-42-

Model G0887 (Mfd. Since 01/19)

The control panel has been calibrated at the fac-

tory to return the headstock angle to 0°.

To set angle to 0°:

1. Enter manual mode (

).

2. Turn on hydraulic pump ( ).

3. Raise headstock (

) to highest position.

Note: If headstock does not clear vise and

table components at highest position, set

headstock height higher so it will (see

Setting

Headstock Height on Page 40).

4. Press angle control button (

) to edit head-

stock angle setting (see

Figure 47).

5. Press both headstock increase and decrease

buttons and hold them until headstock digital

readout changes to zero (see

Figure 47).

6. Wait until headstock digital readout returns

to current angle, then use headstock angle

joystick to adjust headstock to 0°

(see

Figure 47).

Setting Angle to 0°

Figure 47. Headstock control section.

Headstock

Digital Readout

Input Light

Angle Control

Button

Increase

Button

Decrease

Button

Headstock Angle

Joystick

To avoid serious injury, always turn saw

OFF and allow blade to come to complete

stop before adjusting vise!

Using Vise

The Model G0887 vise consists of a movable

vise jaw that is manually positioned near the

workpiece, hydraulic vise clamping controls for

opening and closing, and adjustable vise clamp-

ing pressure.

Adjusting Vise Clamping Pressure

The Model G0887 features adjustable clamp-

ing pressure so the vise will not crush fragile

workpieces.

To adjust vise clamping pressure:

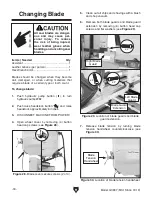

1. Loosen nut shown in Figure 48.

2. Adjust pressure adjustment knob until desired

pressure on gauge has been achieved, then

tighten nut to secure (see

Figure 48).

IMPORTANT: Do not exceed 497 PSI

(35 kg/cm²).

Tool Needed

Qty

Open-End Wrench 27mm .................................. 1

Figure 48. Vise clamping pressure adjustment

components.

Nut

Gauge

Pressure

Adjustment

Knob

Содержание G0887

Страница 108: ......