EVO205D SAFE / SURE-Trak 6. MAINTENANCE

6-9

©GreenMech

Ltd

6-9

03/22

6.24 Chipper Disc Blade Re-Grinding

Examine set of chipper disc blades for damage. If

front face ‘A’ is worn, blade must be scrapped. If

chips have broken off cutting edge they can be re-

dressed provided that they do not go inside 90mm

diameter area.

Always regrind worst damaged blade first, as this

will establish target weight for remaining blades.

If large chips exist over less than 30% of

circumference, blade may be re-ground provided

large damaged area is not used for chipping.

Chips may be repaired by grinding a cutting edge

around damaged area using a bench grinder.

With chipper blade mounted on a mandrel re-grind

remainder of cutting edge at 43º as shown

Re-grind in increments of approximately 0.01mm

(0.004") until sharp edge is restored.

If re-grinding breaks into 90mm diameter area,

blade must be scrapped.

After re-grinding weight of blades within a set

must not vary by more than +/- 1gm (0.03oz).

Weight of each blade must not be less than

560gm (20oz)

Note:

Disc Blades use a patent Nord-Lock

washer pair together with a thinner Nyloc type

locking nut at an increased torque setting of

200Nm.

See fig 6.7.3 and Fig 6.7.4.

Ensure that both washers are assembled as a pair with faces of fewer teeth facing each other (fig 4).

Thread lubricant is recommended to ensure even torque. Do not use thread adhesive (e.g. Loctite).

Reuse:

Nord-Lock washers can normally be re-used when cleaned and re-lubricated.

Nyloc nuts should always be inspected for damage before reuse.

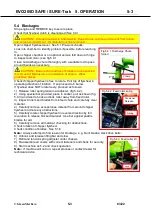

6.25 Shear Bar Removal (with slide hammer) and turning

1) Remove shear bar end cover.

2) Attach slide hammer to exposed thread in shear bar.

3) Carefully ease out bar with hammer (fig 6.25).

4) Turn bar to new cutting edge or replace.

5) Refit bar

6) Replace end cover.

Fig 6.25 Shear Bar removal

Shear bar

Slide hammer