belts (

Page 38).

5. Replace blade (

Page 23).

6. Reduce feed rate/pressure.

Blade does not

cut.

1. Dull or damaged blade.

2. Blade installed backwards.

1. Replace blade (

Page 23).

2. Re-install blade (

Page 23).

Machine has

excessive

vibration or

noisy operation.

1. Excessive sawdust buildup inside blade

compartment.

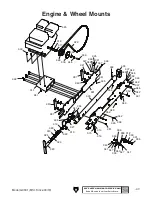

2. Engine is loose.

3. Log is loose.

4. Belts are worn.

5. Wheel bearings at fault.

1. Vacuum excess chips and sawdust.

2. Tighten fasteners; replace damaged fasteners.

3. Secure log against supports; remove branches or

lumps that prevent even positioning.

4. Replace belts (

Page 38).

5. Replace wheel bearings.

Blade is

twisting during

cut.

1. Excessive feed pressure.

2. Blade is not properly tensioned.

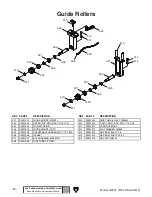

3. Blade cutting section too wide.

4. Dull or damaged blade.

1. Reduce feed pressure.

2. Adjust blade tension (

Page 23).

3. Adjust blade cutting section width (

Page 25).

4. Replace blade (

Page 23).

Throttle is

sluggish or

engine does

not slow to

an idle when

throttle handle

is released.

1. Throttle lever too tight.

2. Throttle cable damaged, corroded, or has

excessive builup inside housing.

1. Adjust throttle lever nut on engine until throttle lever

returns freely to stopped position.

2. Remove cable from housing. Clean/replace cable.

Operating Machine (Cont.)

Note: Refer to the Briggs & Stratton engine manual for engine-related troubleshooting.

Содержание G0901

Страница 56: ......