EVO205D SAFE / SURE-Trak 6. MAINTENANCE

6-1

©GreenMech

Ltd

6-1

03/22

ROUTINE MAINTENANCE SCHEDULE

CAUTION! Always remove key and check for rotation before carrying out any maintenance.

Note:

Covers are bolted and only released by raising engine cover. Replace and secure all

covers when task is completed.

Instructions refer to all models except where stated for specific type (e.g. Road Tow, Track

model).

Action

Section

Page

DAILY

Check engine oil level and coolant (ref: engine manual)

6.2

– 6.3

6-3

Check hydraulic oil level

6.4

6-3

Check fuel level

6.5

6-3

Check all drive belts and clutch rod adjustment

6.6

6-3

Check condition of blades and retaining bolts

Note:

Special tools may be required

6.7

6-4

Clean radiator screen and around radiator

6.8

6-5

Check feed roller stop bar function

3.4

3-2

Check condition of tracks (Track model)

Refer to track manual

Check track gear, nuts, rollers and bearings (Track model)

Refer to track manual

First 50 hours

Check drive belt tensions and clutch rod adjustment

6.6

– 6.9

6-3 & 6-5

Check battery levels

6.13

6-6

Check hydraulic connections

6.18

6-7

Check all mountings

6.19

6-7

Check feed roller stop bar function

3.4

3-2

Service engine

Refer to engine manual

Weekly in addition to Daily actions

Blow out radiator core with air line

6.8

6-5

Check drive belt tension and clutch rod adjustment

6.6

– 6.9

6-3 & 6-5

Steam clean machine

6.10

6-5

Clean air cleaner

6.11

6-5

Check electrical connections

6.12

6-5

Check battery levels

6.13

6-6

Check feed roller stop bar function

3.4

3-2

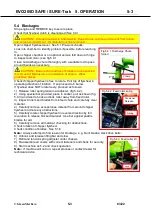

Grease all bearings and pivots

6.1, 6.16

6-2 & 6-6

Check hydraulic connections

6.18

6-7

Check all mountings

6.19

6-7

250 hours or 12 months, in addition to Daily and Weekly actions

Check all fluid levels

6.2, 6.3, 6.4

6-3

Check condition of bearings and pivots

6.16

6-6

Service engine

Refer to engine manual

Check track gear units, rollers and bearings

Refer to track manual

Replace return filter element

6.20

6-7

1000 hours in addition to 250 hour actions

Change hydraulic oil when replacing filter element

6.21

6-7