EVO205D SAFE / SURE-Trak 6. MAINTENANCE

6-7

©GreenMech

Ltd

6-7

03/22

6.18 Hydraulic Connections

50 hours

With circuit diagram to follow hose routings, check all hoses and connections for leaks and

damage.

Replace any worn or damaged hoses with correct type and length.

Check routing before removal.

Replace hose free of strains, twists or kinks.

CAUTION! Ensure any residual pressure is released before dismantling.

CAUTION! Ensure hoses are refitted free of twists and kinks.

6.19 Mountings

250 hours

Check that all mounting bolts are tight.

6.20 Hydraulic Return Filter

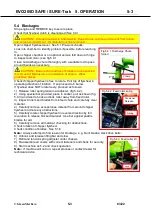

250 hours or 12 months (Fig 6.20)

1) Check oil is cool.

2) Unscrew canister and discard safely (fig 6.20).

3) Fit new filter canister.

CAUTION! Do not overtighten.

6.21 Hydraulic Oil Change

1000 hours

Remove hydraulic oil with suction pump at filler.

Replace suction filter.

Replace with new oil and filter of correct specification.

Dispose of waste oil according to local authority environmental procedures.

6.22 Fuses and No Stress System

There are two fuses.

A 40 amp in-line fuse protects engine pre-heat and start circuit.

A 20 amp fuse protects No Stress Power Protection System.

Note Operating speeds for No Stress system are factory set for particular machine models.

Fig 6.20 Hydraulic return filter

Hydraulic filter

(

spin-on canister)