-44-

Model G0887 (Mfd. Since 01/19)

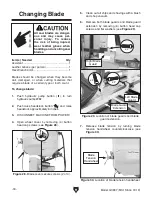

Adjusting

Support Vise Guide

The support vise guide provides workpiece sup-

port on the outfeed side of the cut, guiding cut-off

pieces down the cutoff chute. The support vise

guide should be adjusted when the cut had been

planned and the workpiece has already been

clamped in the vise. Use the adjustment controls

(see

Figure 52) to support the workpiece close to

where the blade will contact it.

To adjust support vise guide:

1. Loosen position lock handle (see Figure 52).

2. Move vise guide close to planned cut on vise

track (see

Figure 52).

3. Tighten position lock handle to secure posi-

tion.

4. Loosen extension lock handle (see Figure 52).

5. Adjust support vise guide until it contacts

workpiece (see

Figure 52).

6. Tighten extension lock handle.

7. Tighten fine-adjustment handle until plate is

secure against workpiece (see

Figure 52).

Figure 52. Support vise guide adjustment

controls.

Fine-Adjustment

Handle

Vise

Guide

The Model G0887 is equipped with a work stop

for repetitive cutting operations up to 24" long.

The work stop will need to be adjusted any time it

is removed or repositioned.

Adjusting Work Stop

To adjust work stop:

1. Adjust headstock to desired angle.

2. Lower headstock completely.

3. DISCONNECT MACHINE FROM POWER.

4. Screw work stop support rod into hole in

outfeed table with scale facing upward, as

shown in

Figure 53.

Flat

Edge

Support Rod

Figure 53. Work stop bar installed in table.

Outfeed Table

Hole

Position

Lock Handle

Extension

Lock Handle

Figure 54. Work stop bracket adjusted to 0

mark.

5. Slide work stop bracket onto support rod,

aligning body with "0" mark on rod scale (see

Figure 54).

0 Mark

Body

Support Rod

Содержание G0887

Страница 108: ......