28

308783

Alarm Troubleshooting

WARNING

INJECTION HAZARD

To reduce the risk of a serious injury,

follow the

Pressure Relief Procedure

on page 17 before checking or servicing

the equipment.

CAUTION

Do not use the fluid in the line that was dispensed off

ratio as it may not cure properly.

If the system stops from an alarm condition, the alarm

output air will be active. The alarm outputs are de-

scribed below and on the following pages.

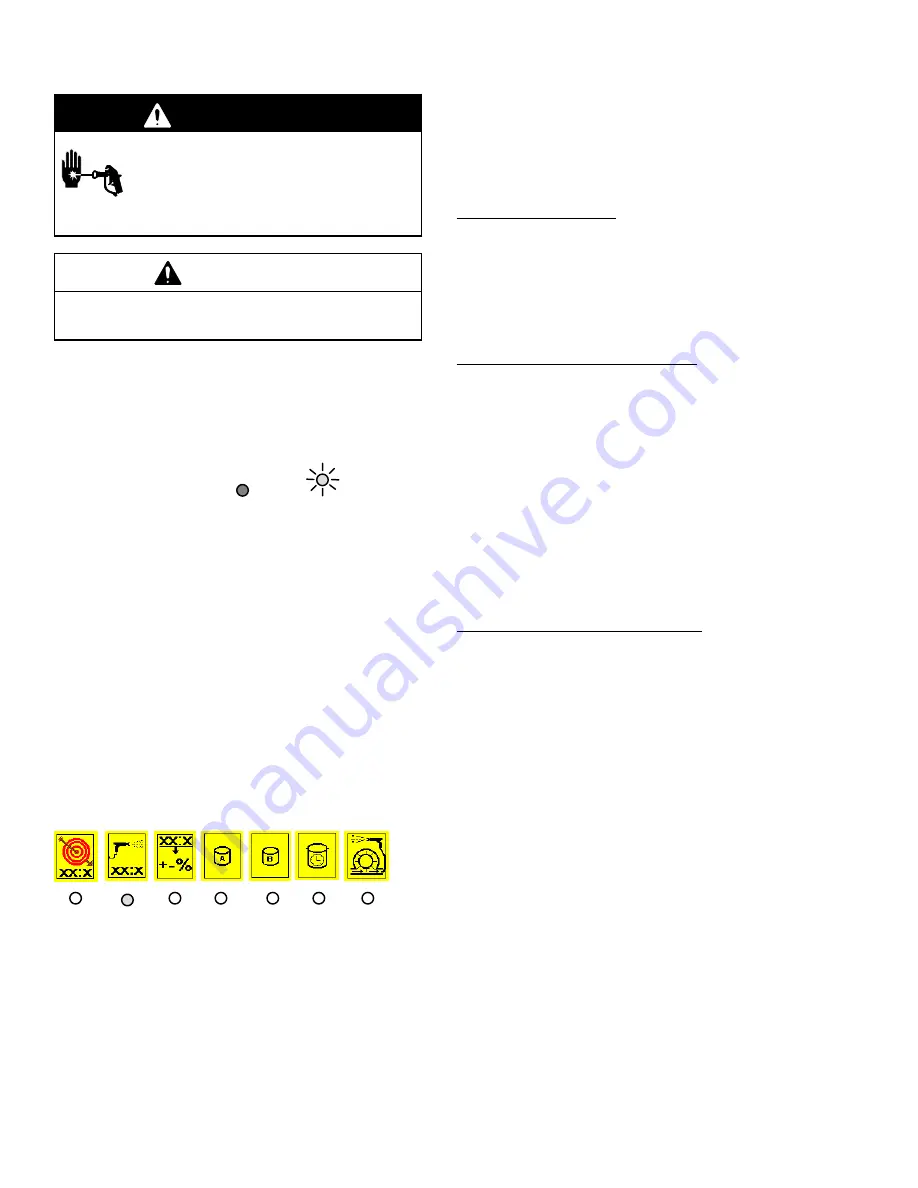

ProMix has alarms to alert you of a problem. If an

alarm is tripped, operation will stop and a front panel

light will glow a steady red or blink

below the

appropriate icon.

To Clear the Alarm and Restart the System

Except for Pot Life Exceeded, all alarms can be

cleared by turning the operator switch momentarily

from mix, to standby, to purge**, and back to standby.

Turn to mix to resume operation.

To clear a Pot Life Exceeded Alarm, the operator must

turn the operator switch to purge and purge the system

until the preset purge time is complete.

** To allow time for alarm resetting, there is a two sec-

ond delay after turning the operator switch to purge

before the actual purge begins.

Off Ratio Alarm

The system is off ratio when the amount of component

A compared to the amount of component B dispensed

in the previous cycle does not meet the tolerances that

have been set for the system.

Common Causes for an Off Ratio Alarm

The flow rate is too high

Highly unbalanced pressures from the fluid supply

system

Slow actuation of the component A or B valves

Checking the Flow Rate

If the alarm occurs while starting up the system after

purging, the flow rate was probably too high.

Restrict the gun needle travel to slow down the initial

fluid delivery rate until the fluid hoses are loaded with

material.

Checking for Unbalanced Pressures

If the alarm occurred after you have been spraying for

some time, the pressures from the fluid supplies could

be unbalanced.

1.

Check the component A and B pressures.

2.

If the pressures are not about equal,

adjust both

fluid supply pressures with the fluid regulators,

until the pressures are about the same.

3.

If the pressures are already about equal,

verify

that the component A and B valves are operating

properly.

Checking the Actuation of the Valves

Manually operate the valves by going to level 3 setup

and pressing and releasing the component A and then

the component B valve keys. The valves should snap

open and shut quickly.

If the valves move slowly, it could be caused by:

air pressure to the valve actuators is too low,

an interruption in the valve actuating air caused by

dirt or water in the air,

there is something restricting the solenoid or tubing,

the packings on the mix manifold dispense valves

are too tight,

a dispense valve knob is turned in too far. Refer to

page 18, step 3, for proper adjustment of the mix

manifold. You may want to put a piece of tape on

the knobs after they are properly set to discourage

anyone from changing the setting, or

the fluid pressure is high and the air pressure is

low. See

Accessories

, page 37, to order the high

pressure spring kit 239954.