GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors

12/2010

0062196

10

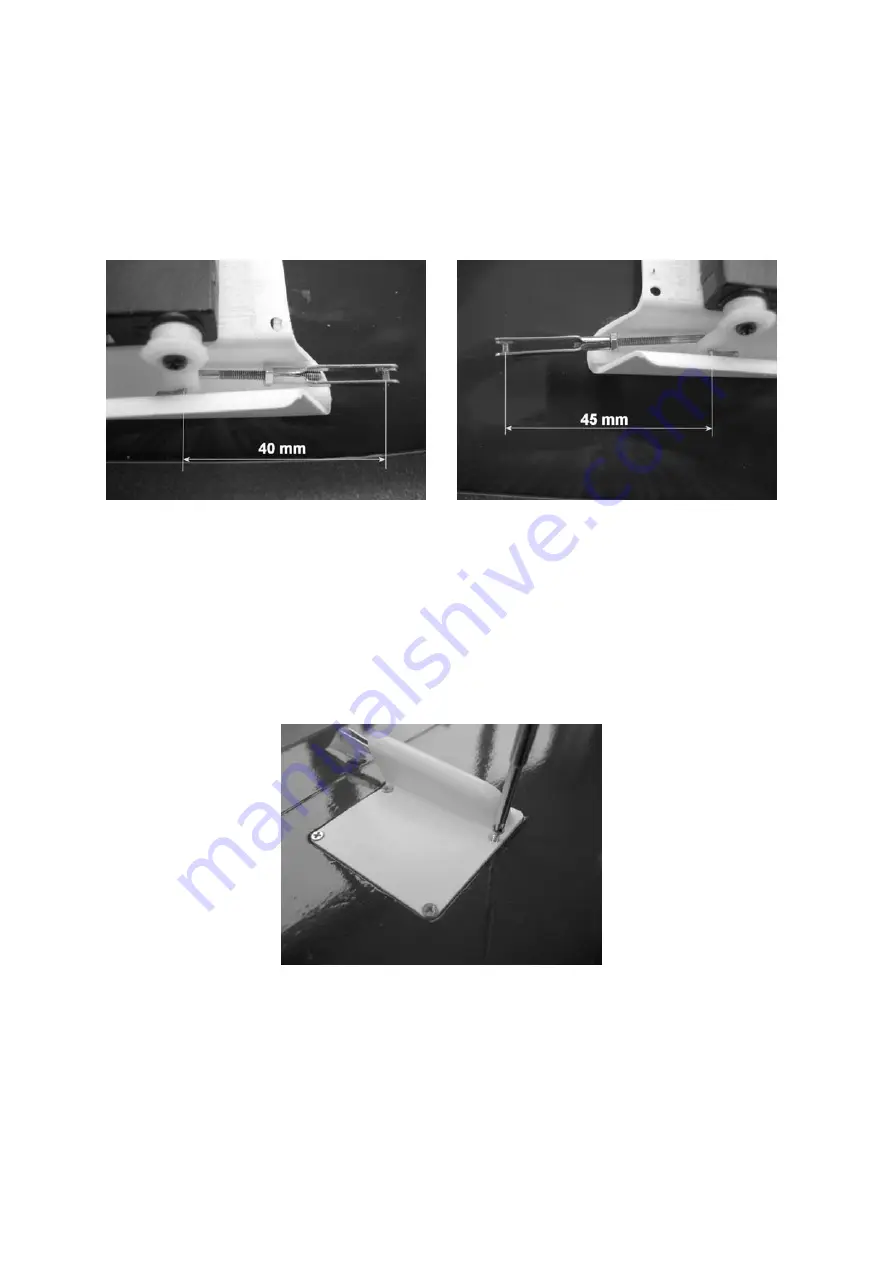

Each aileron and flap pushrod is assembled using an M2 threaded rod, an M2 nut

and an M2 clevis, as supplied in the kit. Note that the angled end of the aileron push-

rods must be formed in such a way that the distance between the linkage hole on the

servo output arm and the clevis linkage pin is 40 mm. For the flaps the same dimen-

sion is 45 mm. Final adjustment can be made later by screwing the clevis in or out on

the threaded rod, once you have screwed the servo cover in place.

It is essential to apply a drop of UHU schraubensicher (thread-lock fluid) between the

clevis and the locknut to prevent the clevis working loose.

You can now connect the clevises to the control surface horns, and fix the servo well

covers in place using the countersunk screws supplied; drill pilot-holes for the screws

beforehand. TIP: if you want the last word in aerodynamic efficiency you can

countersink the screw-holes in the moulding.

There are two possible methods of connecting the servos to the receiver: one is to

route the servo extension leads from the receiver out of the openings in the fuselage,

and then connect them to the extension leads in the wings when the model is rigged;

the other is to solder the extension leads to the wing servo quick-connectors, Order