15

RUBBER

COUPLING

WITH WORM

GEAR CLAMPS

RUBBER

COUPLINGS

WITH WORM

GEAR CLAMPS

COMBUSTION

AIR PIPE

(DIRECT VENT ONLY)

COMBUSTION

AIR PIPE

(DIRECT VENT ONLY)

VENT/FLUE

PIPE

VENT/FLUE

PIPE

90 PVC

ELBOW

(NON-DIRECT VENT)

90 PVC

ELBOW

(NON-DIRECT VENT)

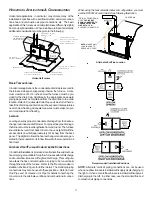

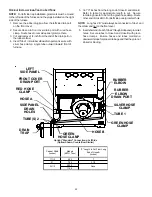

Standard Connections

OR

OR

UPFLOW COUNTERFLOW

A

LTERNATE

F

URNACE

C

ONNECTIONS

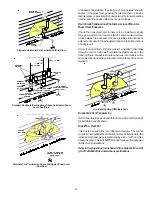

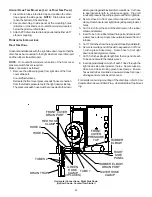

If the standard locations are undesirable for a specific installation,

alternate side panel locations are available for both combustion air

inlet and vent/flue pipe connections. These locations may be of

particular benefit to upright upflow installations requiring additional

access to an

A

coil, or to upright counterflow installations requiring

additional access to a filter or electronic air cleaner, or to horizontal

installations desiring vent/flue (and combustion air intake) piping

run vertically from the side of the cabinet.

NOTE:

Standard and alternate locations can be combined (i.e.,

an installation may use the standard combustion air intake loca-

tion but use the alternate vent/flue location or vice versa), if needed.

E

DGES

OF

SHEET

METAL

HOLES

MAY

BE

SHARP

.

U

SE

GLOVES

AS

A

PRECAUTION

WHEN

REMOVING

HOLE

PLUGS

.

WARNING

A

LTERNATE

V

ENT

/F

LUE

L

OCATION

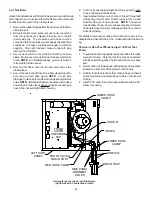

The alternate vent/flue location is the large hole directly

in line with

the induced draft blower outlet. To use the alternate vent/flue loca-

tion refer to the following steps and the “Alternate Vent/Flue Loca-

tion” figure.

NOTE:

Counterflow instructions follow the upflow instructions.

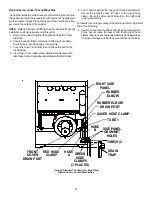

1. Remove and save the four screws securing the vent/flue

coupling to the furnace top panel.

Counterflow

units.

Remove and save the four screws securing the vent/flue

coupling to the furnace basepan. Also remove the three

screws securing the furnace’s internal vent/flue piping to

the blower deck.

2.

Upflow

and

Counterflow

units

.

Loosen the worm gear hose clamps on the rubber elbow

and detach it from both the induced draft blower and the

vent/flue pipe.

3.

Upflow

and

Counterflow

units

.

Remove the vent/flue pipe from the furnace.

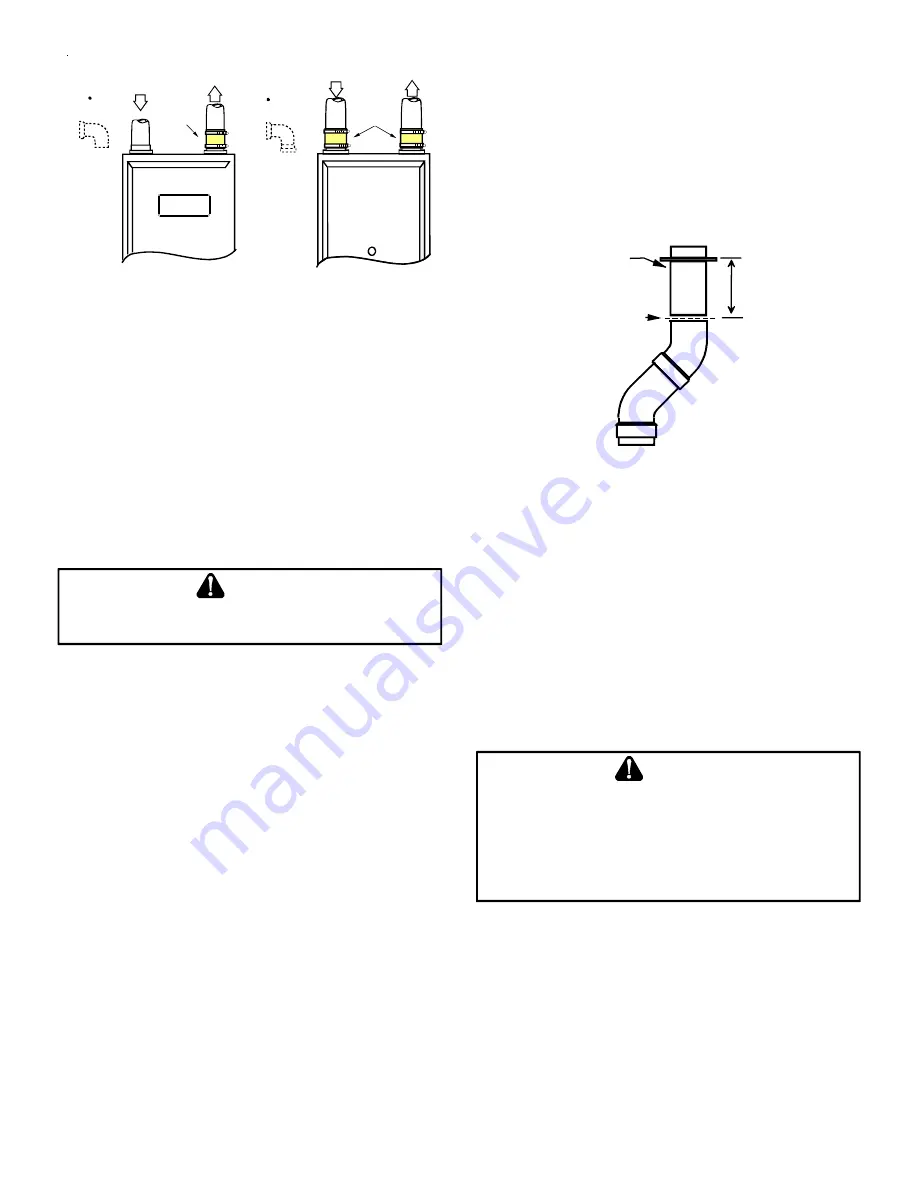

4. Cut the vent/flue pipe 3.75 inches from the flanged end of

the pipe (see “Vent/Flue Pipe Cuts” figure)

.

The section of

pipe attached to the coupling will reach through the side

panel to the induced draft blower. Discard remaining pipe

and elbows.

Counterflow

units.

Cut the vent/flue pipe 3.75 inches from the blower deck

coupling (see “Vent/Flue Pipe Cuts” figure)

.

Save vent/flue

pipe attached to blower deck coupling for use in the alternate

location. Discard remaining pipe and elbows.

FLANGE

CUT

HERE

3.75"

Vent/Flue Pipe Cuts

5. Remove plastic plug from alternate vent/flue location.

Relocate and install plug in standard vent/flue location (top

cover).

Counterflow

units.

Remove plastic plug from alternate vent/flue location.

Relocate and install plug in standard vent/flue location

(basepan). Plug remaining hole in blower deck with plastic

plug included in the drain kit bag.

6.

Upflow

and

Counterflow

units

.

Insert cut section of vent/flue pipe and coupling into alternate

vent/flue location. Using a rubber coupling and worm gear

hose clamps from the drain kit bag, attach the vent/flue

pipe and coupling to the induced draft blower. Secure the

coupling to the cabinet using the screws removed in step 1

or with field-supplied 3/8” #8 self drilling screws.

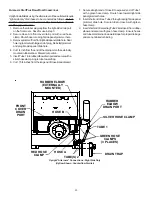

T

HE

RUBBER

ELBOW

IS

NOT

DESIGNED

TO

SUPPORT

A

LOAD

.

W

HEN

THE

RUBBER

ELBOW

IS

MOUNTED

EXTERNALLY

TO

THE

FURNACE

CABINET

,

EXTREME

CARE

MUST

BE

TAKEN

TO

ADEQUATELY

SUPPORT

FIELD

‐

SUPPLIED

VENT

/

FLUE

PIPING

,

AS

DAMAGE

CAN

RESULT

IN

LEAKS

CAUSING

BODILY

INJURY

OR

DEATH

DUE

TO

EXPOSURE

TO

FLUE

GASES

,

INCLUDING

CARBON

MONOXIDE

WARNING

7.

Upflow

and

Counterflow

units

.

For

upright installations

, externally mount the rubber

elbow to the vent/flue coupling using a worm gear hose

clamp. Secure field supplied vent/flue piping to the rubber

elbow using a worm gear hose clamp.

NOTE:

Use of the

alternate vent/flue location for upright installations, requires

the drain trap be installed on the same side of the unit as

the flue pipe.