6

Functional Description of Data Logger

The data logger software is designed for configuring and

monitoring Genvex devices. The data logger can be

connected to all Genvex Optima control systems.

The instructions presuppose a correct and

functioning setup of the software.

The user interface in Genvex Data Logger

The data logger can be used for several different purposes:

Setup of parameters in the control system.

Setup and changes to the clock program in the control system.

Reading of the data logger in the control system for the

past three years.

“Live” logging of the current operation of the device.

Subsequent analysis of the operation of a device.

User interface

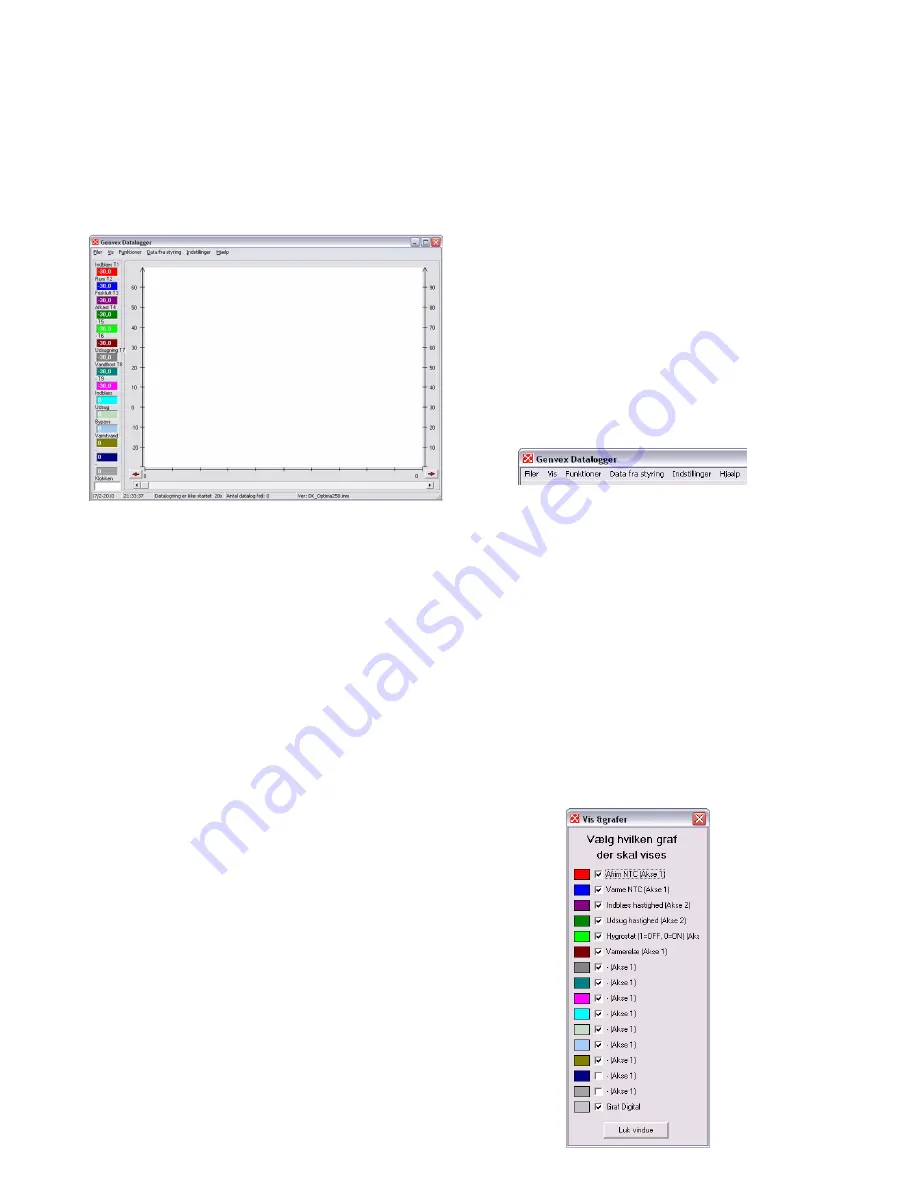

The program is structured with the primary image in the

middle of the screen. This is where the graphs that

represent the information collected from the control

system are displayed. The menu line for the various

settings is placed at the top.

Values that are read “here and now” or values that lie below

the read line are displayed on the left side. The red line

appears when you click a random place on the display.

The figures in the left column will then represent all the

values that lie on the line. The colours of the curves in the

logging area correspond to the colours displayed on the

left-hand side. The exact time of logging will be displayed

in the field at the very bottom.

Tip: Click on the clock field to change the field to display

“LOG NO.”. This can be useful if you want to refer to a

certain logging.

There is an area with grey and white lines at the top of the

logging area itself on the screen. These lines will be red if

relay function is active. Hold the mouse cursor over

the line for a moment, and a small help text will appear.

The left y-axis is a scale for temperatures. The right-hand

side of the logging area is the scale for percentages, e.g.

for fan speeds. The x-axis represents the time line.

A logging can contain a good many pages. This is why

there is a page number in the right/left corner next to the

red arrows. To flip between pages, click the red arrows.

Press and hold the left mouse button for a moment over

the red arrow to open a dialogue box. Here you can enter

the page number you want to scroll to.

There is a status menu located at the bottom of the

screen. This line displays the date and time, if the data

logging has started or stopped, the number of data log

files and which control system the software is

configured for (this is changed in “Settings”).

Menus

Files

Retrieve data*

– Retrieves data saved previously on the hard drive (.txt files)

Import of SD card files* – Imports data saved on the

Optima Design control panel (.dal files)

Save data – Saves the current logging

Save window – Saves only the current window

Save data Excel – save the data to comma separated

value file

Print – Prints the current window

Exit – Exits the software

*The data logger works with .txt files, whereas the control panel works

with .dal files.

View

View graphs – Opens a check box. This provides the

opportunity to select or deselect the graphs displayed

on the screen, usually to provide an overview.