EVO205D SAFE / SURE-Trak 6. MAINTENANCE

6-6

©GreenMech

Ltd

6-6

03/22

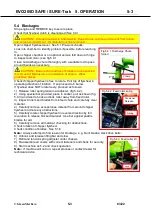

6.13 Battery

First 50 hours and weekly (Fig 6.13)

1) Remove right hand side covers to access battery.

2) Release stays if necessary.

3) Check electrolyte level and top up if required.

4) Reposition battery, and secure stays.

5) Refit cover and secure.

Removal

1) First disconnect negative (-) cable (black cap).

2) Disconnect positive (+) cable (red cap).

3) Remove clamp and carefully lift out battery.

4) Replace by connecting positive cable before negative.

5) Secure battery as 6.13.4 above.

CAUTION! Gases are explosive. Electrolyte is corrosive. Avoid sparks and spillage.

6.14 SureTrak Pitch Ram Pivots (Fig 6.14)

Remove cover to access track pitch ram pivots.

Grease as required.

6.15 Number not used

6.16 Bearings and Pivots

weekly

See paragraph 6.1 for routine lubrication.

250 hours or 12 months

Check rotating components for excessive movement and noise

in operation.

Replace as required.

6.17 Track Removal (Fig 6.17)

Support legs stowed under frame enable a track to be

raised or removed for maintenance.

1) Park machine on firm ground with track legs

extended.

2) Remove support legs from stowage and locate with

pins in frame brackets at each end of track to be raised.

3) Carefully Retract track legs until supported track is

clear of ground.

4) Proceed with track maintenance

– refer to track

manual.

5) Carefully reverse procedure to return machine onto

its tracks.

6) Remove support legs and stow under frame using pins to retain.

Fig 6.13 Battery

Battery

Covers

removed

Fig 6.14 Track pitch ram pivots

Cover

Fig. 6.17 Track removal

Support legs

Frame brackets

Track retracted off ground