Model G0887 (Mfd. Since 01/19)

-25-

18. Press motor stop button (V). All motors

should turn

OFF.

19. Press hydraulic start/stop button (U) and

press raise headstock button (

O) to raise

headstock until indicator light on height con-

trol button (

H) illuminates.

20. Press vise close button (R) until vise close

button illuminates.

21. Press automatic operation button (N). Saw

will enter auto mode.

22. Turn feed rate dial (C) to a value other than

zero.

23. Press auto cycle button (D). Automatic cut

cycle should begin: coolant pump will start,

blade will start, vise will close, headstock will

lower, and bandsaw will perform cut. Then

blade will stop, headstock will raise to top of

its travel, and vise will open.

— If blade does shut off and headstock does

raise to top of its travel, lower limit stop is

working correctly. Continue to

Step 24.

— If blade does not shut off or headstock

does not raise, lower limit stop is not

working correctly. This safety feature must

work properly before proceeding with reg-

ular operations. Refer to

Page 72 to adjust

downfeed stop bolt.

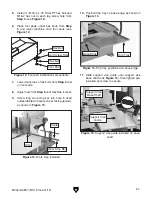

24. Remove (4) button head cap screws to open

blade cover (see

Figure 19).

Figure 19. Blade cover secure screws (2 of 4).

Note: Failure indicator door safety light (L)

will illuminate to indicate wheel cover is open

and that it must be closed before operation

can resume.

25. While staying safely away from blade, press

hydraulic start/stop button (

U), vise close but-

ton (

R), then automatic operation button (N).

— If blade does not start, blade cover safety

switch is working correctly. Proceed to

Step 26.

— If blade does start, immediately turn

machine

OFF and disconnect power.

Blade cover safety switch feature is not

working correctly. This safety feature must

work properly before proceeding with reg-

ular operations. Call Tech Support for

help.

26. Press Emergency Stop button (A), then close

wheel cover and secure.

Congratulations! Test Run is complete.

Recommended

Adjustments

The adjustments listed below have been per-

formed at the factory. However, because of the

many variables involved with shipping, we recom-

mend that you at least verify the following adjust-

ments to ensure accurate cutting results.

Step-by-step instructions on verifying these adjust-

ments can be found in

SECTION 7: SERVICE.

Factory adjustments that should be verified:

1. Downfeed Stop Bolt (Page 72).

2. Blade Tracking (Page 68).

3. Blade Guide Bearings (Page 66).

4. Squaring Blade to Table (Page 70).

5. Hydraulic Pressure (Page 53).

Содержание G0887

Страница 108: ......