Operation

36

313875J

b.

Place a waste container below the ratio check

valves. The next steps will cause the machine to

dispense material.

c.

Press

then

. The pump will travel to

bottom-most position.

d.

After the pump stops moving, press

then

press

. The pump will travel to the top-most

position.

NOTE:

During this process, the system learned the

mechanical limits of piston travel. If the pump did not

reach either piston mechanical travel limit for any rea-

son, repeat the procedure.

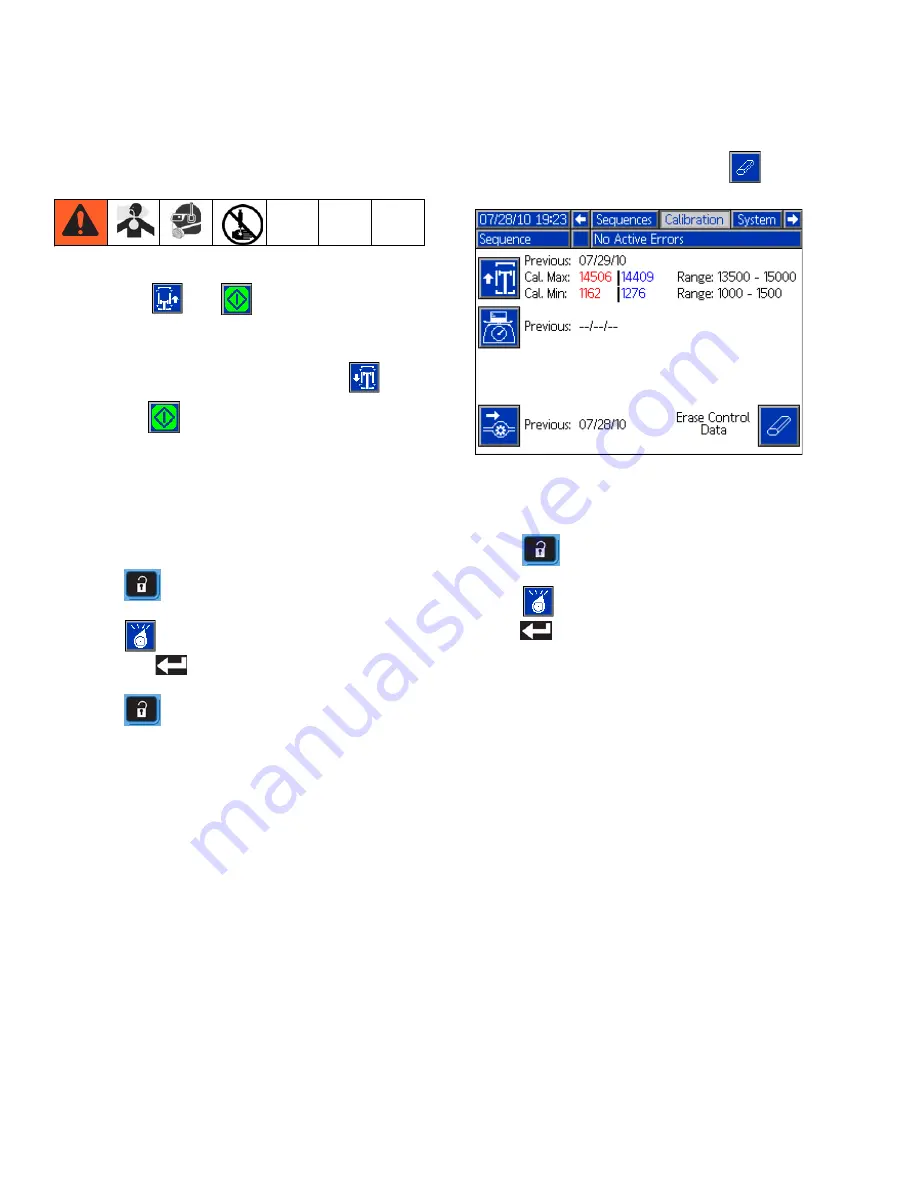

21. Press

to exit the Setup screens.

22. Press

repeatedly to select Operator mode

then press

to accept.

23. Press

to enter the Setup screens then press

left or right to navigate to the main Calibration

screen.

Flow Meter / No Flow Meter Calibration

24. If flow meters are installed, refer to

starting on page 39. If flow

meters are not installed, refer to

starting on page 40.

Flow Rate and Ratio Learning

25. At the main Calibration screen, press

to erase

all learned data.

NOTE:

This will not affect the weight calibration that was

just completed.

26. Press

to exit the Setup screens.

27. Press

repeatedly to select Shot mode then

press

to accept.

28. Select a defined shot that will provide a 10 second

or longer dispense at the flow rate and ratio

intended to be used during normal system opera-

tion.

NOTE:

If the ambient temperature is significantly below

68°F (20°C) then the flow rate for the machine will need

to be decreased. For most materials at 68°F (20°C) at a

2:1 to 3:1 ratio, a maximum flow rate of 335 g/s or 335

cc/s can be expected. The machine should not be oper-

ated much below 120 g/s or 120 cc/s at a 2:1 to 3:1 ratio.

Содержание VPM 12

Страница 9: ...A Red and B Blue Components 313875J 9...

Страница 11: ...Component Identification 313875J 11 FIG 2 Component Identification ti17702a AJ AF AL AD AC VPM 25 shown...

Страница 12: ...Component Identification 12 313875J VPM 12 FIG 3 ti17703a AL AA AK AH AE AB AD AF AJ AL AD AC AC...

Страница 50: ...Maintenance 50 313875J...

Страница 86: ...Appendix E USB Operation 86 313875J...