27

7.

Upflow

and

Counterflow

units

.

For

upright installations

, externally mount the rubber

elbow to the vent/flue coupling using a worm gear hose

clamp. Secure field supplied vent/flue piping to the

rubber elbow using a worm gear hose clamp.

NOTE:

Use of the alternate vent/flue location for upright instal-

lations, requires the drain trap be installed on the

same side of the unit as the flue pipe.

8.

Upflow

and

Counterflow

units

.

For

horizontal installations

, externally secure the

field-supplied vent/flue pipe directly to the vent/flue cou-

pling using a PVC or ABS coupling or elbow.

A

LTERNATE

C

OMBUSTION

A

IR

I

NTAKE

L

OCATION

The alternate combustion air intake location consists of a large,

unobstructed hole (alternate vent connection is aligned with the

Induced Draft Blower). To use the alternate combustion air intake

location, refer to the following steps, and the “Alternate Combus-

tion Air Intake Location” figure.

1.

Remove and save the four screws securing the com-

bustion air intake coupling to the basepan. Remove an

additional three screws securing the furnace’s internal

combustion air intake pipe to the blower deck.

2.

Remove the combustion air intake pipe from the fur-

nace and cut the pipe at the basepan coupling. Save

the basepan coupling and gasket from the blower deck

coupling for use in the alternate location. Discard the

remaining pipe.

3.

Remove plastic plug from alternate combustion air in-

take location. Relocate and install plug in standard air

intake location (basepan). Plug the remaining hole in

the blower deck with the plastic plug included in the

drain kit bag.

4.

With the gasket facing the cabinet side panel, and the

flange’s flat spot facing forward, secure the combustion

air intake coupling to the cabinet using the screws re-

moved in step 1 or with field-supplied 3/8” #8 self -drill-

ing screws.

B

E

SURE

NOT

TO

DAMAGE

INTERNAL

WIRING

OR

OTHER

COMPONENTS

WHEN

REINSTALLING

COUPLING

AND

SCREWS

.

CAUTION

5.

For

non-direct vent installation

s

installed

horizon-

tally

, a minimum of one 90° elbow should be installed

on the combustion air intake coupling to guard against

inadvertent blockage. No elbow is required on the al-

ternate combustion air intake of

upright

installations,

however, a minimum clearance of 2 inches is required

to assure proper air supply.

6.

For

direct vent installations

, secure field-supplied

combustion air intake pipe directly to the air intake

coupling.

NOTE:

A PVC coupling or elbow is required on

counterflow units.

N

ON

-D

IRECT

V

ENT

(S

INGLE

P

IPE

) P

IPING

Non-direct

vent

installations require only a vent/flue pipe. The

vent pipe can be run horizontally with an exit through the side of

the building or run vertically with an exit through the roof of the

building. The vent can also be run through an existing

unused

chimney; however, it must extend a minimum of 12 inches above

the top of the chimney. The space between the vent pipe and the

chimney must be closed with a weather-tight, corrosion-resistant

flashing. For details concerning connection of the vent/flue pipe

to the furnace, refer to

Vent/Flue Pipe and Combustion Air - Stan-

dard Furnace Connections

or

Alternate Furnace Connections

for

specific details. Refer to the following

Non-Direct Vent (Single

Pipe) Piping - Vent/Flue Pipe Terminations

for specific details on

termination construction.

Although

non-direct

vent

installations do not require a combus-

tion air intake

pipe

, a minimum of one 90° elbow should be at-

tached to the furnace’s combustion air intake

if

: an upright instal-

lation uses the standard intake location, or a horizontal installa-

tion uses the alternate air intake location. This elbow will guard

against inadvertent blockage of the air intake.

V

ENT

/F

LUE

P

IPE

L

ENGTHS

AND

D

IAMETERS

Refer to the following table for applicable length, elbows, and pipe

diameter for construction of the vent/flue pipe system of a non-

direct vent installation. In addition to the vent/flue pipe, a single

90° elbow should be secured to the combustion air intake to

prevent inadvertent blockage. The tee used in the vent/flue termi-

nation must be included when determining the number of elbows

in the piping system.

0

1

2

3

4

5

6

7

8

60,000

2

or 2 1/2

250

245

240

235

230

225

220

215

210

80,000

2

or 2 1/2

250

245

240

235

230

225

220

215

210

80,000

3

250

243

236

229

222

215

208

201

194

100,000

2

or 2 1/2

90

85

80

75

70

65

60

55

50

100,000

3

250

243

236

229

222

215

208

201

194

115,000

2

or 2 1/2

75

70

65

60

55

50

45

40

35

115,000

3

220

213

206

199

192

185

178

171

164

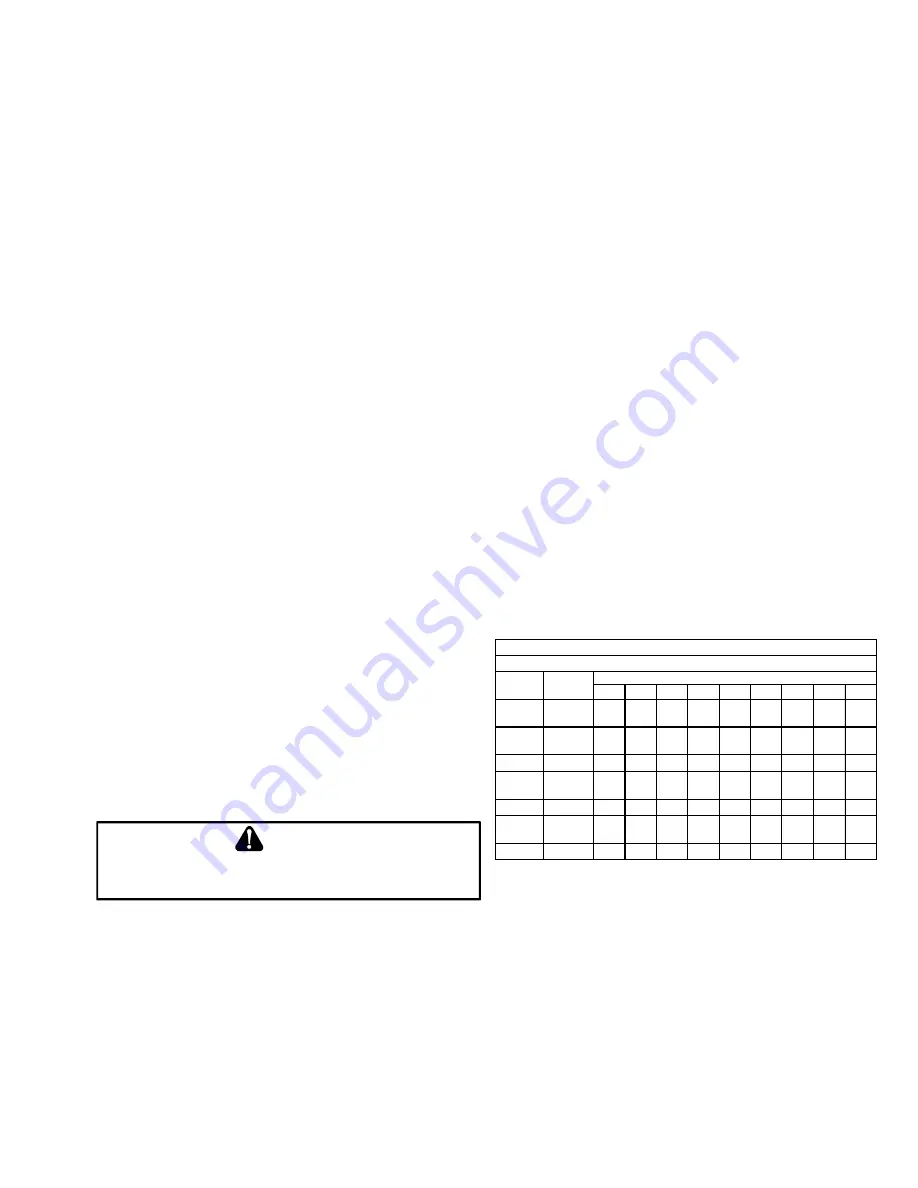

*MVM9/*CVM9 Direct Vent (2 - Pipe) and Non-Direct Vent (1- Pipe)

(6)

Maximum Allowable Length of Vent/Flue Pipe & Combustion Air Pipe (ft)

(1) (2)

Unit Input

(Btu)

Pipe Size

(4)

(in.)

Number of Elbows

(3) (5)

1) Maximum allowable limits listed on individual lengths for inlet and flue

and NOT a combination.

2) Minimum requirement for each vent pipe is five (5) feet in length and

one elbow/tee.

3) Tee used in the vent/flue termination must be included when deter-

mining the number of elbows in the piping system.

4) 2 1/2” or 3” diameter pipe can be used in place of 2” diameter pipe.

5) Increased Clearance Configurations using (2) 45 deg. Elbows should

be considered equivalent to one 90 deg. elbow.

6) One 90° elbow should be secured to the combustion air intake con-

nection.

PRODUCT DESIGN

![Roberts Gorden Combat UHD[S] 150-400 Specifications preview](http://thumbs.mh-extra.com/thumbs/roberts-gorden/combat-uhd-s-150-400/combat-uhd-s-150-400_specifications_1469644-1.webp)